An anti-vibration hammer convenient for installation for overhead wires

A convenient installation and anti-vibration hammer technology, which is applied in the direction of mechanical vibration attenuation devices, etc., can solve the problems of damage to the insulation layer displacement risk, and the anti-vibration hammer is not easy to install, etc., to achieve the effect of convenient installation and removal operation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

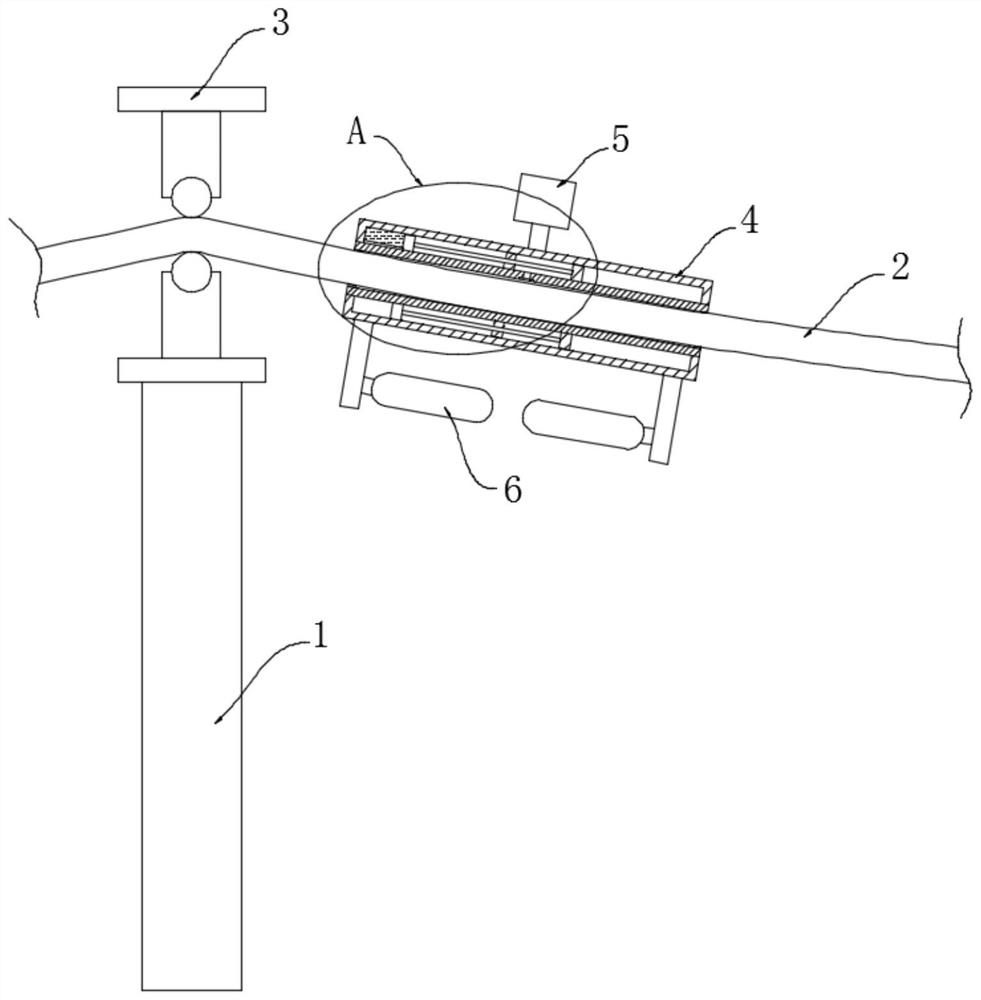

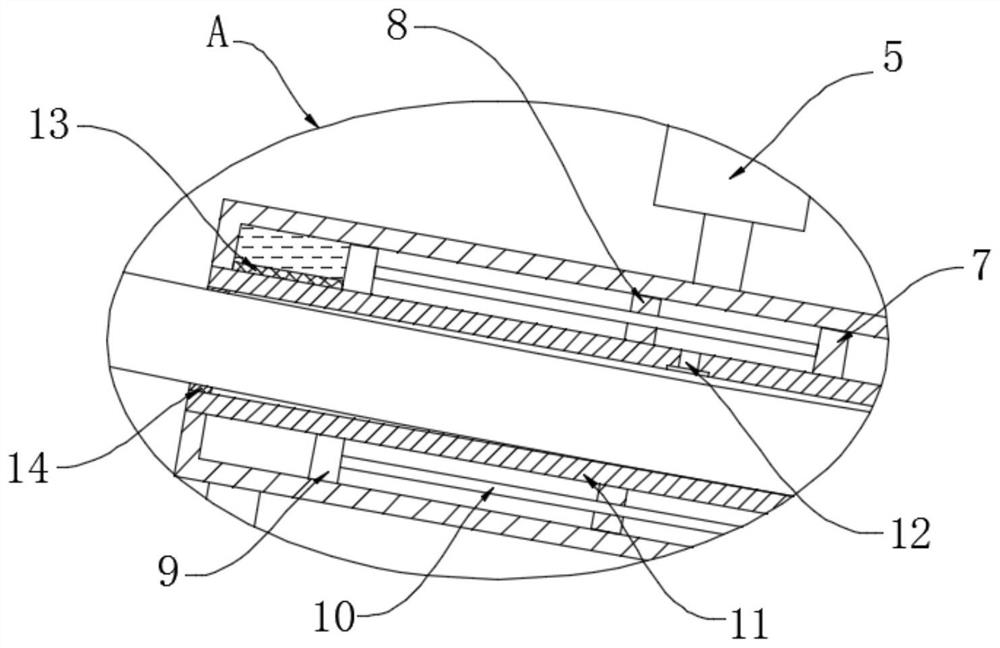

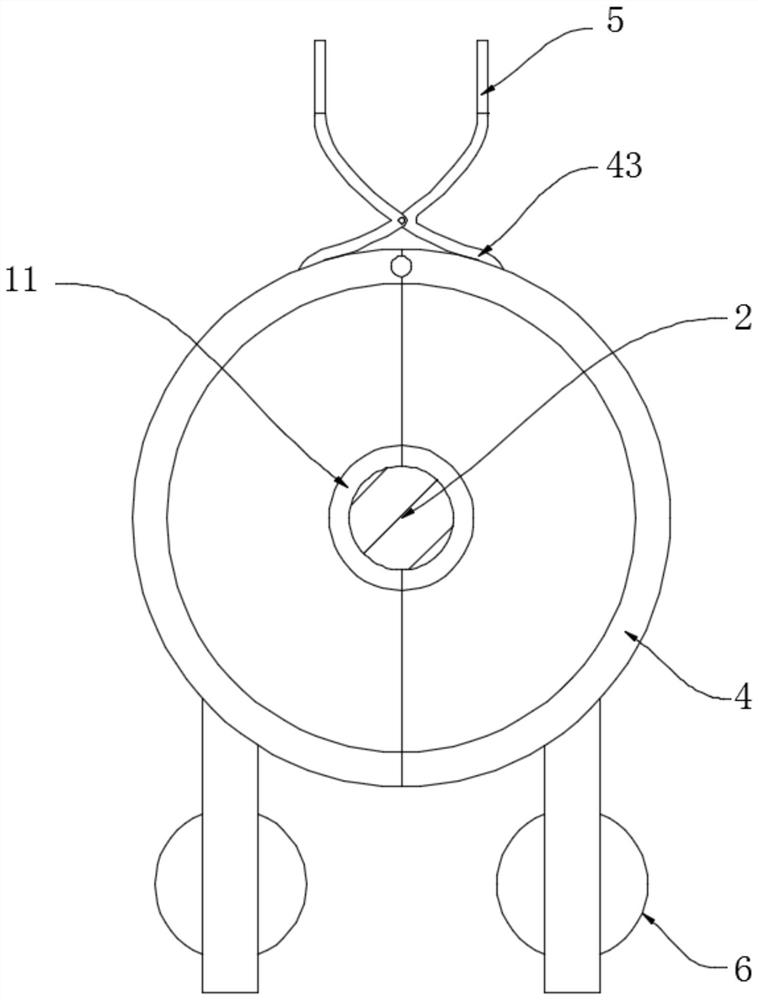

[0021] refer to Figure 1-3 , an anti-vibration hammer for overhead wires that is easy to install, including a pole 1, a wire 2 and a connecting bracket 3, the part of the wire close to the connecting bracket 3 is covered with a fixing ring 4 with a sleeve structure, and the bottom of the fixing ring 4 passes through multiple A fixed rod is fixedly connected with a plurality of hammer bodies 6, and the fixed ring 4 is made up of two half-ring parts 41, and the junction of the two half-ring parts 41 is connected by torsion spring 42 rotation, and each half-ring part 41 is all fixedly connected with A turntable 43, the middle part of the two turntables 43 is connected by pin shaft rotation and is all fixedly connected with the hand press plate 5 at the end;

[0022] Each half-ring part 41 is fixedly connected with a first half-ring plate 7, and the two sides of the first half-ring plate 7 located in the half-ring part 41 are respectively slidably connected with a second half-rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com