Adjustable slitting equipment special for model manufacturing

A model manufacturing and adjustable technology, applied in the direction of manufacturing tools, metal processing equipment, large fixed members, etc., can solve the problems of inconvenient work, reduced work efficiency, heavy model weight, etc., and achieve the effect of stable cutting process and easy retraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

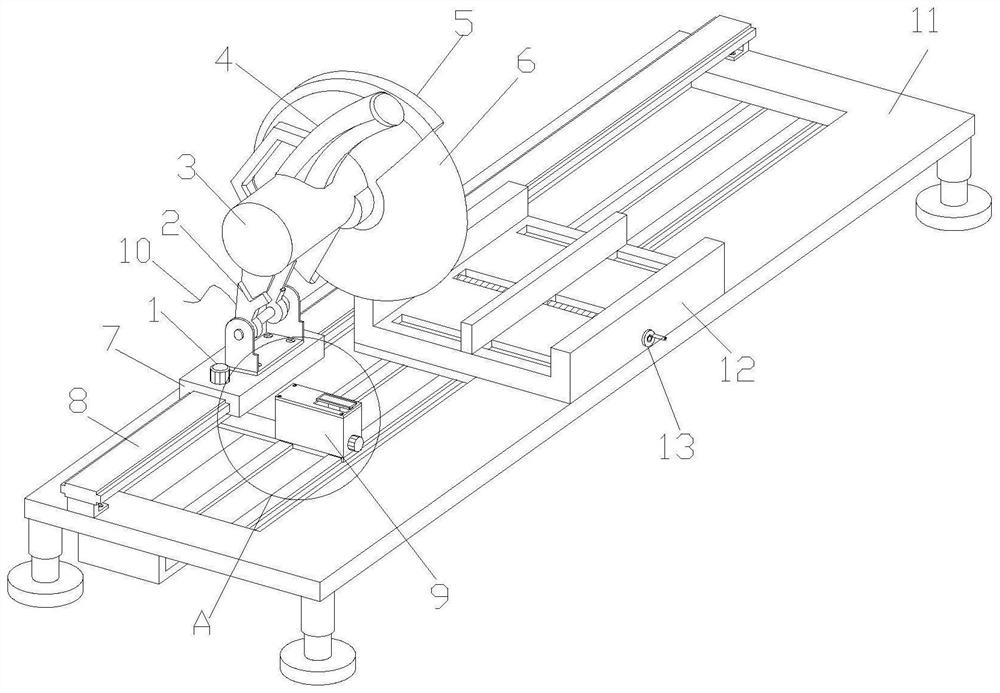

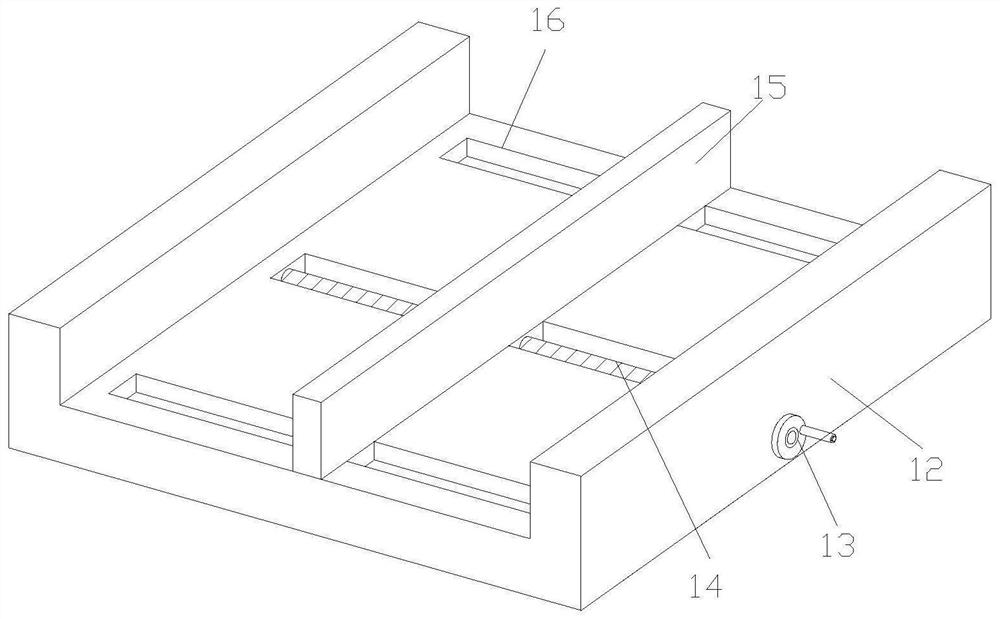

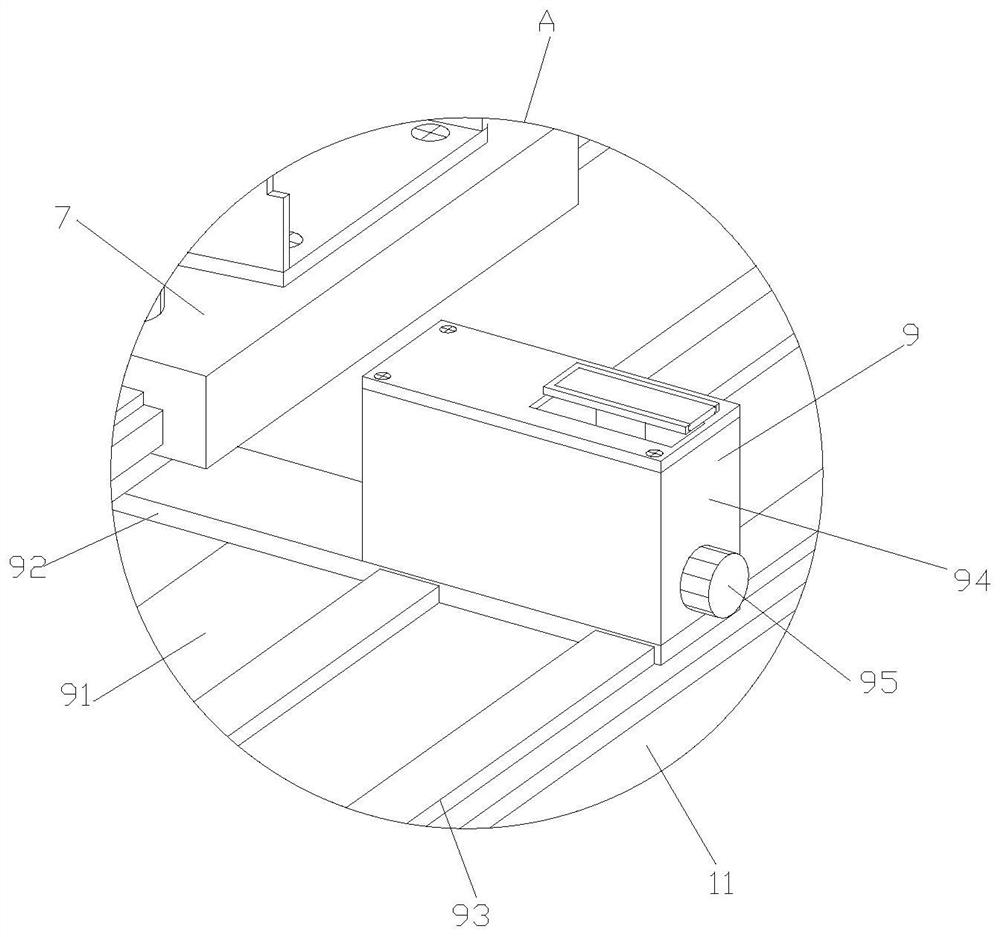

[0030] see figure 1 and figure 2 , the present invention provides a special adjustable cutting device for model manufacturing through improvement, including a fixed screw 1, a support frame 2, a power cord 10 and a base 11, and a screw hole provided at the rear end of the fixed screw 1 and the top surface of the sliding frame 7 The inner thread connection, the support frame 2 is hinged on the inner top of the sliding frame 7, and the top surface of the support frame 2 is fastened with the motor 3, the front end surface and the top surface of the motor 3 are respectively locked with the protective cover 5 and the handle 4, and the front end of the motor 3 outputs The shaft passes through the rear end of the protective cover 5 and is fixedly connected to the inner ring of the cutting piece 6. The sliding frame 7 is slidably installed on the guide rail 8 locked on the left end of the top surface of the base 11. The power cord 10 is connected to the power input end of the motor 3...

Embodiment 2

[0034] The present invention provides an adjustable slitting equipment for model manufacturing through improvement. The inner end surface of the protective cover 5 covers the outer middle and upper end of the cutting piece 6, which is convenient for protecting the cutting piece 6 and preventing the workers from touching the cutting piece. 6, the handle 4 is an arc-shaped rod that tapers from bottom to top.

[0035] The present invention provides a special adjustable cutting equipment for model making through improvement, and its working principle is as follows;

[0036] First, first connect the power cord 10 to the external controller, then place the model that needs to be cut between the front end face of the splint 15 and the inner front end face of the U-shaped fixed plate 12, and then turn the turntable 13 to drive the screw rod 14 Rotate, so that the splint 15 is driven by the screw 14 to move to the left to clamp the model;

[0037] Second, start the motor 3 by the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com