Filling method of solid electrolyte in double-pass AAO template

A technology of solid electrolyte and filling method, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A method for filling solid electrolyte in a double-pass AAO template, comprising the following steps:

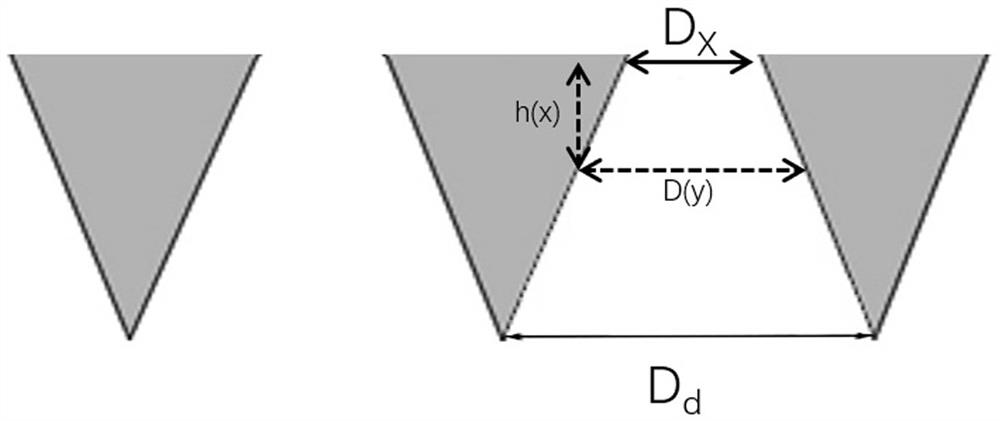

[0026] Step 1. Select a suitable double-pass V-type AAO template as the skeleton of the solid composite electrolyte. The V-type AAO template is a double-pass AAO template with a tapered channel and a narrow opening at the upper end with a diameter of D X , lower end wide opening aperture D d , where D d >D X ; The lower wide opening of the V-shaped AAO template has an aperture of 400 nm, the upper narrow opening has an aperture of 40 nm, and a pore depth of 500 nm.

[0027] Step 2, obtain the SEM topography map of the double-pass V-shaped AAO template channel by SEM, and directly obtain the relationship between the pore diameter D(y) and the pore depth h(x) and the specific pore depth value h according to the SEM topography map T Corresponding aperture value D T , as shown in the table below, basically satisfy the relationship of D(y)=40+0.72h(x).

[0028] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap