Reticulation type screw extractor

A technology of extractor and screw, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of screw extraction failure, inability to achieve, easy to damage installation screws, etc., to avoid destructive damage, easy operation, and quick removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

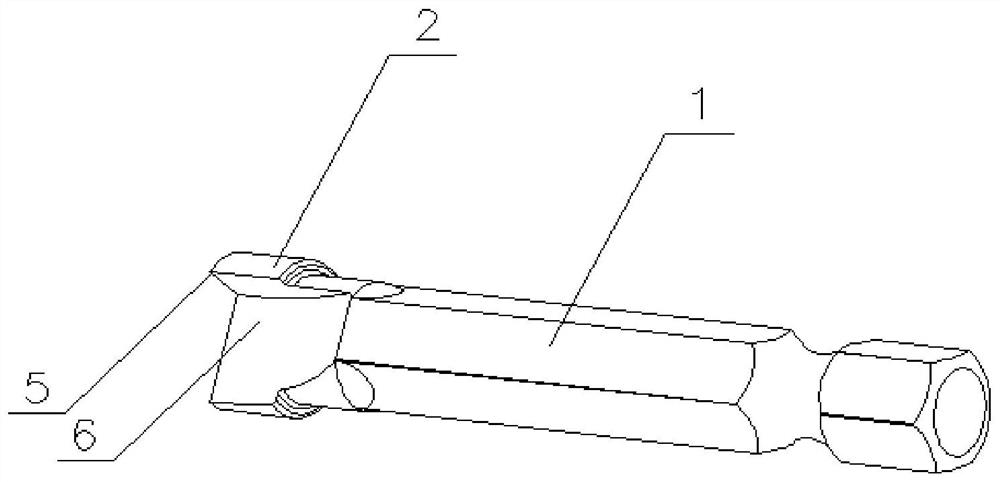

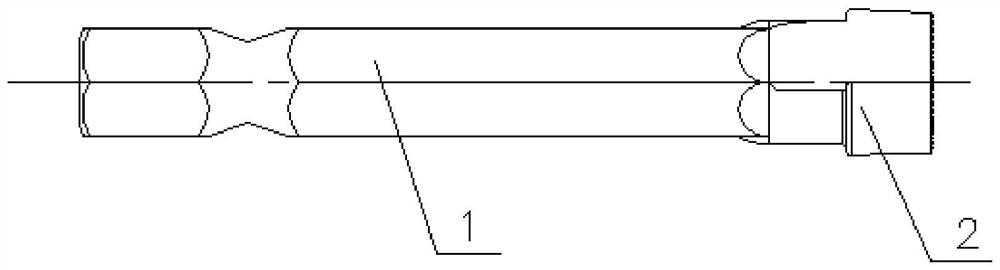

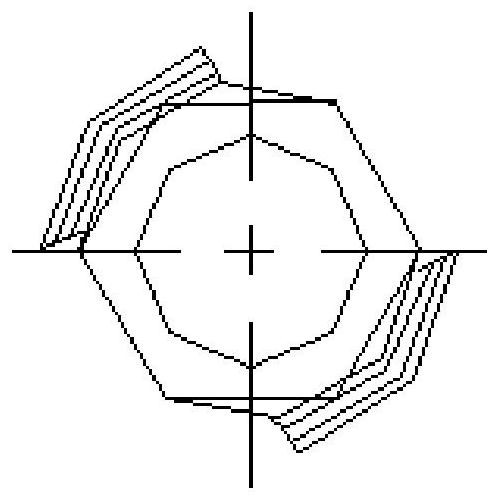

[0023] Embodiment: A textured screw 4 extractor, including extractor head 1 and operating rod 2, the operating rod 2 is integrally formed on one end of the extractor head 1, and the end surface of the other end of the extractor head 1 Just able to closely fit the surface of the head of the one-way screw 4, the end surface of the other end of the head 1 of the extractor is provided with a number of bumps 3, and the bumps 3 can just be engaged with the head surface of the screw 4. When in use, the extractor head 1 is pressed against the head of the one-way screw 4, and the convex point 3 on the extractor head 1 is engaged with the head of the one-way screw 4 for positioning. The extractor head 1, the one-way screw 4 rotates synchronously with the extractor head 1 to achieve the effect of reverse rotation and disassembly of the one-way screw 4. The screw 4 extractor of this structure is simple in structure, easy to operate, and can realize one-way The screw 4 is quickly disassemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com