Tension test device and test method for copper wires

A technology of tension test and stretching device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems that the test efficiency cannot meet the actual needs, there are many repeated procedures, and the test efficiency is low. Achieve the effect of eliminating manual transfer, strong continuity, and ensuring transfer stability and accuracy

Active Publication Date: 2020-10-13

KUNSHAN PINZHI METAL MATERIAL CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In the prior art, copper wire generally adopts a tensile test instrument to carry out the strength test of copper wire, although the copper wire tensile tester can automatically obtain the maximum test force, breaking force, yield force, tensile strength, compressive strength, bending Strength, elastic modulus, elongation, constant elongation stress, constant stress elongation and

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

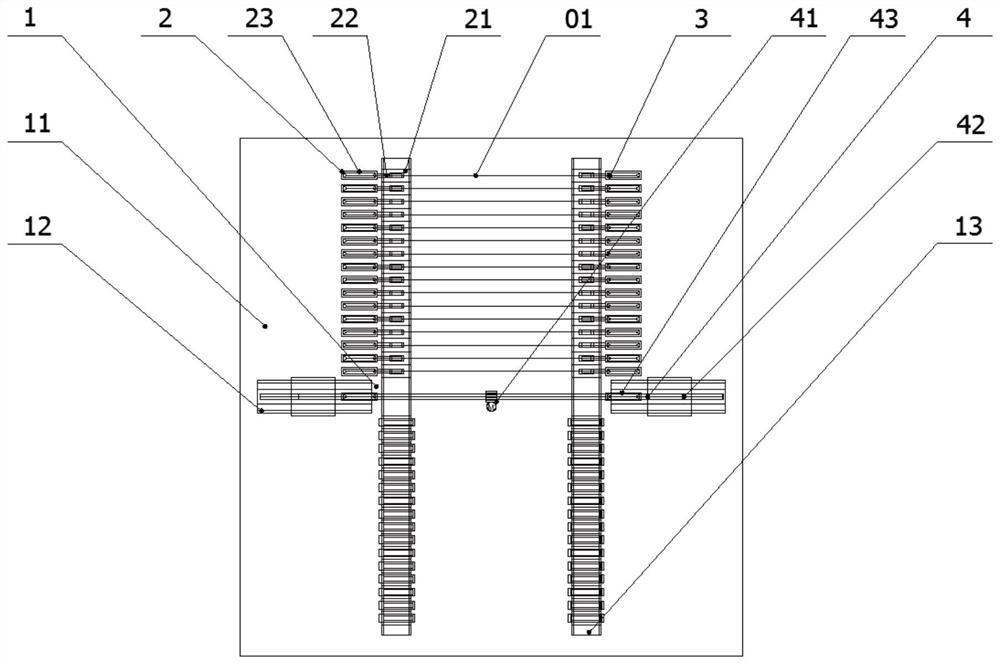

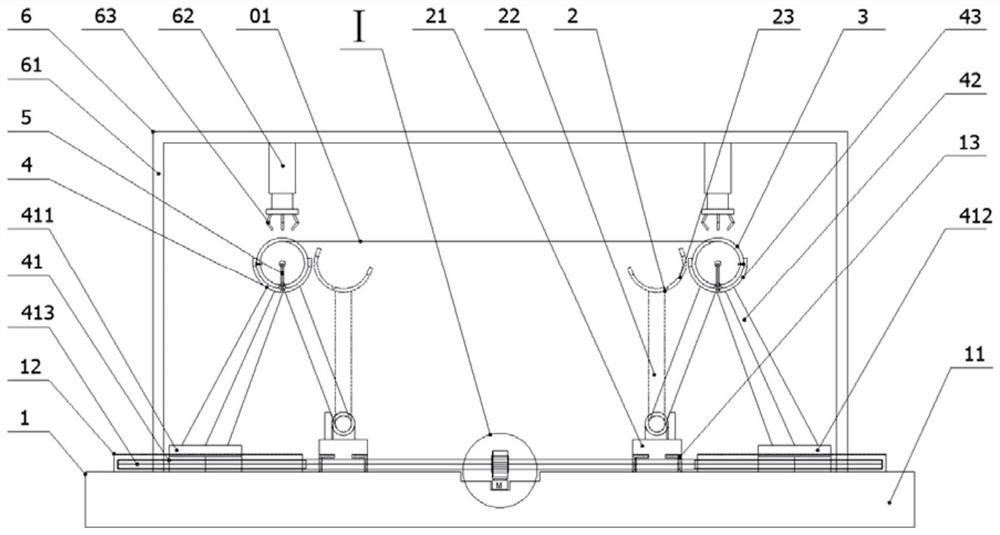

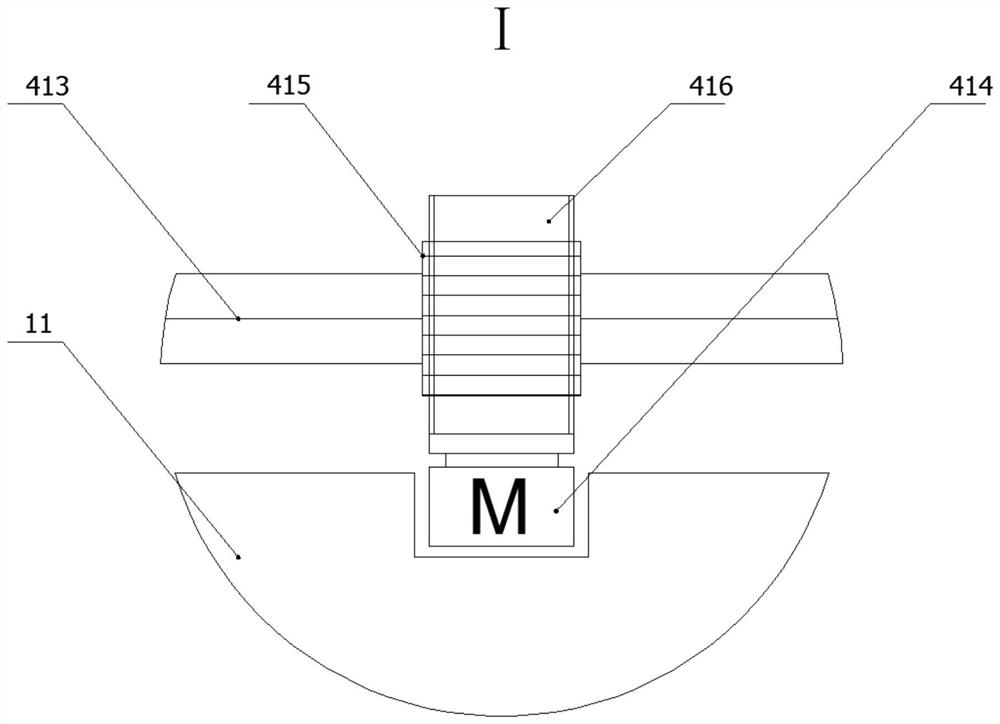

The invention discloses a tension test device for copper wires. The device comprises a test platform, a transfer device, a copper wire fixing assembly, a stretching device and a tension metering device. The test platform is arranged at the lowest end; the transfer device and a transfer rail are correspondingly arranged; the copper wire fixing assembly and the transfer device are correspondingly arranged; the stretching device is arranged corresponding to the stretching rail; the tension metering device is used for metering a tension value of the copper wire in a stress disconnection process; and the transfer rail is arranged on the test platform, and the transfer device is introduced so that the plurality of transfer devices can be sequentially arranged and transferred, and a continuous tension test on the copper wires is facilitated. Besides, an independent structure convenient to assemble and disassemble is arranged between the copper wire fixing assembly and the transfer device so that the copper wire can be fixed and erected on the transfer device in advance, and preparation is made for a tension test.

Description

technical field [0001] The invention relates to the technical field of metal wire index detection, in particular to a tensile test device and a test method for copper wires. Background technique [0002] Copper wire refers to the thin wire drawn from thicker copper wire, which can be used for wire cutting wire, cable wire, copper brush filter, etc. It is widely used in wire cutting and power transmission. In the process of use, the wire will inevitably be subjected to various bending and pulling according to the needs. Therefore, the tensile strength of the copper wire is a very important performance index for the copper wire. [0003] In the prior art, the copper wire is generally tested for the strength of the copper wire by a tensile testing instrument, although the copper wire tensile testing instrument can automatically obtain the maximum test force, breaking force, yield force, tensile strength, compressive strength, bending strength Strength, elastic modulus, elongat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08G01N3/04

CPCG01N3/08G01N3/04G01N2203/028

Inventor 封昌干龙新科

Owner KUNSHAN PINZHI METAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com