Three-dimensional weaving method of lining cloth

An interlining and three-dimensional technology, applied in the field of weaving, can solve problems such as poor human comfort, increased energy consumption, and poor air permeability, and achieve the effects of reducing energy consumption and pollution, good air permeability, and improving human comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

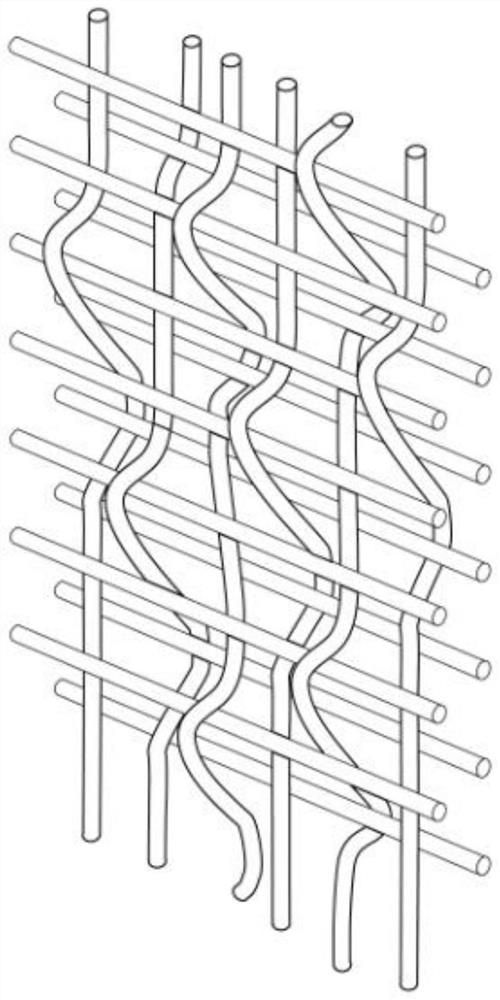

Embodiment 1

[0081] Vertical lines are warp threads, horizontal lines are weft threads, five warp threads in the warp thread group, seven weft threads in the front weft thread group, and seven weft threads in the rear weft thread group form a weaving cycle. The leftmost meridian is set as the first meridian, followed by the second meridian, the third meridian, the fourth meridian, and the fifth meridian respectively to the right; Threads, in turn, are the second thread of the front weft group, the third thread of the front weft group, the fourth thread of the front weft group, the fifth thread of the front weft group, the sixth thread of the front weft group, The seventh line of the front weft group; the top weft of the back weft group is the first line of the back weft group, and the next ones are the second line of the back weft group, the third line of the back weft group, and the back row The fourth thread of the weft group, the fifth thread of the back weft group, the sixth thread of ...

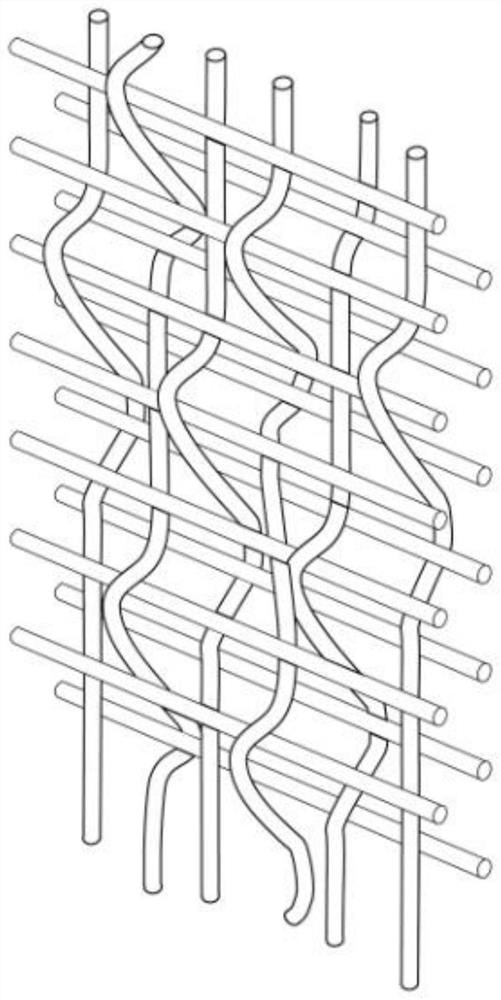

Embodiment 2

[0088] Vertical lines are warp threads, horizontal lines are weft threads, five warp threads in the warp thread group, seven weft threads in the front weft thread group, and seven weft threads in the rear weft thread group form a weaving cycle. The leftmost meridian is set as the first meridian, followed by the second meridian, the third meridian, the fourth meridian, and the fifth meridian respectively to the right; Threads, in turn, are the second thread of the front weft group, the third thread of the front weft group, the fourth thread of the front weft group, the fifth thread of the front weft group, the sixth thread of the front weft group, The seventh line of the front weft group; the top weft of the back weft group is the first line of the back weft group, and the next ones are the second line of the back weft group, the third line of the back weft group, and the back row The fourth thread of the weft group, the fifth thread of the back weft group, the sixth thread of ...

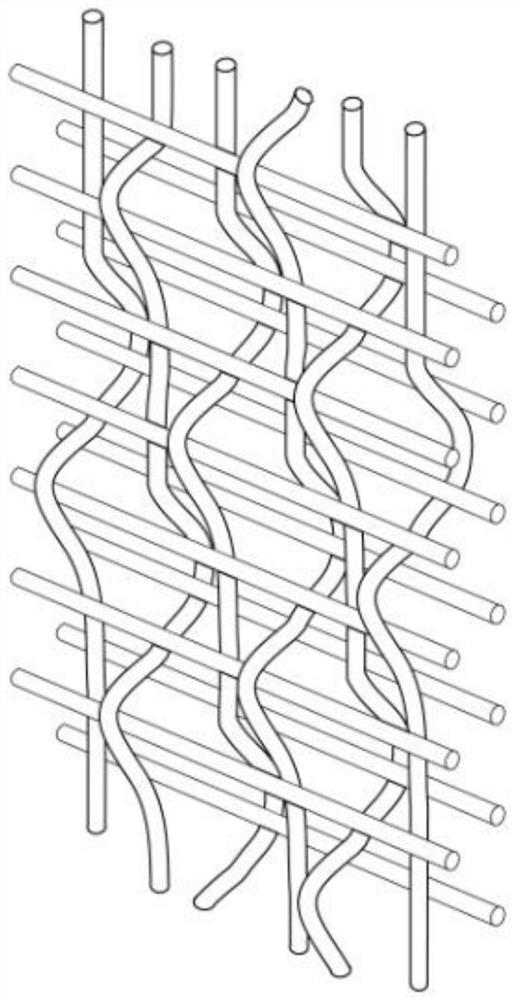

Embodiment 3

[0095] Vertical lines are warp threads, horizontal lines are weft threads, five warp threads in the warp thread group, seven weft threads in the front weft thread group, and seven weft threads in the rear weft thread group form a weaving cycle. The leftmost meridian is set as the first meridian, followed by the second meridian, the third meridian, the fourth meridian, and the fifth meridian respectively to the right; Threads, in turn, are the second thread of the front weft group, the third thread of the front weft group, the fourth thread of the front weft group, the fifth thread of the front weft group, the sixth thread of the front weft group, The seventh line of the front weft group; the top weft of the back weft group is the first line of the back weft group, and the next ones are the second line of the back weft group, the third line of the back weft group, and the back row The fourth thread of the weft group, the fifth thread of the back weft group, the sixth thread of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com