Industrial stacking machine for carrying box bodies

An industrial and palletizing technology, applied in the field of industrial handling, can solve problems such as box position deviation, and achieve the effect of reducing the difficulty of judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

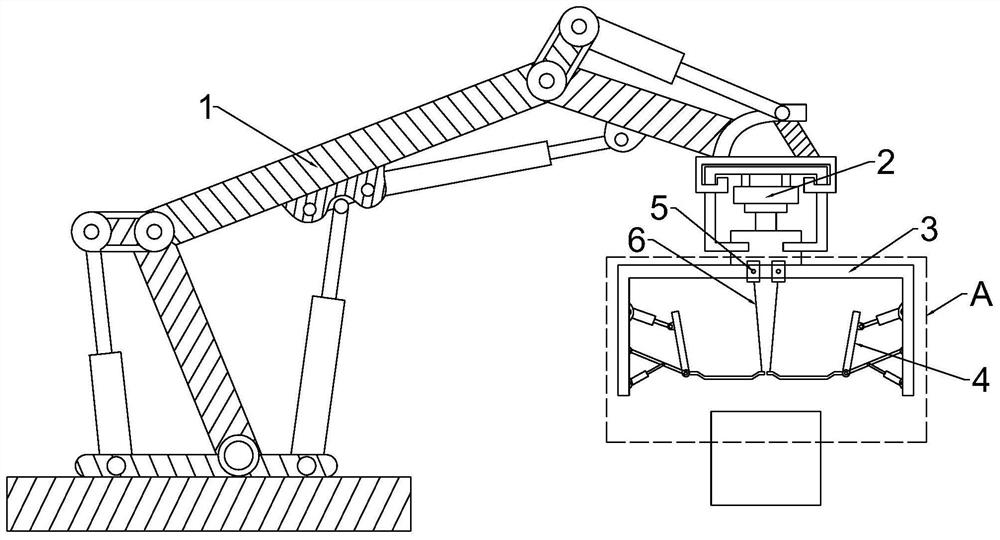

[0025] Such as figure 1 , an industrial palletizing machine for box handling, including a mechanical arm 1, a motor 2, a support frame 3, a clamping device 4, a barrel 5, a traction rope 6 and a control system.

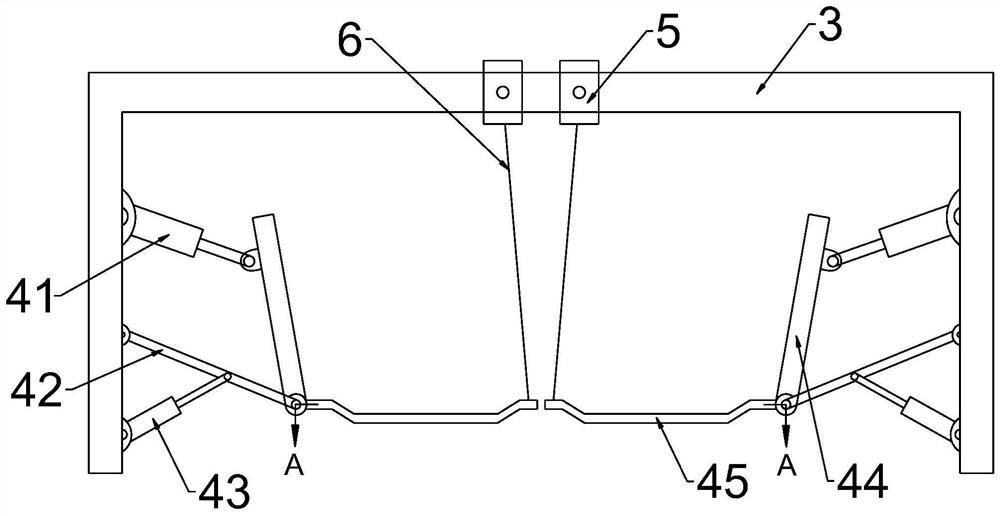

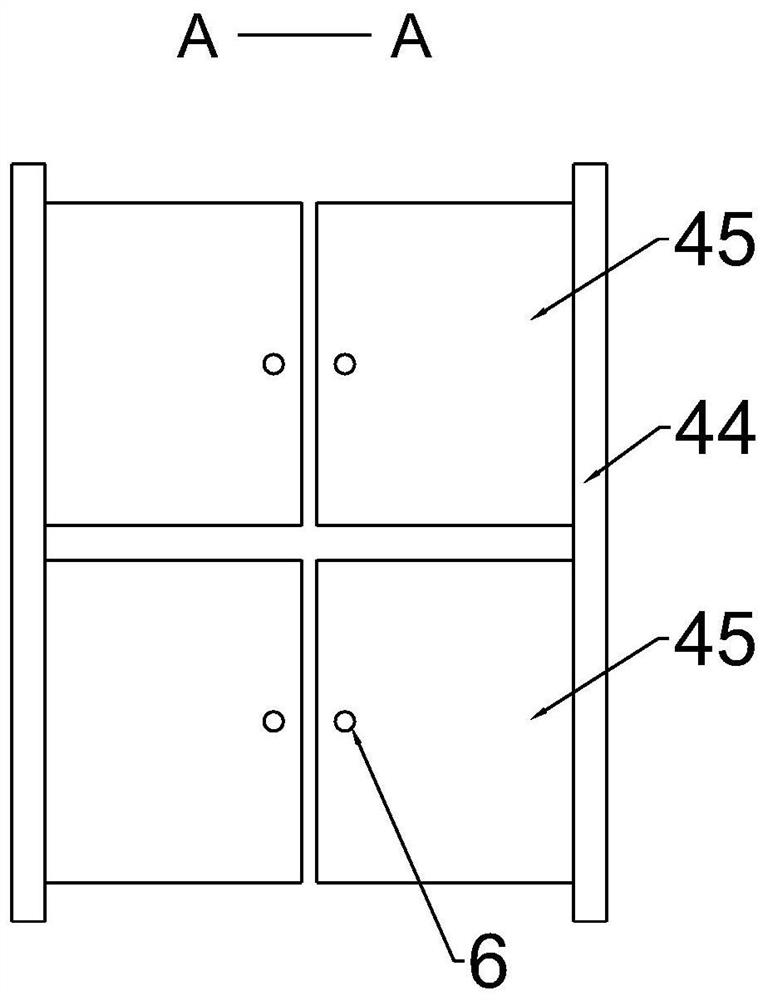

[0026] Such as figure 2 , 3 , the motor 2 is installed on one end of the mechanical arm 1; the support frame 3 is arranged on the top of the mechanical arm 1, and the output shaft of the motor 2 is connected with the support frame 3; the clamping device 4 has Two groups, and these two groups of clamping devices 4 are symmetrically arranged on the side walls on both sides inside the support frame 3. The clamping devices 4 include No. 1 hydraulic rod 41, connecting rod 42, No. 2 hydraulic rod 43, pressure Plate 44, positioning plate 45 and angle sensor, one end of the No. 1 hydraulic rod 41 is hinged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com