A decomposition mechanism for mating components

A technology for decomposing mechanisms and components, which is applied in the manufacture of tools and hand-held tools, etc., which can solve the problems of large manpower and material consumption, scrapping of outer casings, and occupation of equipment, so as to reduce difficulty, shorten the matching cycle, and avoid destructive damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

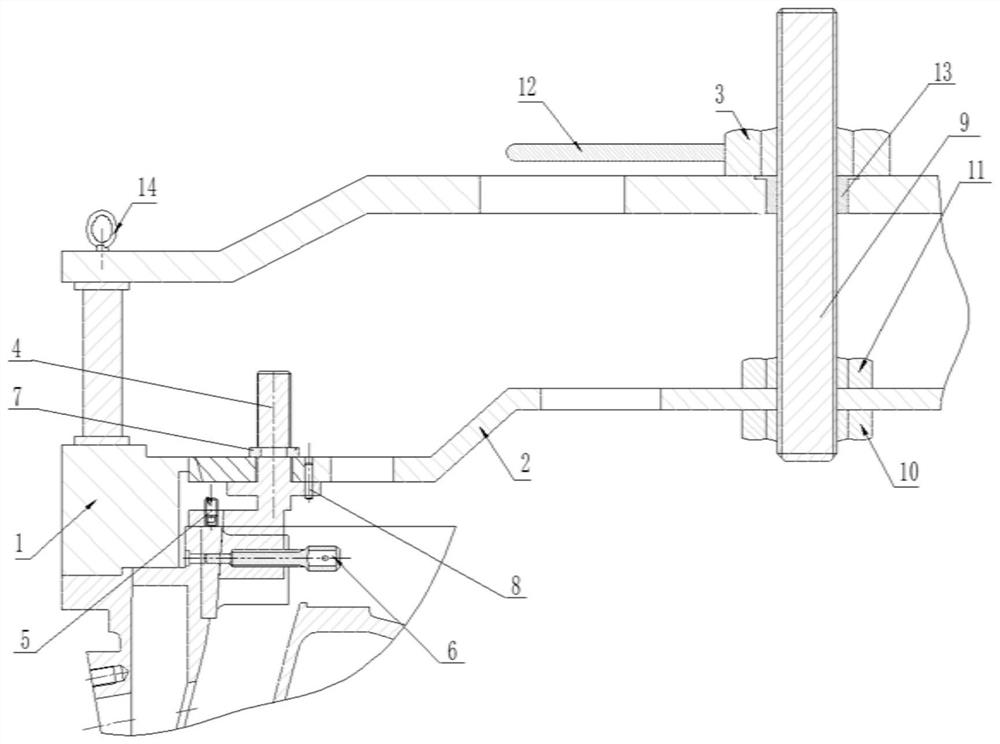

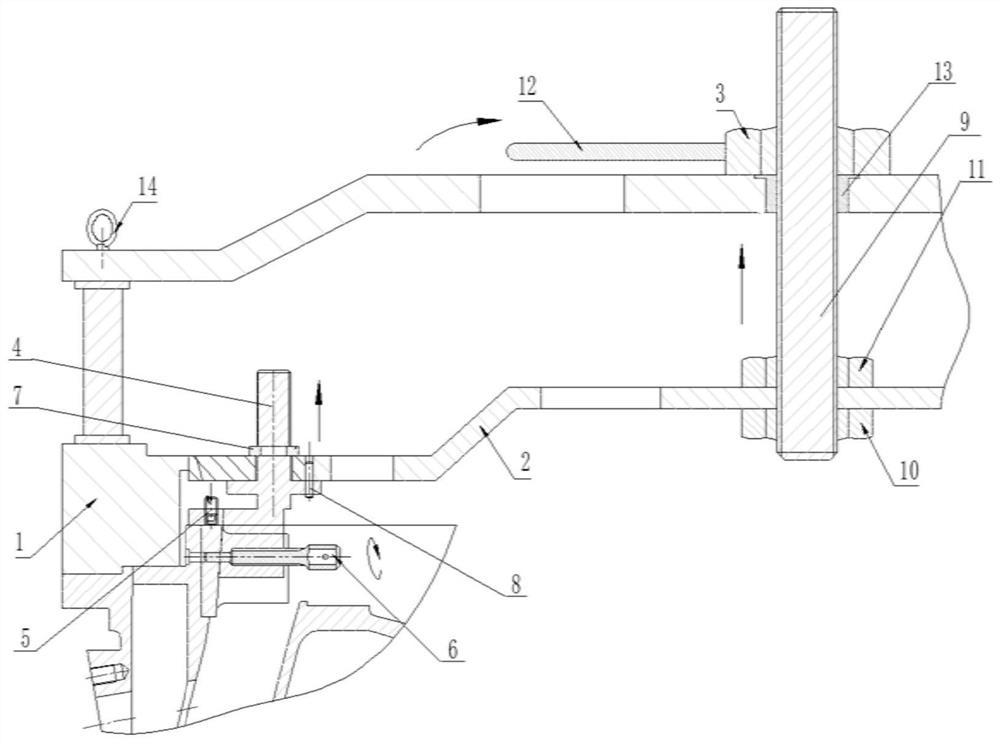

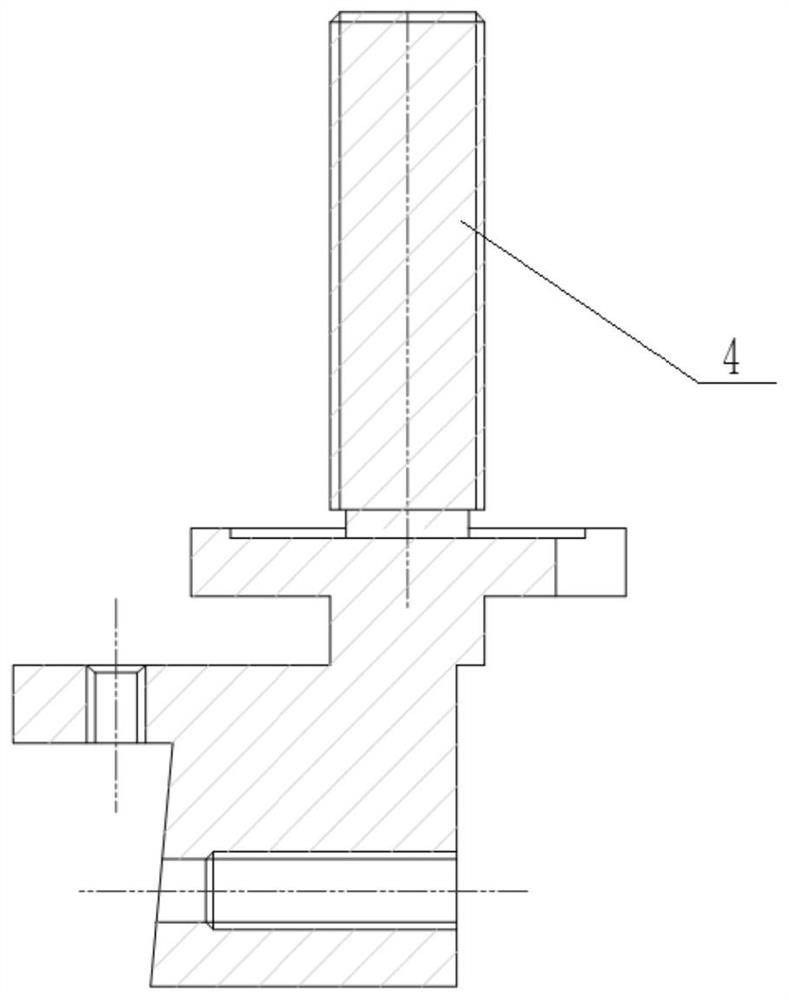

[0047] Take the decomposition of the high-pressure inlet guide of the gas generator as an example: the guide is assembled with the outer casing through thermal assembly, and after the 8 guide pins in the radial direction are disassembled, 8 guide pin holes are left on the outer ring. 4 Select the pin-type structure, manually insert the pin 6 into the guide pin hole of the guide (depth 9mm ~ 12mm), tighten the screw 5 (adjustment range 3mm ~ 8mm), connect the puller 4 and the guide together, insert the pin 8. To prevent the blade from being rotated and damaged by the pulling head 4, tighten the lock nut 7, connect the connecting plate 2 and the pulling head 4 together, the end surface of the pulling head 4 is attached to the connecting plate 2, check that the 0.02mm feeler gauge does not pass through the seam, Ensure that the 4-axis of the head is vertically upward. Repeat the above steps to sequentially connect and fix the 8 pulling heads 4 with the connecting plate 2 to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com