Straw provocation device after tractor tire compacts straw

A technology for tractors and straws, which is applied in the field of straw prodding devices, can solve the problems of easy safety accidents, easy hitting of hard stones in the field, and adjustment, so as to improve the operation quality, ensure the operation effect and life, and be simple and convenient to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

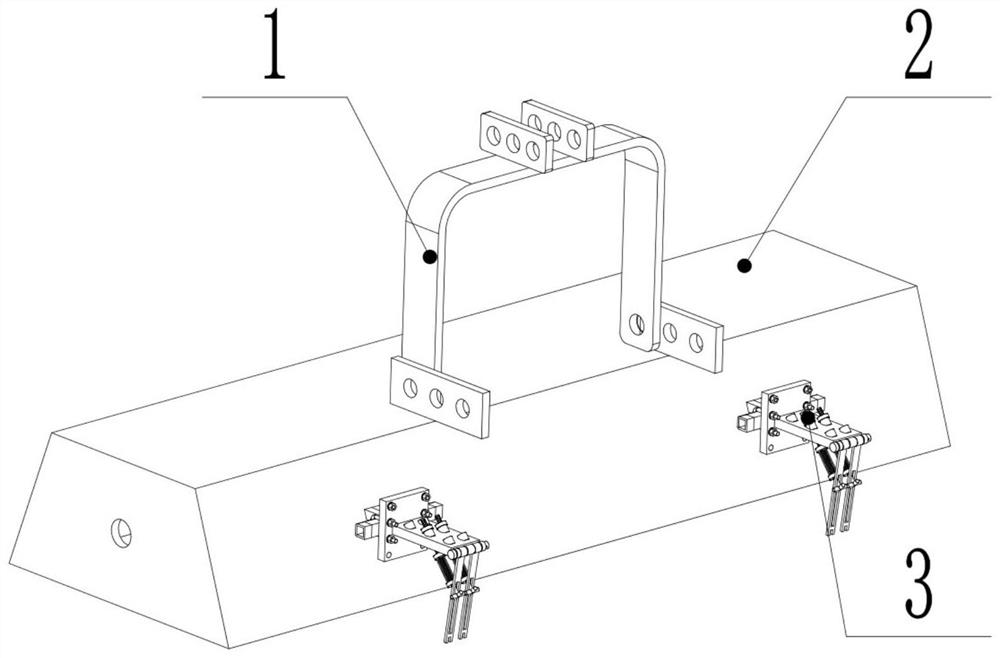

[0061] Such as figure 1 As shown, a straw provocation device of the present invention after tractor tires have compacted the straw is arranged between the rear wheel of the tractor and the straw returning machine. A plurality of stalk picking devices 3 are installed on the front end surface of the returning machine casing 2 (the end surface facing the side of the tractor) corresponding to the tractor rut. The field return casing 2 is provided with a three-point hitch 1 articulated with the tractor.

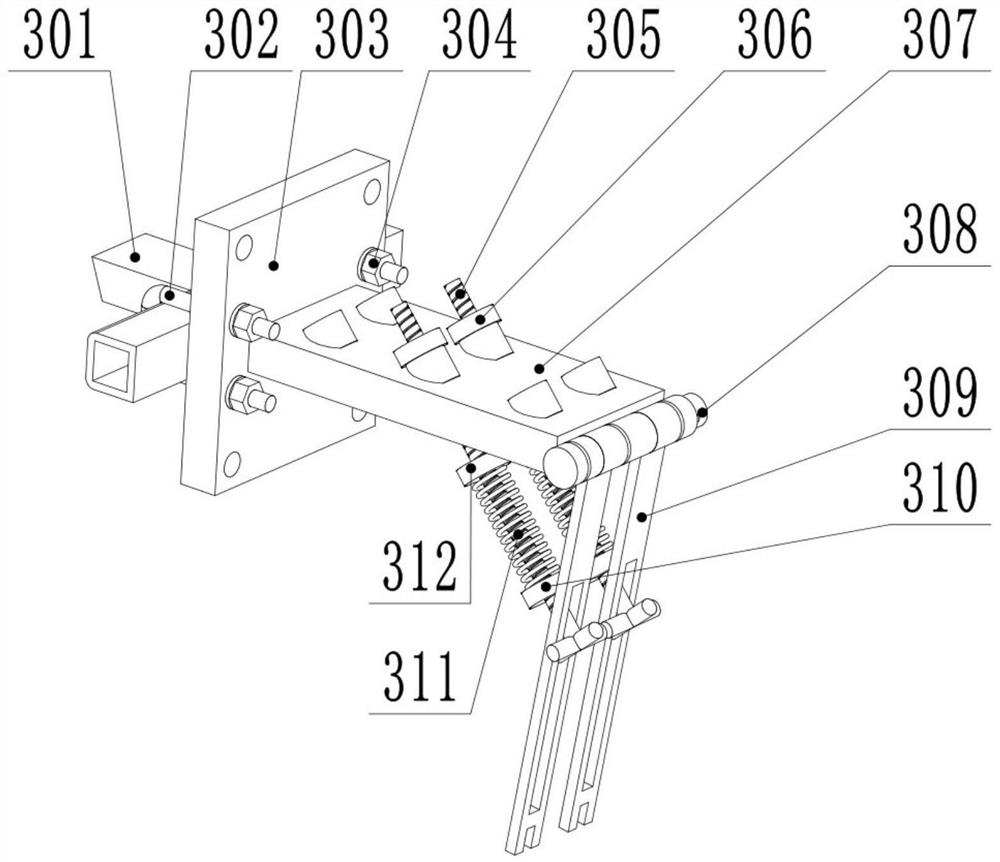

[0062] Such as figure 2 As shown, the straw picking device 3 includes a fixed square steel 301, a "U"-shaped card 302, a fixed plate 303, a spring threaded pressure rod 305, a threaded disc 306, a support plate 307, a rotating pin 308, a toggle plate 309, Spring pressing block 310, spring 311 and threaded pressing block 312.

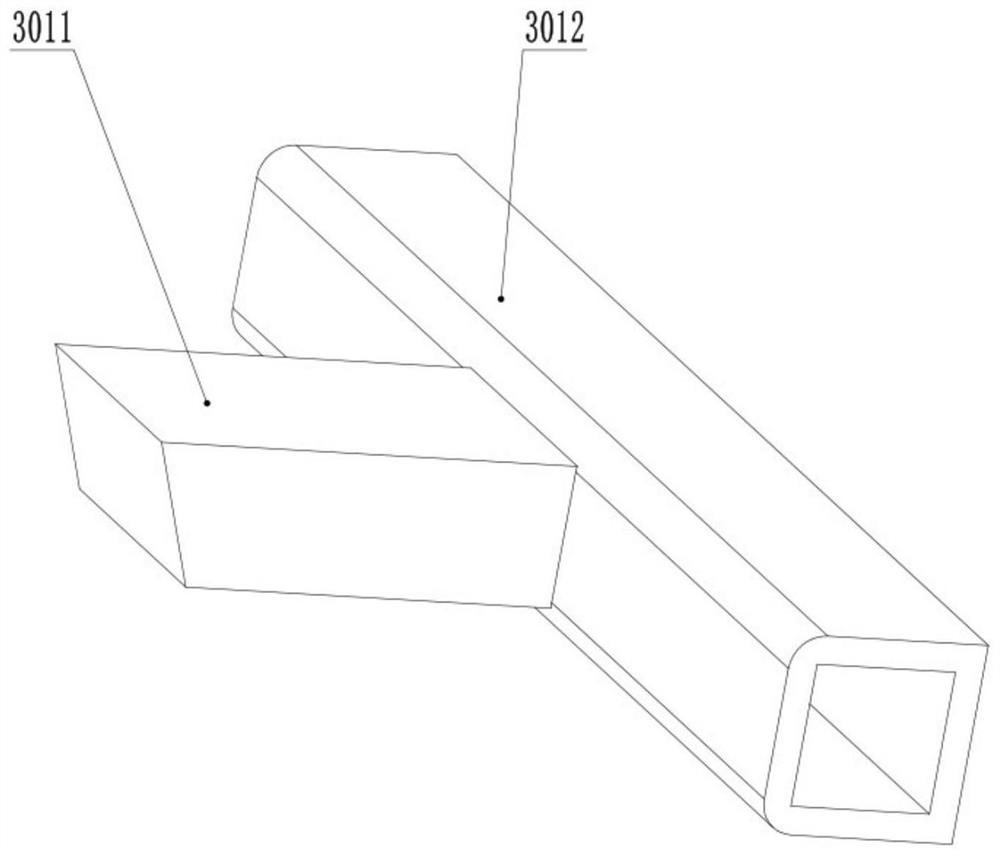

[0063] Such as image 3 As shown, the fixed square steel 301 includes a rounded square steel 3012 and a fixed sloping plate 3011 vertically fixed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com