Bridge convenient to overhaul

A bridge and shell technology, which is applied to the field of bridges that are easy to maintain, can solve the problems of time-consuming and laborious handling, installation and disassembly of the cover plate, dangerous installation, and occupying installation space, and achieves reduced deformation, high safety, and improved use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

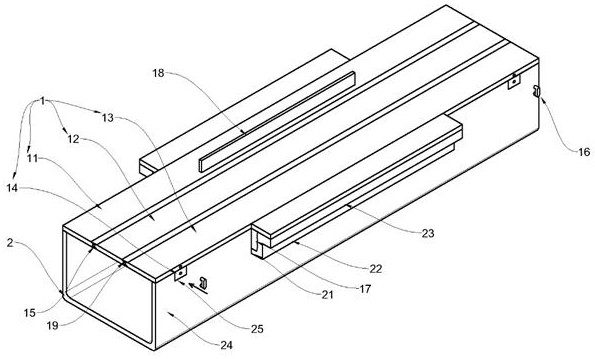

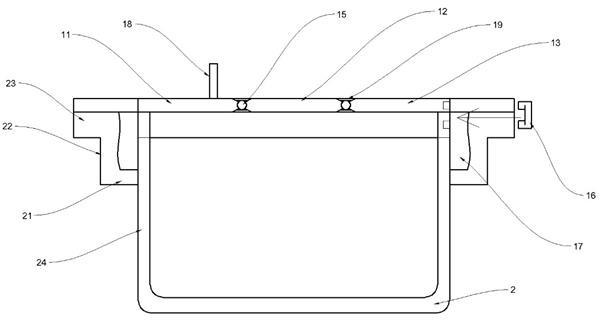

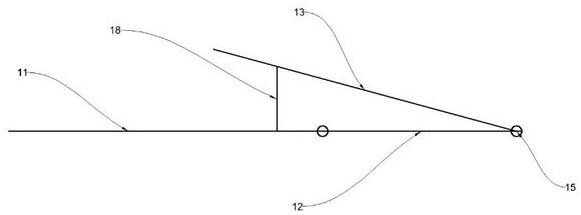

[0022] Such as Figure 1-Figure 4 As shown, the bridge frame convenient for maintenance disclosed by the present invention includes a "U"-shaped housing 2 for placing cables, and a cover plate 1 (aluminum alloy material) that seals the upper opening of the housing 2, wherein the housing 2 can be integrated The manufactured shell can also be formed by combining multiple plates; the cover plate 1 includes two beams 14, a left panel 11, a middle panel 12 and a right panel 13; the two beams 14 are located near the front and rear ends, and the housing 2 The corresponding position of the side wall is provided with a wall groove 25 for pressing the crossbeam 14; the three panels are arranged sequentially on the crossbeam 14, and the three panels are connected by rotating shaft 15; the left panel 11 is fixedly connected with the crossbeam 14, and the middle panel 12 and the right panel 13 and the crossbeam 14 are lapped together, and the right side end surface of the right panel 13 an...

Embodiment 2

[0028] Such as Figure 5 , Figure 6 As shown; this embodiment has made the following improvements on the basis of Embodiment 1: the upper edge of the inner surface of the support plate 18 is connected to the magnetic adsorption plate 181 in rotation, and the magnetic adsorption plate 181 is connected to the inner surface of the support plate 18 through the elastic connector 183 Fixedly connected, the middle panel 12 and the right panel 13 are embedded with a ferromagnetic adsorption part 182 at the position corresponding to the pressure contact surface of the magnetic adsorption plate 181 after rotation. Through the design of the magnetic adsorption plate 181 and the ferromagnetic adsorption part 182, the flipped middle panel 12 and the right panel 13 are in a stable fixed state. Adjust the adsorption according to the flip angle, flexible and changeable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com