Method for carrying out shot blasting treatment on workpiece

A technology of workpieces and movable parts, which is applied in the field of shot blasting treatment of workpieces, can solve the problem of high equipment cost, achieve the effect of reducing production cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

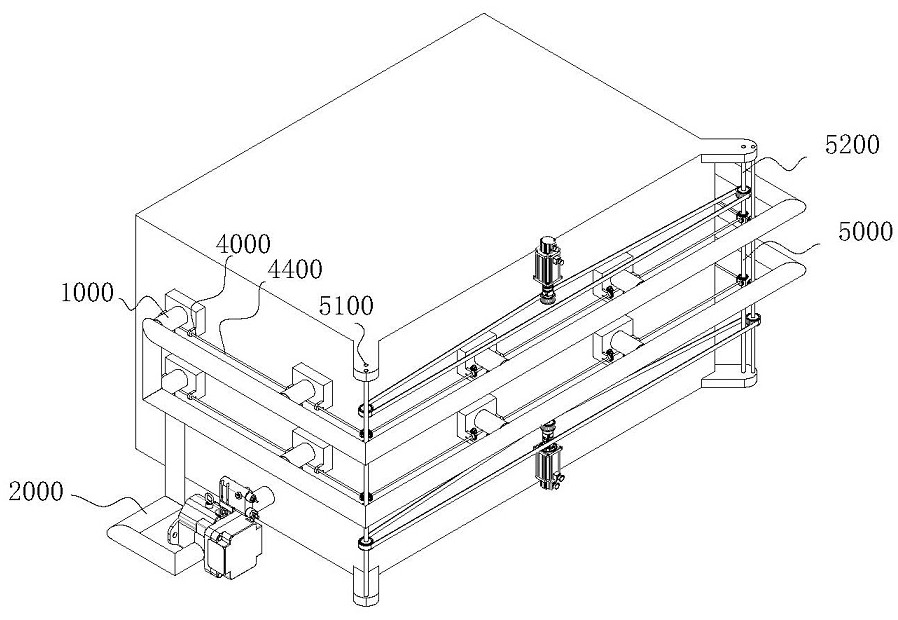

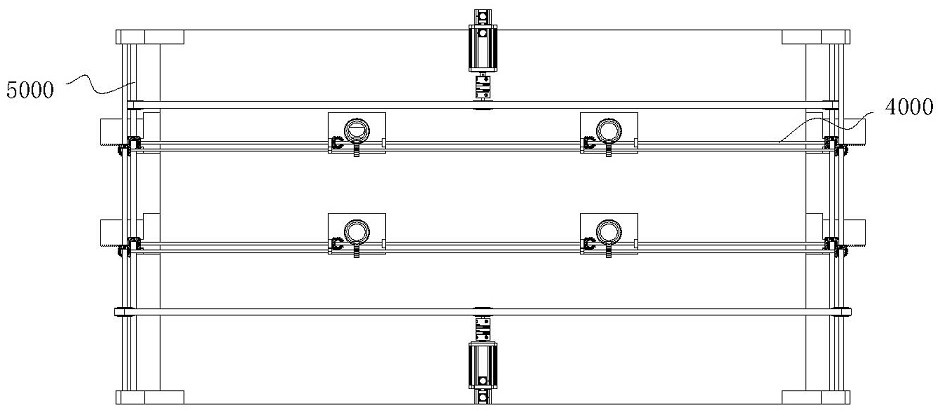

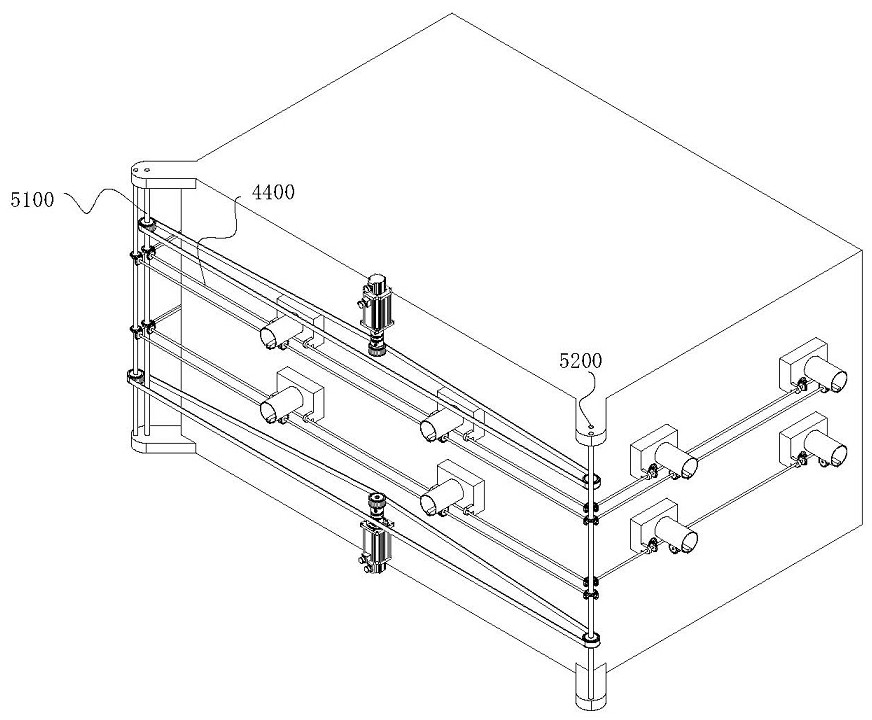

[0030] Such as Figure 1-8 As shown, a shot blasting treatment equipment includes a box body, and the box body is provided with a hanging mechanism for hanging workpieces and a shot blasting mechanism for surface treatment of workpieces. Each shot blasting unit 1000 is composed of a shot blasting material circulation unit 2000 for recycling and transporting shot blasting materials. The shot blasting unit 1000 includes a shot blasting nozzle 1100, which is arranged along the thickness direction of the box wall. The shot blasting nozzle The end of the 1100 extending t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap