Bottom liquid drainage device

A discharge device and bottom liquid technology, applied in liquid separation, liquid separation auxiliary equipment, dispersed particle separation, etc., can solve the problems of large discrete structure, inconvenient installation and debugging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

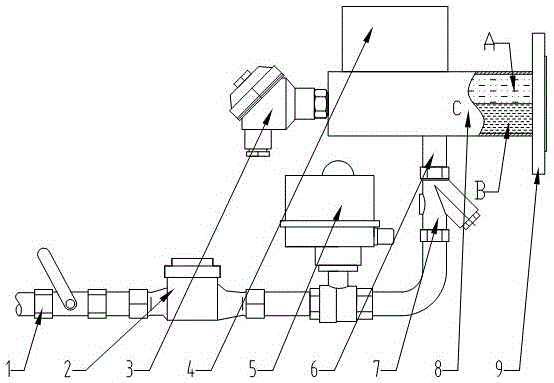

[0009] Such as figure 1 As shown, the right end of the pipe joint (9) is connected to the bottom liquid outlet pipe of the storage tank, and the left end is connected to the measuring tube (8), which is responsible for the pipe connection and the fixing of the entire device. In the measuring tube (8), the upper part is liquid A with low density, the bottom is liquid B with high density, and the two-phase liquid interface C; the bottom of measuring tube (8) is connected with discharge pipe (6), measuring tube (8) The interface measurement device (3) and the electric control box (4) are also installed on it; the discharge pipe (6) has a filter (7), an automatic control valve (5), a metering detection device (2) and a manual valve ( 1).

[0010] There is a signal remote transmission communication interface in the electric control box (4), which can communicate with the central control equipment in a network. When working, the control circuit processes various working signals of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com