Mixed gas steaming setting machine

A technology of setting machine and mixed gas, which is applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of complicated finishing process steps, high cost and high energy consumption, so as to reduce production costs and save energy. Electric energy, the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

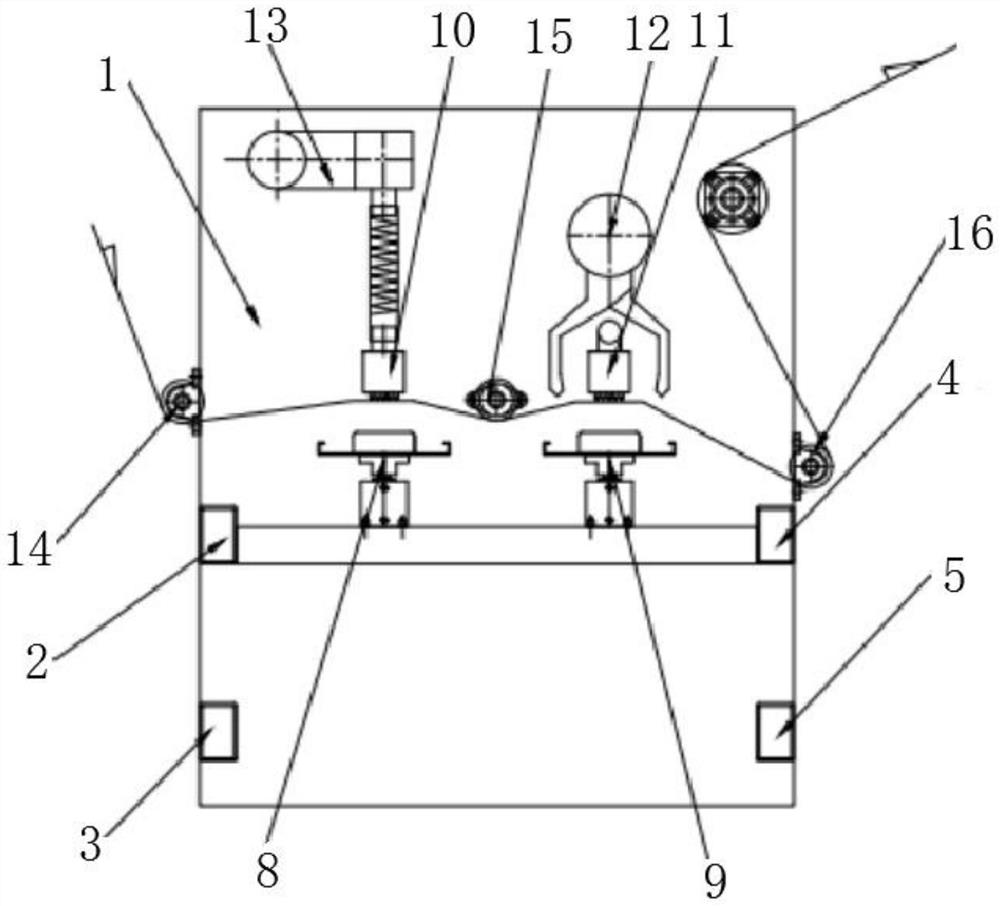

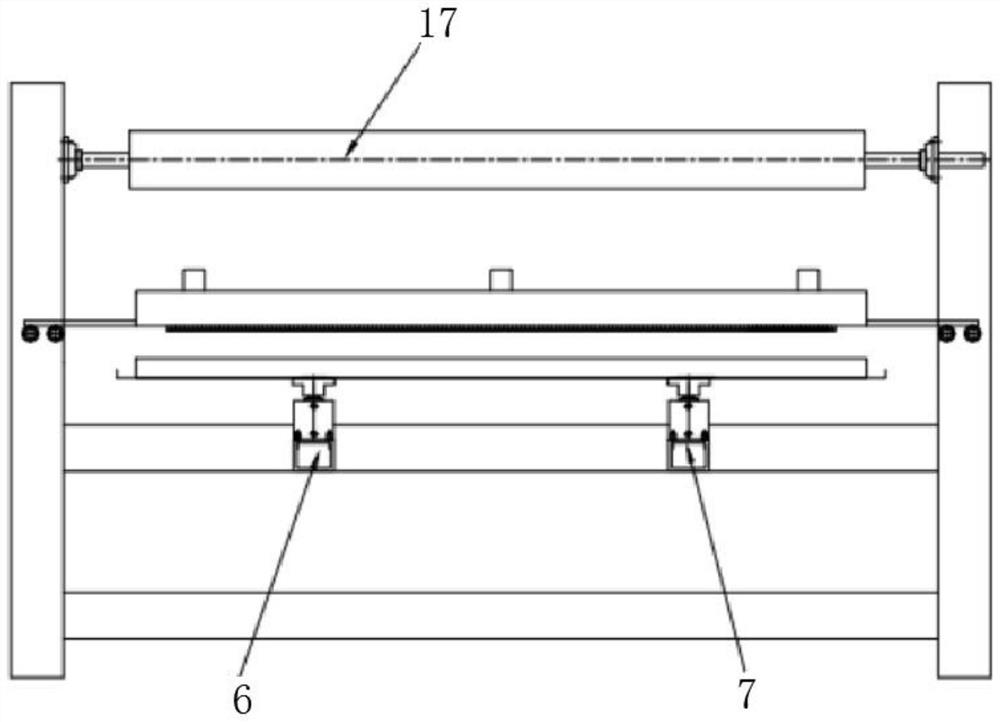

[0022] see Figure 1-2 , the present invention provides the following technical solutions: a mixed steam setting machine, including a frame 1, and the inside of the frame 1 is respectively fixed with a first brace 2, a second brace 3, a third brace 4 and a fourth brace Block 5, the second block 3 is located directly below the first block 2, the fourth block 5 is located directly below the third block 4, and the first block 2 and the third block 4 are respectively fixed with the first block 2 A tray support 6 and a second tray support 7, the inside of the frame 1 is respectively provided with a first tray body 8 and a second tray body 9, the first tray body 8 and the second tray body 9 are arranged on the corresponding first tray On the support 6 and the second tray support 7, the inside of the frame 1 is provided with a first steaming rack 10 and a second steaming rack 11, the first steaming rack 10 is arranged directly above the first tray body 8, and the second steaming rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com