Lamp box mounting structure for exhibition hall design

A technology for installing structures and light boxes, which is applied to display devices, mechanical equipment, instruments, etc., can solve the problems of large wall damage, troublesome disassembly, unfavorable protection of exhibition hall walls, etc., and achieve the effect of improving practicability and avoiding wall damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

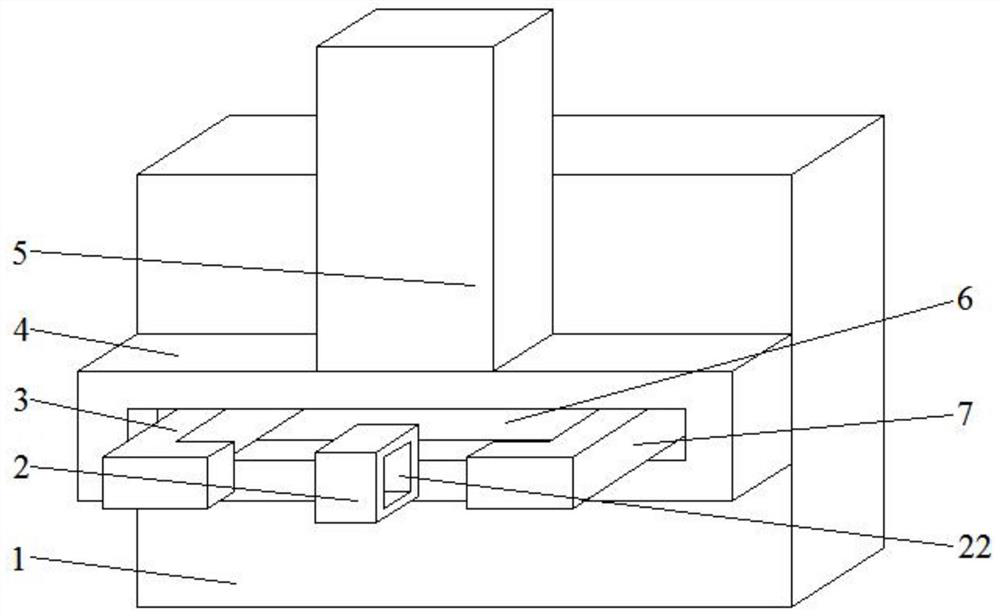

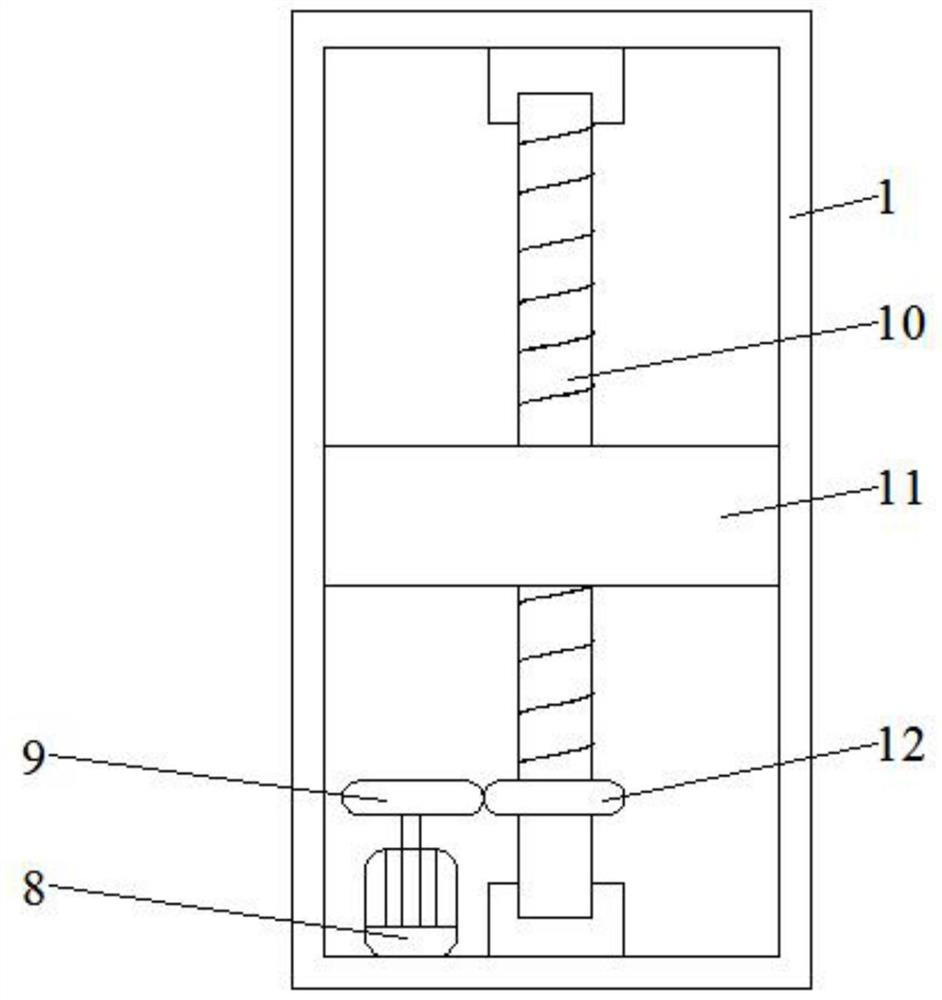

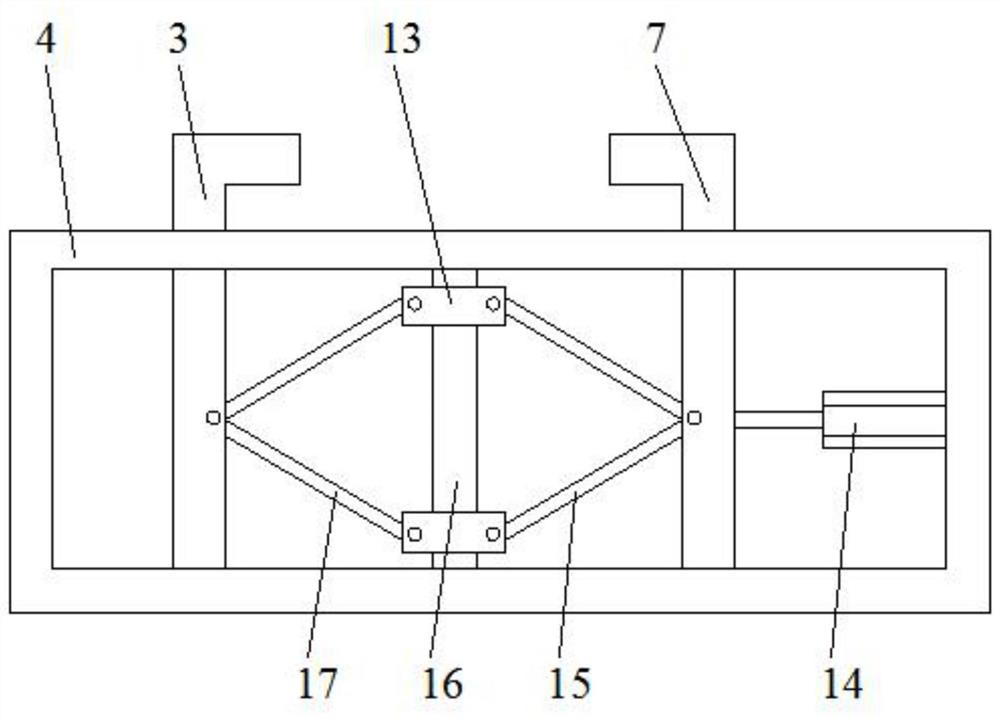

[0024] Reference Figure 1-3 , A light box installation structure for exhibition hall design, comprising a light box 1, a box body 4 and a fixing block 2. The box body 4 is slidably connected to one side of the light box 1, and the box body 4 is arranged parallel to the light box 1, and the top of the box body 4 is welded with The box body 5 is provided with a lifting mechanism for lifting the light box 1 inside the box body 5, and the two ends of the box body 4 away from the light box 1 are slidably connected with a first L-shaped rod 3 and a second L-shaped rod 7. The L-shaped rod 3 and the second L-shaped rod 7 are arranged symmetrically, and the lateral sides of the first L-shaped rod 3 and the second L-shaped rod 7 are arranged parallel to the box body 4, and the fixed block 2 is located at the first L-shaped rod 3 and the second L-shaped rod 3 Between the opposite ends of the horizontal side of the L-shaped rod 7 and the side of the fixed block 2 close to the first L-shap...

Embodiment 2

[0028] Reference Figure 4 The difference between this embodiment and Embodiment 1 is that the moving mechanism includes a first pulley 18, a second pulley 21 and a belt 20, and the first pulley 18, the second pulley 21 and the belt 20 are all rotatably connected to the inside of the box body 4. , The belt 20 is sleeved on the first pulley 18 and the second pulley 21, and the first pulley 18 and the second pulley 21 are arranged in parallel, the upper horizontal edge of the belt 20 passes through the vertical edge of the first L-shaped rod 3 and is bonded to the first Inside the vertical side of the L-shaped bar 3, and the lower horizontal side of the belt 20 passes through the vertical side of the first L-shaped bar 3 and is slidably connected to the inside of the vertical side of the first L-shaped bar 3, and the upper horizontal side of the belt 20 passes through the second L-shaped bar 7 The vertical edge is slidably connected to the inside of the vertical edge of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com