Precise hole sowing machine for grass seeds

A hole sowing machine, precision technology, applied in the direction of hole sowing seeder, planter parts, spaced quantitative sowing machinery, etc., can solve the problems of unable to take root and germinate, destroy seeds, and the sowing amount cannot be adjusted, etc., to solve the problem of not being able to take root and germinate , simple structure, and the effect of improving the quality of grass seed sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

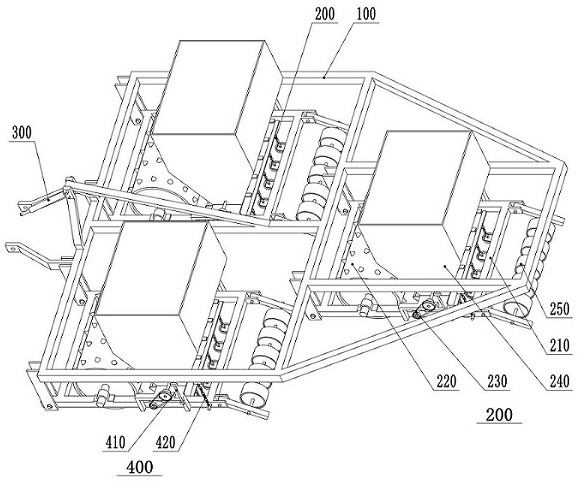

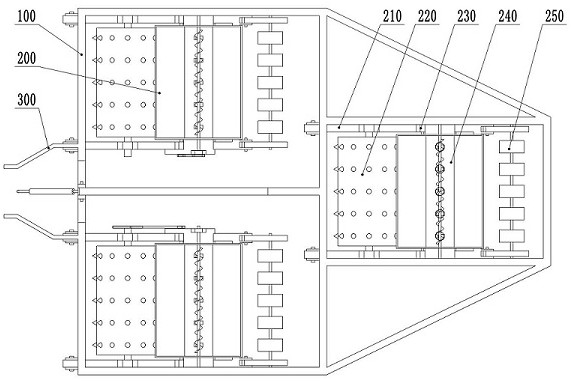

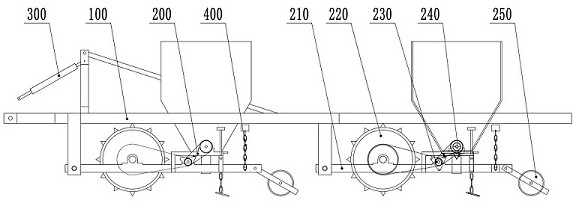

[0032] refer to figure 1 , the embodiment provides a grass seed precision hole sowing machine, including a frame 100 and a plurality of hole sowing devices 200 installed on the frame, a traction mechanism 300 is provided at the front end of the frame; Hole-opening device 220, transmission device 230, seeding device 240 and soil-covering suppressing device 250; Hole-opening device 220 is positioned at the front of fixed frame 210, and comprises the roller 222 that is provided with hole-opening tooth 221, and roller 222 is installed on fixed frame by roller 223 On 210, a driving wheel 231 is provided on one side of the roller 223; the seeding device 240 is located in the middle of the fixed frame 210, including a seed box 241, and the bottom of the seed box 241 is provided with a stirring shaft 242 and a plurality of seed discharge ports 243, and the stirring shaft 242 is located in the row Above the seed port 243, the stirring shaft 242 side is provided with a driven wheel 232,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com