Fermented material for agaricus bisporus production and preparation method of fermented material

A technology for fermentation material and Agaricus bisporus, which is applied in the directions of botanical equipment and methods, application, mushroom cultivation, etc., can solve problems such as peculiar smell, and achieve the effects of increasing yield, avoiding peculiar smell, and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Example 1, a fermented material for the production of Agaricus bisporus, prepared from raw materials with the following weight ratios,

[0034] Wheat straw 65, soybean meal 6, distiller's grain 7, Pleurotus eryngii culture medium waste material 6, ammonium sulfate 0.5, gypsum 5.0, wherein the moisture content in the Pleurotus eryngii culture medium waste material is ≤ 55%, and the ash content is ≤ 13%;

[0035] The moisture content in the ammonium sulfate is ≤0.15%, and the nitrogen content is ≥21%;

[0036] The moisture content in the gypsum is ≤26%.

[0037] The preparation method of the fermented material for the production of Agaricus bisporus is as follows:

[0038] (1) Material: take wheat straw according to the raw material ratio and perform pre-wetting treatment to form base material;

[0039] Take soybean meal, pleurotus eryngii culture medium waste, and distiller's grains according to the raw material ratio and mix them to form the first auxiliary material;

[0040] Take ...

Example Embodiment

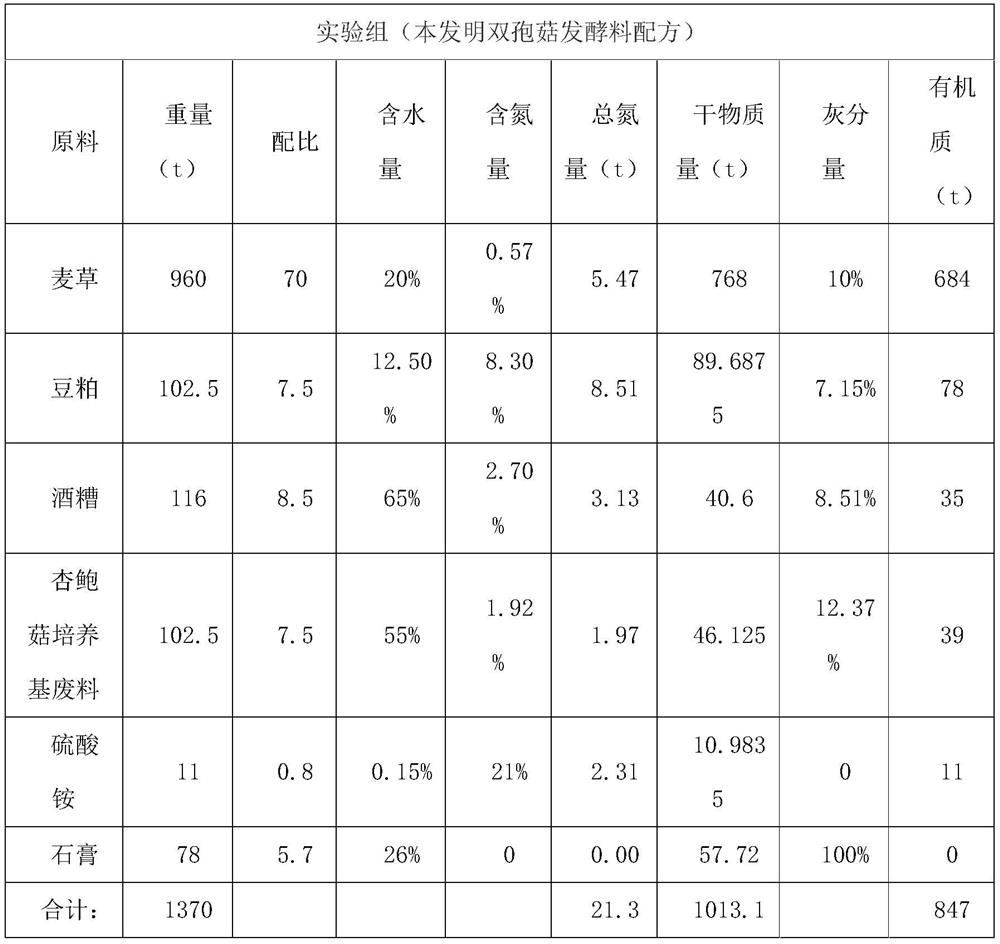

[0045] Example 2, a fermented material for the production of Agaricus bisporus, prepared from the following raw materials in weight ratio: wheat straw 70, soybean meal 7.5, distiller’s grain 8.5, pleurotus eryngii culture medium waste 7.5, ammonium sulfate 0.8, and gypsum 5.7.

[0046] The preparation method of the fermented material for the production of Agaricus bisporus is as follows:

[0047] (1) Material: take wheat straw according to the raw material ratio and perform pre-wetting treatment to form base material;

[0048] Take soybean meal, pleurotus eryngii culture medium waste, and distiller's grains according to the raw material ratio and mix them to form the first auxiliary material;

[0049] Take ammonium sulfate and gypsum according to the raw material ratio and mix them uniformly to form the second auxiliary material;

[0050] (2) Making auxiliary materials: Sprinkle the second auxiliary material evenly on the first auxiliary material, and continuously turn the pile until it...

Example Embodiment

[0054] Example 3, a fermented material for the production of Agaricus bisporus, prepared from the following raw materials in weight ratio: wheat straw 80, soybean meal 9, distiller's grain 10, pleurotus eryngii medium waste 9, ammonium sulfate 1, gypsum 6.5.

[0055] The preparation method of the fermented material for the production of Agaricus bisporus is as follows:

[0056] (1) Material: take wheat straw according to the raw material ratio and perform pre-wetting treatment to form base material;

[0057] Take soybean meal, pleurotus eryngii culture medium waste, and distiller's grains according to the raw material ratio and mix them to form the first auxiliary material;

[0058] Take ammonium sulfate and gypsum according to the raw material ratio and mix them uniformly to form the second auxiliary material;

[0059] (2) Making auxiliary materials: Sprinkle the second auxiliary material evenly on the first auxiliary material, and continuously turn the pile until it is evenly mixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com