Polarized capacitor aluminum case multi-station belt material continuous deep-drawing technique and continuous tandem die

An electrolytic capacitor, multi-station technology, applied in capacitor shell/package, capacitor, capacitor manufacturing and other directions, can solve the problem of the need to improve the punching efficiency, meet the production requirements and low cost, simple and practical structure, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

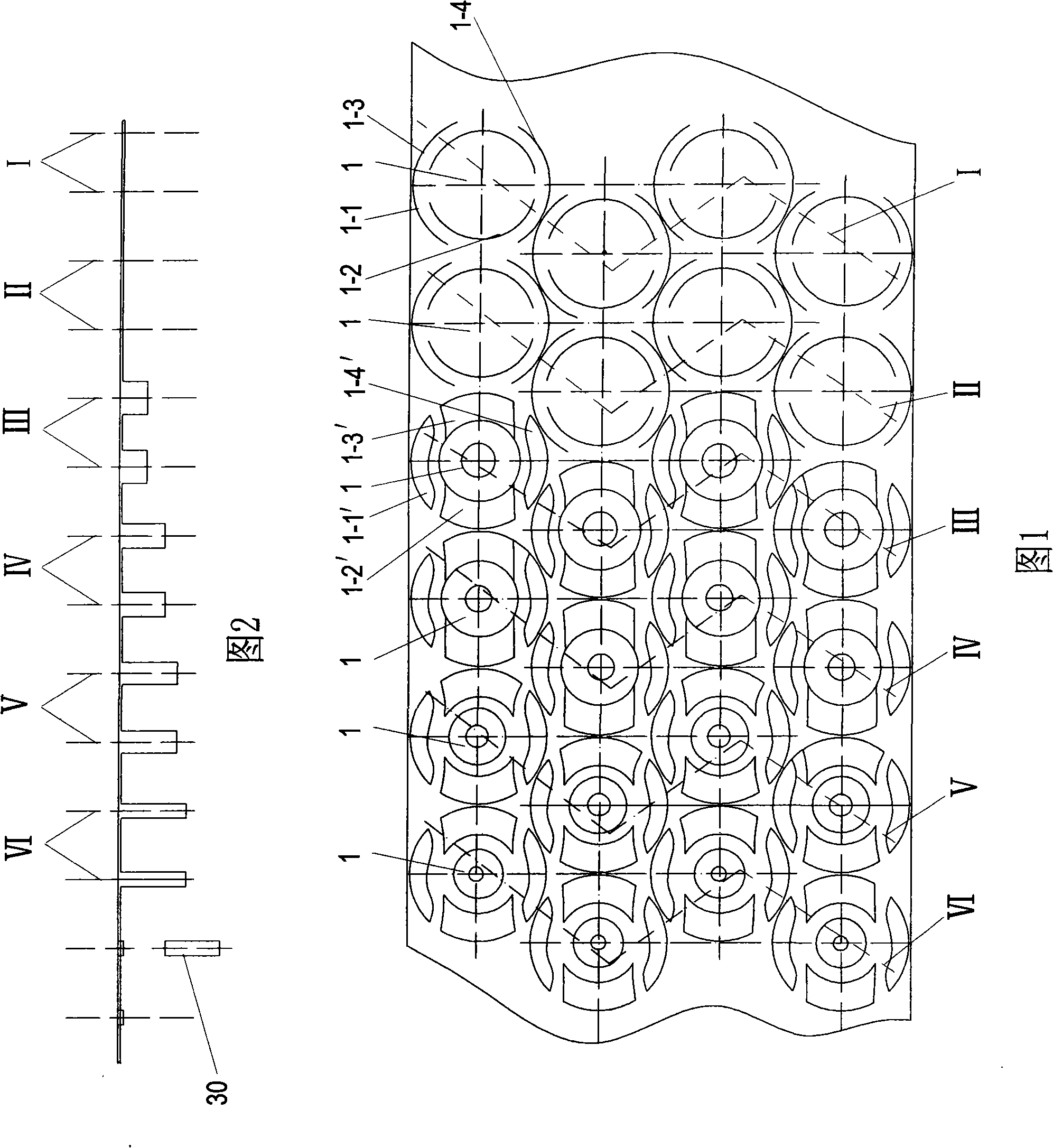

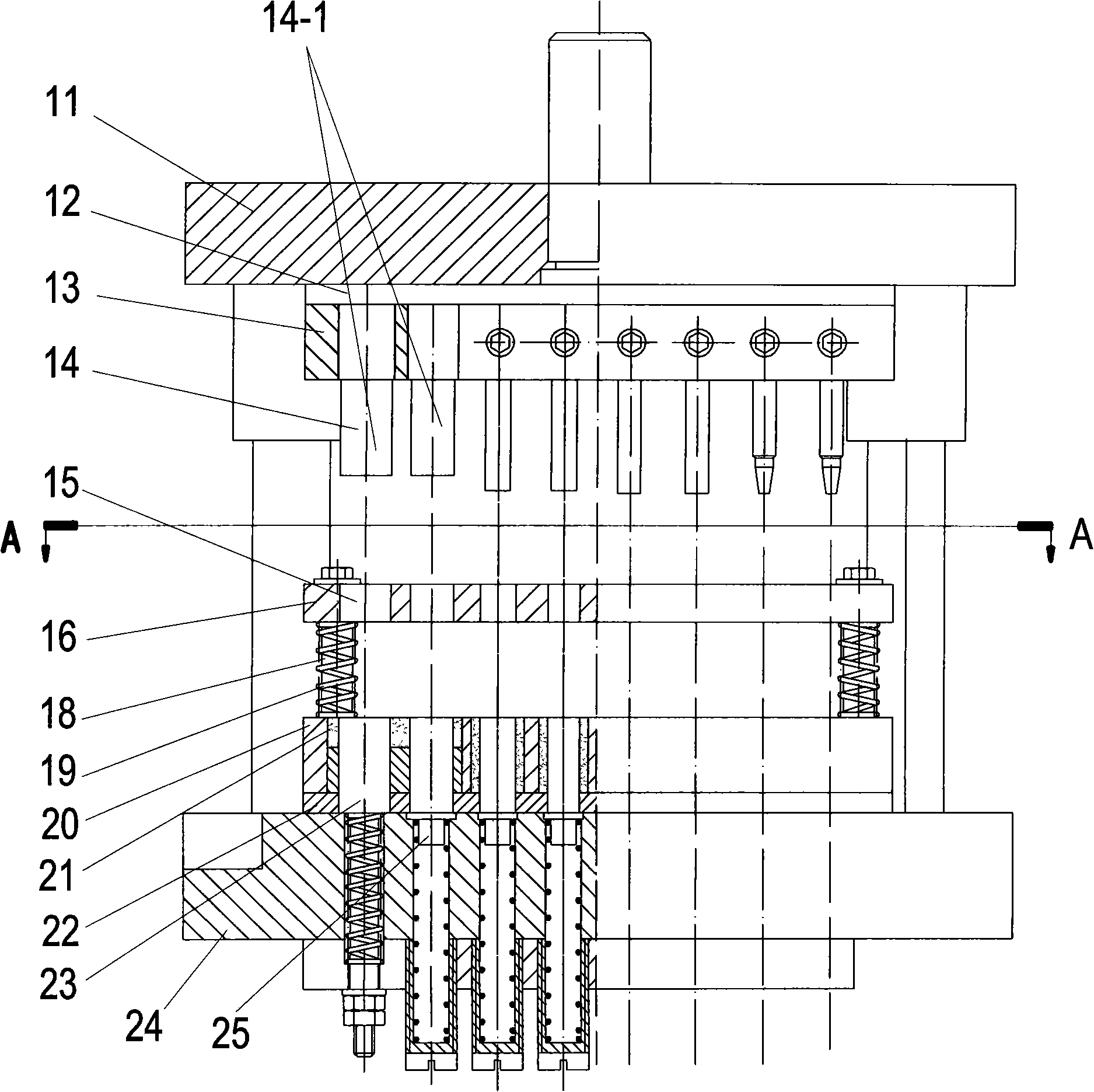

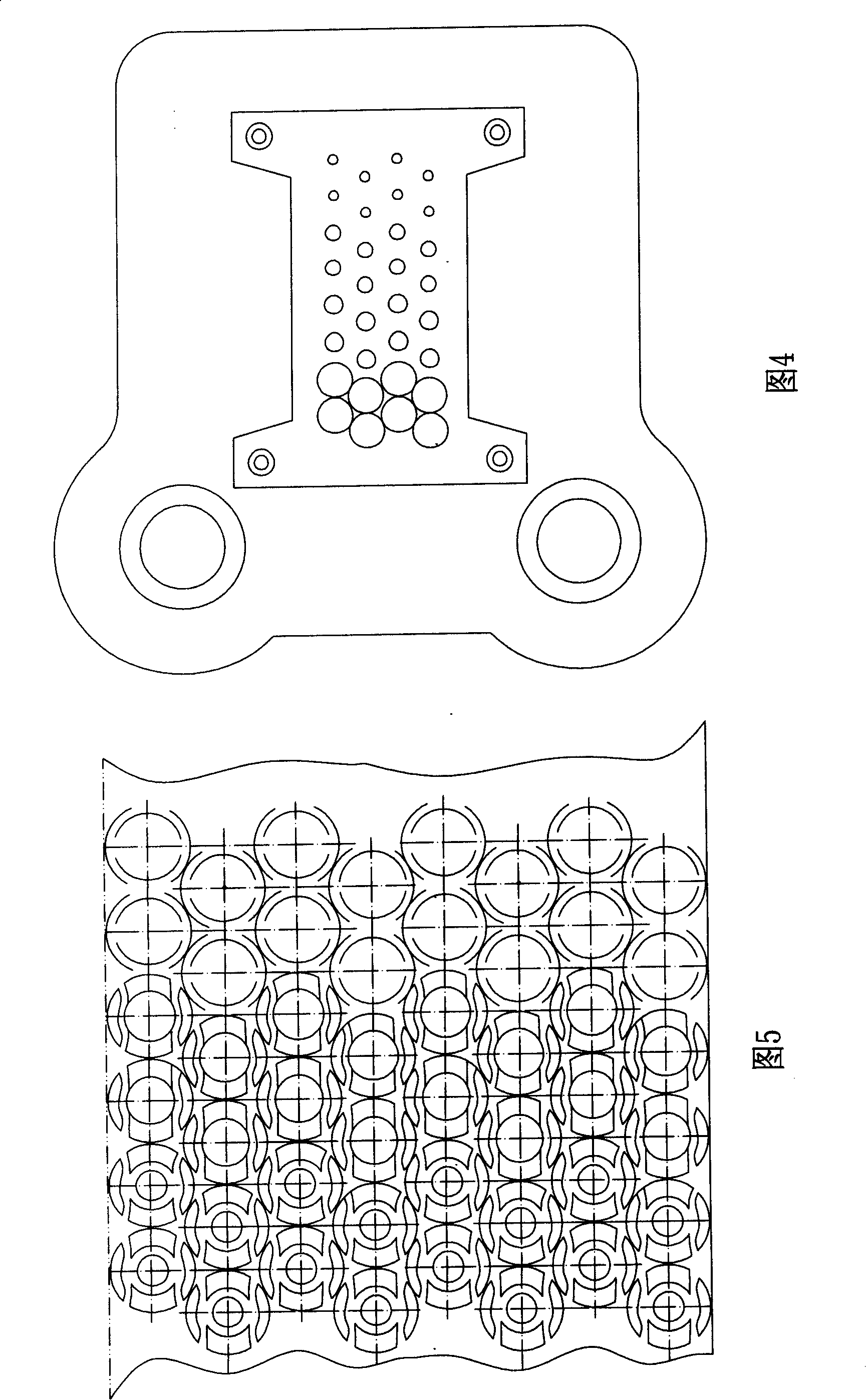

[0022] Electrolytic capacitor aluminum shell multi-station continuous drawing process with material, the steps are:

[0023] 1) According to the number of horizontal rows of capacitor aluminum casings (generally 3-20 rows), carry out the layout of the aluminum casing material, and determine the required strip width; this is because the flat aluminum material is stamped and drawn It is a three-dimensional cylindrical aluminum shell, which is a process in which the diameter gradually decreases and the height gradually increases; therefore, the area of the plane aluminum material used is larger (and thicker) than the projected area of the aluminum shell, which can be calculated by empirical formula Sure.

[0024] 2) Punch out contour cuts for each row of aluminum shell materials on the strip, each contour cut consists of 2-6 discontinuous curved fractures, and part of the strip surrounded by each contour cut passes through the subsequent steps Punched into an aluminum shell,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com