Automatic bearing connecting material conveying reversing device

A reversing device and automatic technology, applied in the direction of transportation, packaging, conveyors, etc., can solve problems affecting production efficiency, damage, vertical guide plate and chain sticking, etc., to avoid unsmooth cooperation, improve wear resistance, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiment is illustrated below in conjunction with accompanying drawing:

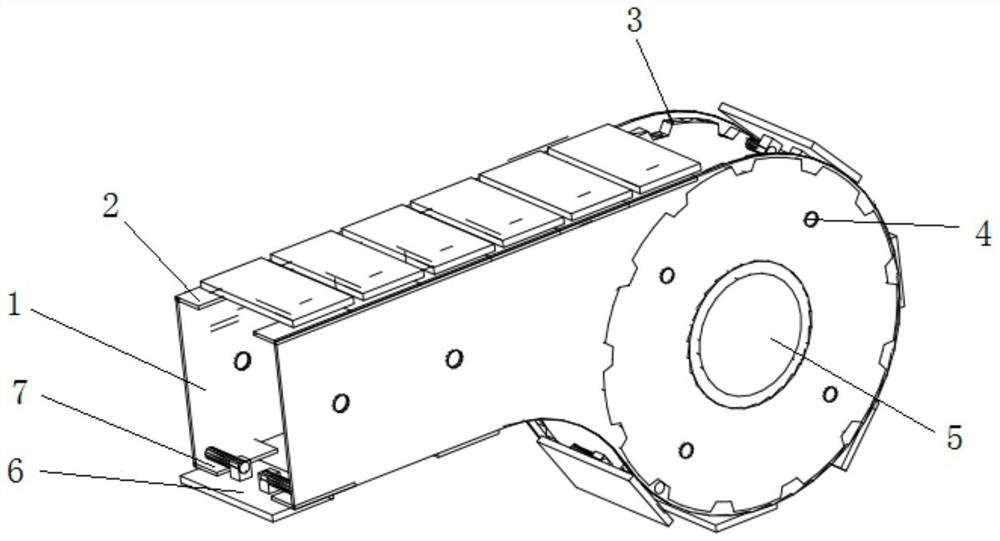

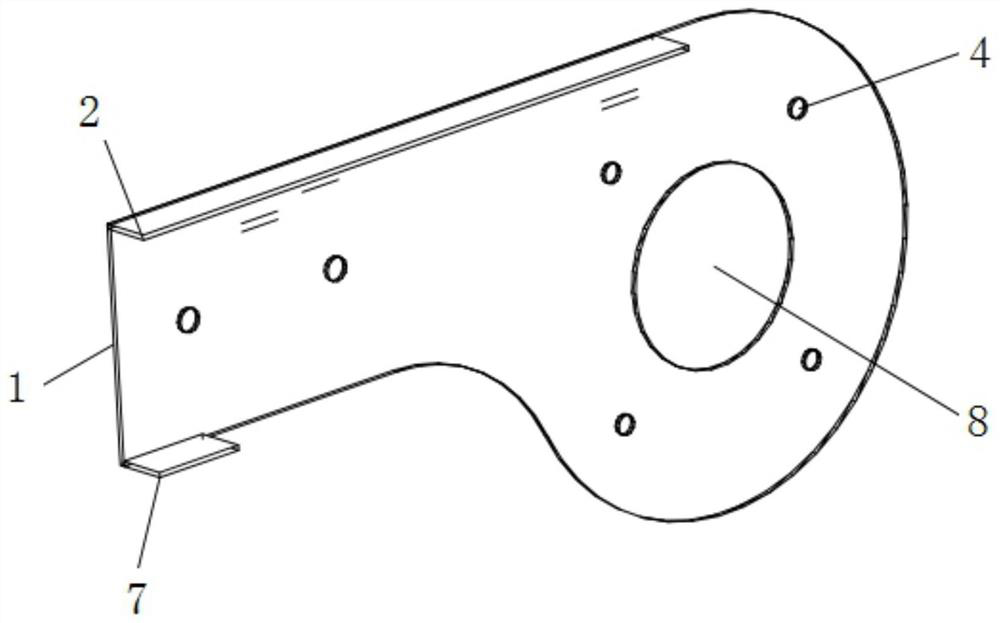

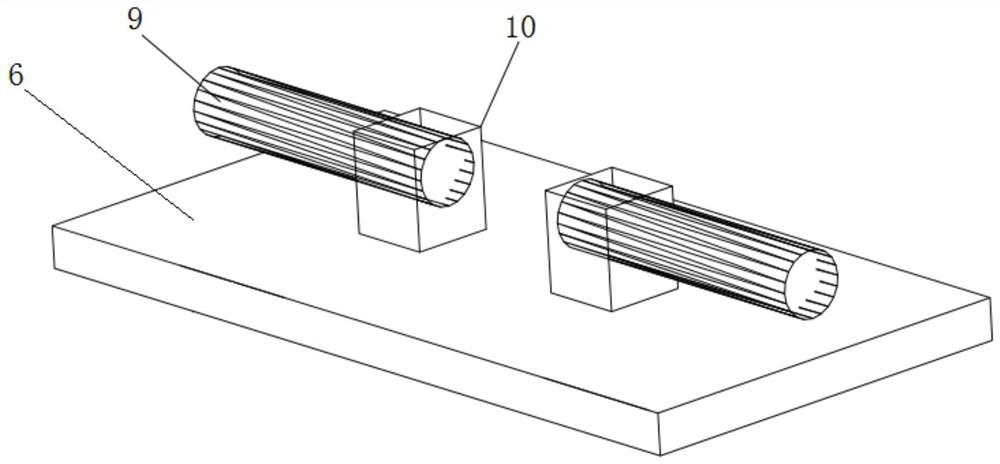

[0013] The present invention is a kind of bearing automatic connection line transport material reversing device, comprises: reversing guide plate 1, transmission gear 3, transmission shaft 5, movable chain plate 6, described reversing guide plate 1 is made up of a pair of corresponding reversing guide plate 1 Composition, the reversing guide plate 1 is provided with an upper conveying guide rail 2, a lower conveying guide rail 7, a mounting hole 4 and a drive shaft mounting hole 8; the movable chain plate 6 is provided with a support block 10, and the support block 10 is equipped with There is a conveying rod 9, and the two ends of the transmission shaft 5 are respectively equipped with a reversing guide plate 1 and a transmission gear 3, and the described conveying rod 9 is meshed with the transmission gear 3.

[0014] The reversing guide plate 1, the upper conveying guide rail 2, the lower con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com