Glass transferring system for glass bending furnace

A glass transfer and hot bending furnace technology, applied in the field of heat treatment, can solve the problems of automatic reversing transmission of glass plates, easy downward bending of the conveyor belt, and unstable placement of glass plates, etc., achieving low cost, reduced space occupation, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The embodiments are described below with reference to the accompanying drawings. The embodiments shown below do not limit the invention content described in the claims. required for the solution.

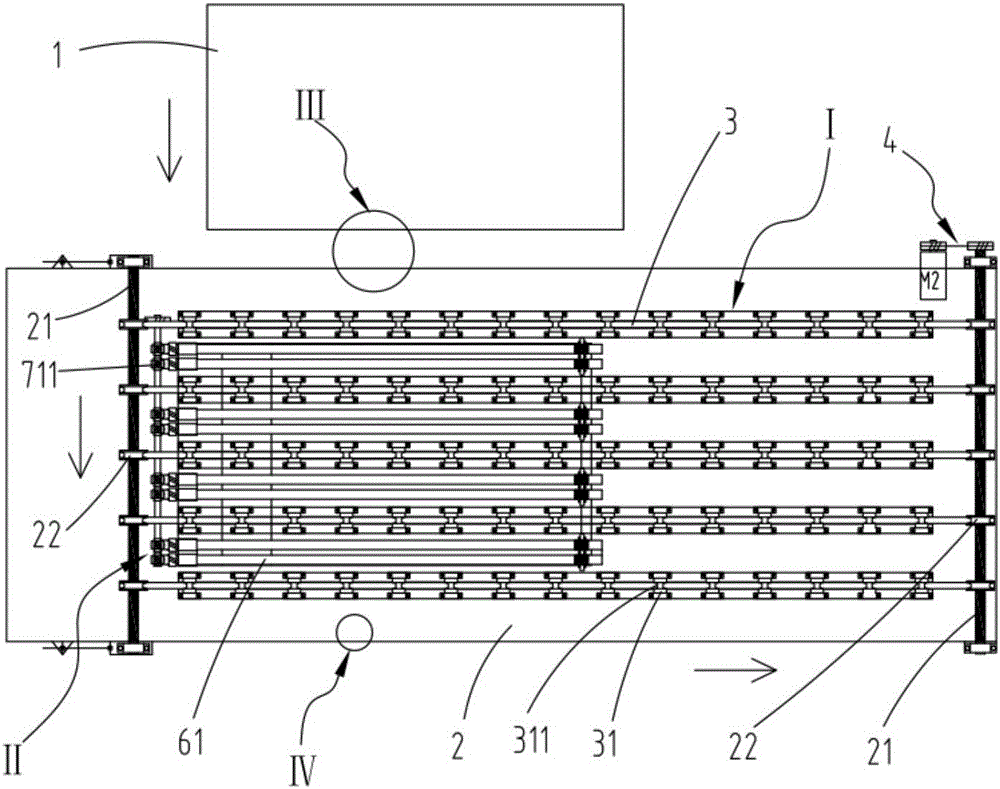

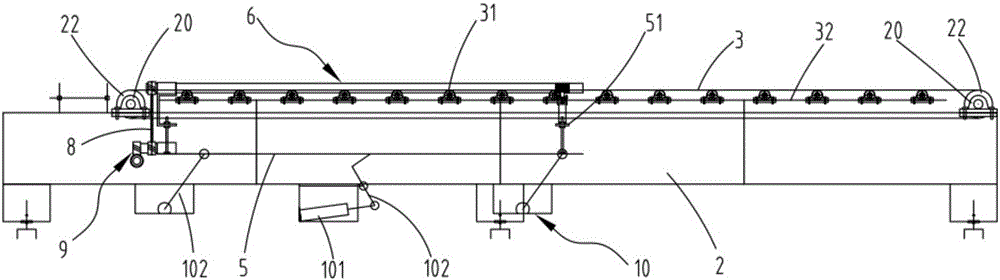

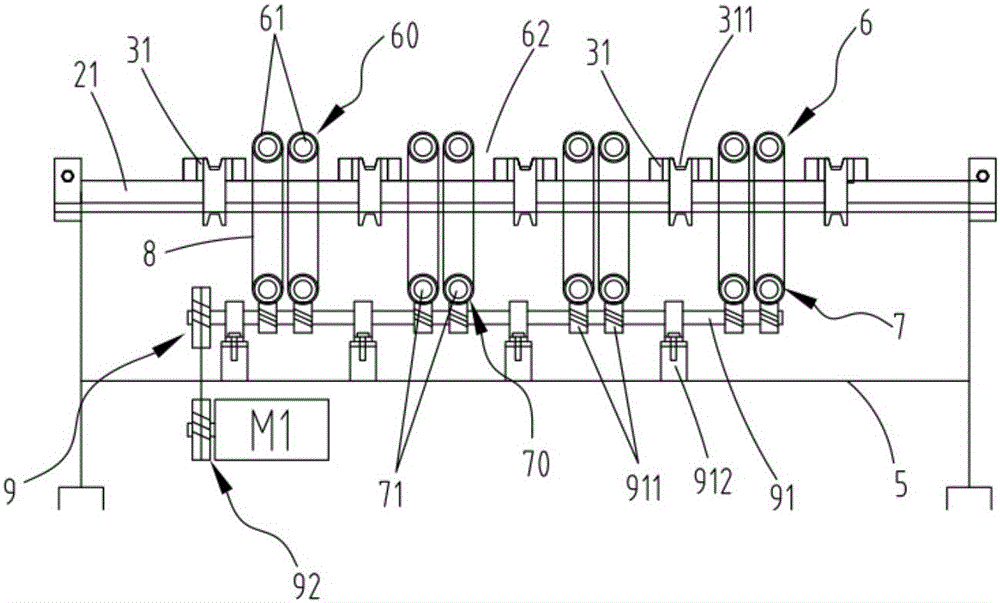

[0042] figure 1 It is a schematic diagram of a preferred embodiment of a glass transfer system for a glass bending furnace according to the present invention, and the transfer system includes:

[0043] Vertical conveying mechanism I, used to receive the glass 1 conveyed from the glass bending furnace and convey the glass 1 along the original path;

[0044] Horizontal conveying mechanism II is used to receive the glass 1 conveyed from the longitudinal conveying mechanism I and convey the glass 1 along the direction perpendicular to the original path to the next process for processing;

[0045] The first detection module III is used to detect the moving distance of the glass 1 transported from the glass 1 bending furnace, and the longitudinal transmission mechanism I starts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com