A method for controlling the temperature of molten iron in the production process of argon-oxygen refining ferroalloy

A technology of production process and molten iron temperature, applied in the direction of self-adaptive control, general control system, control/regulation system, etc., can solve the problems that the smelting temperature of AOD furnace cannot be measured in real time, and the quality of smelting ferroalloy cannot be guaranteed, and achieve real-time control. Good, simple algorithm, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

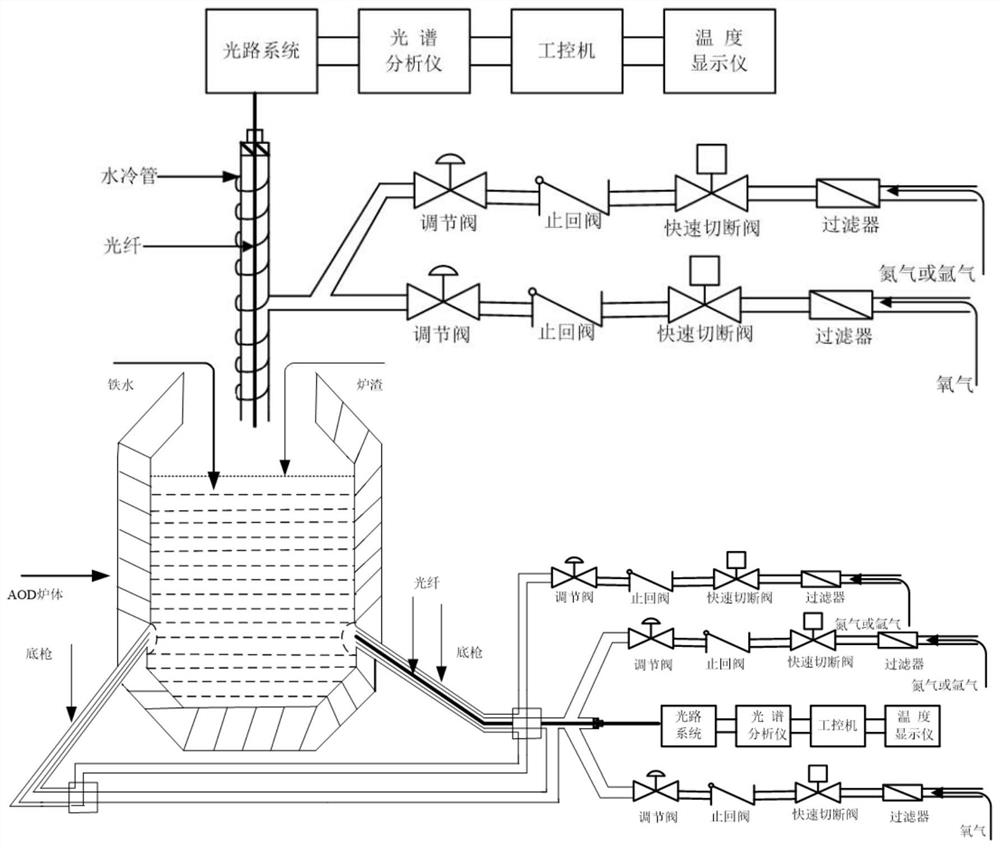

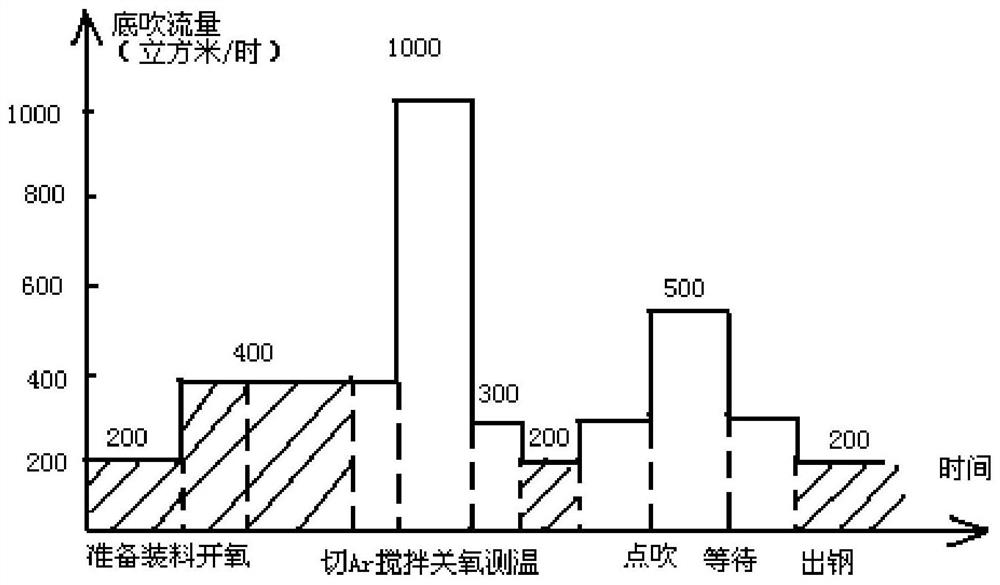

[0028] see Figure 1 to Figure 3 Shown:

[0029] Step 1. First, determine the caliber of the gas supply pipeline according to the smelting tonnage of the AOD furnace, and then select and install the regulating valve and flowmeter according to the caliber of the pipeline. The regulating valve and flowmeter must meet the requirements for gas flow regulation and measurement, and the transmitter adopts 485 communication protocol to simplify the controller hardware circuit design.

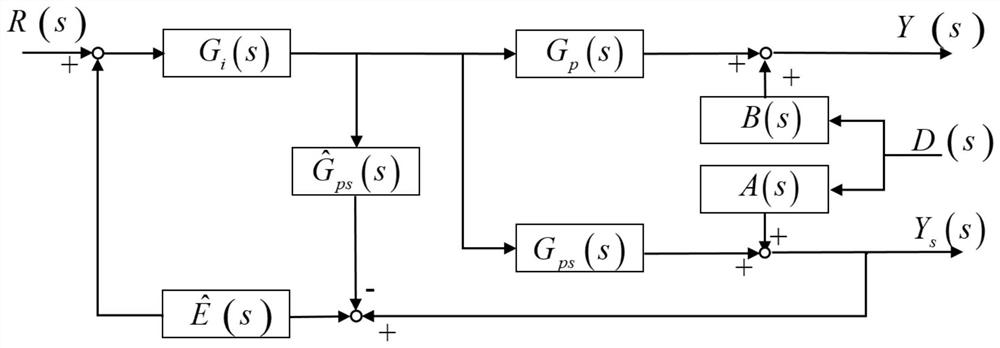

[0030] Step 2. Establish the main channel mathematical model and the disturbance channel mathematical model of the influence of disturbance on the main output according to the heat release principle of the oxidation reaction, then establish the auxiliary channel mathematical model according to the operating characteristics of the regulating valve, and finally use the BP neural network method to establish the influence of disturbance on the auxiliary output The perturbed channel mathematical model of . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com