Filter for treatment apparatus

A filter and equipment technology, applied in the field of centrifugal filter units, can solve problems such as unsolved problems, and achieve the effect of improving filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

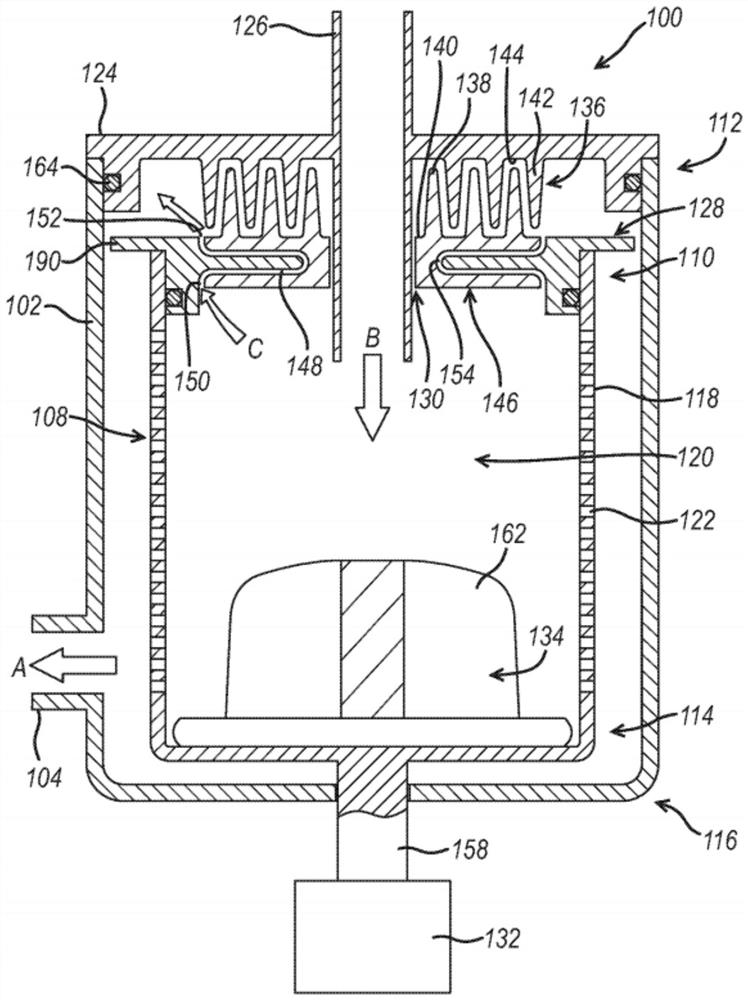

[0256] figure 1 A centrifugal filter unit (100) according to the invention is shown. The centrifugal filter unit (100) includes a housing (102) having an outlet (104) to enable filtered treatment formulation (shown by arrow A) to exit the centrifugal filter unit (100) through the outlet. The centrifugal filter unit (100) includes a filter (108) rotatably mounted in a housing (102). The filter (108) has a first end (110) proximate the first end (112) of the housing (102). The filter has a second end (114) proximate to a second end (116) of the housing (102). The filter has a sidewall (118) disposed between the first end (110) and the second end (114), with perforations (122) formed in the sidewall (118). The centrifugal filter unit (100) has a filter chamber (120). A cover (128) is located at the first end (110) of the filter. The cover (128) has a hole (130) that can be used to position the inlet (126) formed on the end cap (124), but the cover (128) substantially seals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com