Gas-liquid two-phase flow distributor and gas-liquid two-phase flow distribution method

A gas-liquid two-phase flow and distributor technology, which is applied in chemical instruments and methods, mixing methods, fluid mixers, etc., can solve the problem of inability to accurately distribute gas-liquid two-phase flow in proportion, and achieve uniform distribution , simple structure and operation, single phase distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

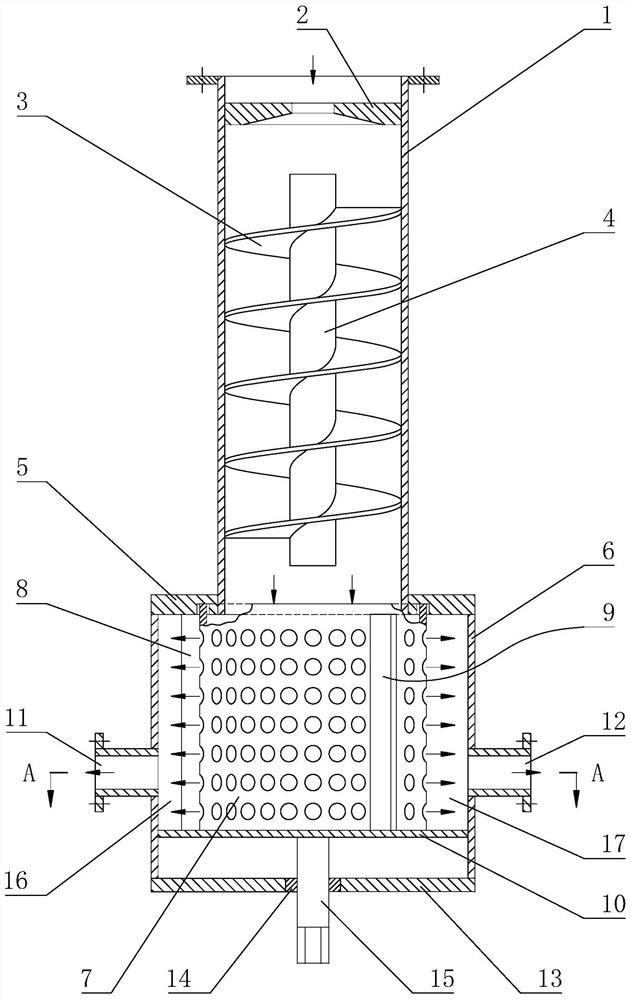

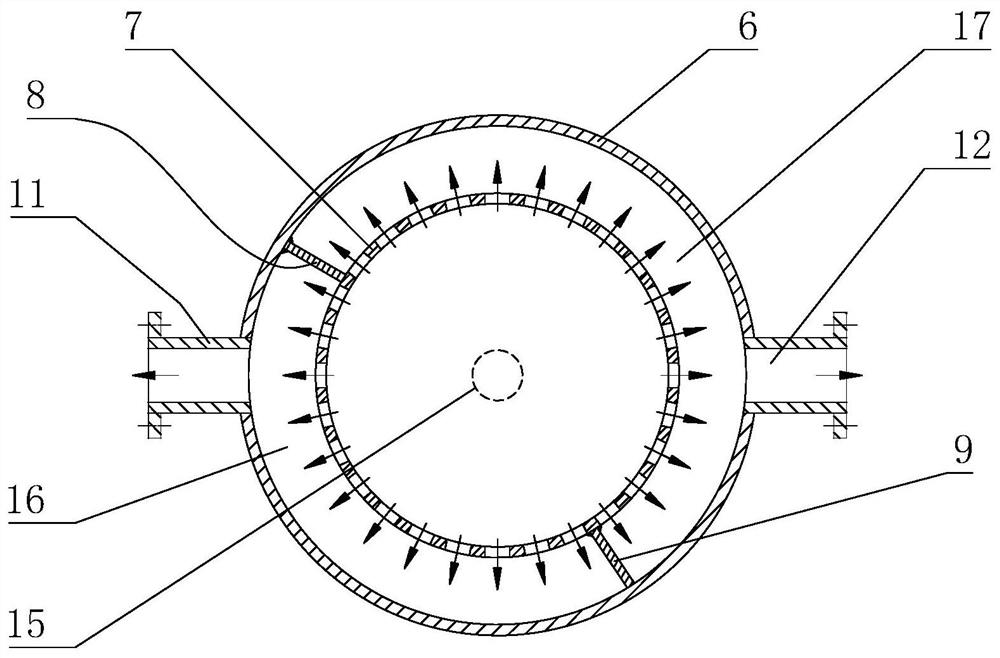

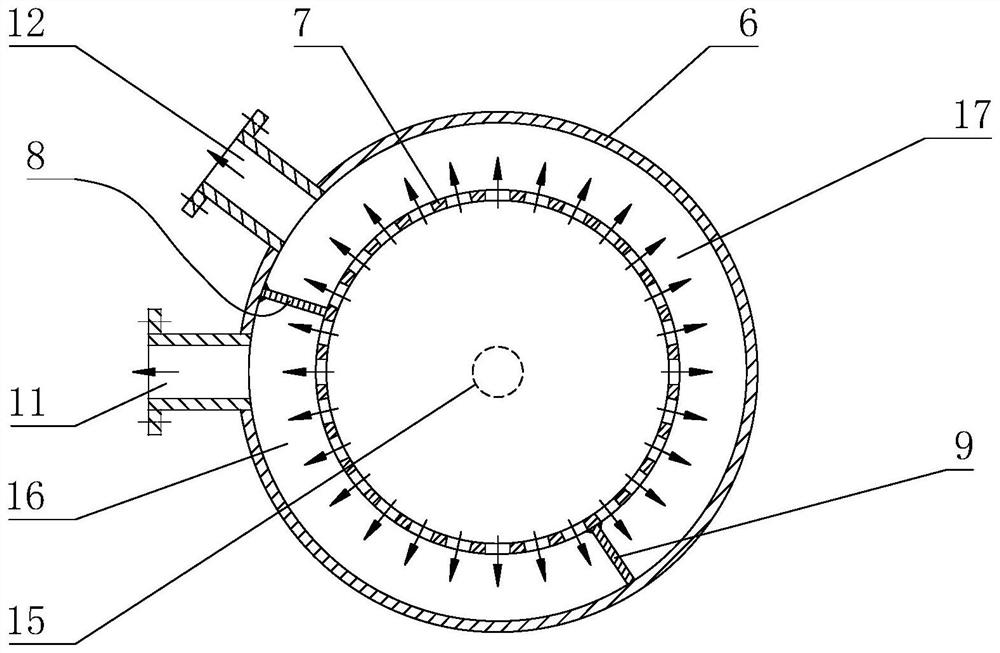

[0014] see figure 1 with figure 2 , The gas-liquid two-phase flow distributor of the present invention (referred to as the distributor for short) is provided with a mixing tube 1, and a spiral plate 3 is arranged in the mixing tube 1 along the axial direction. The inner side of the spiral plate 3 is connected (welded) to the outer surface of the rod 4, the outer side is connected to the inner surface of the mixing tube 1 (welded), and the outer surface of the two adjacent spiral plates 3 and the rod 4 are connected to the mixing tube 1. A spiral flow channel is formed between the inner surfaces of the pipe 1 . The rod 4 is generally a cylindrical steel rod. A throttling orifice 2 is arranged near the entrance of the mixing tube 1 , and the throttling orifice 2 is generally a standard part welded on the inner surface of the mixing tube 1 . The outlet of the mixing tube 1 is provided with a mixing tube outlet plate 5 , and the outlet of the mixing tube 1 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com