Electronic drum structure with uniform output

An electronic drum and uniform technology, applied in the field of musical instrument manufacturing, can solve the problems of uneven drum rim signal, small drum rim sound, and difficult drum rim pickup methods, and achieve the effect of solving the small drum rim signal and improving the output amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

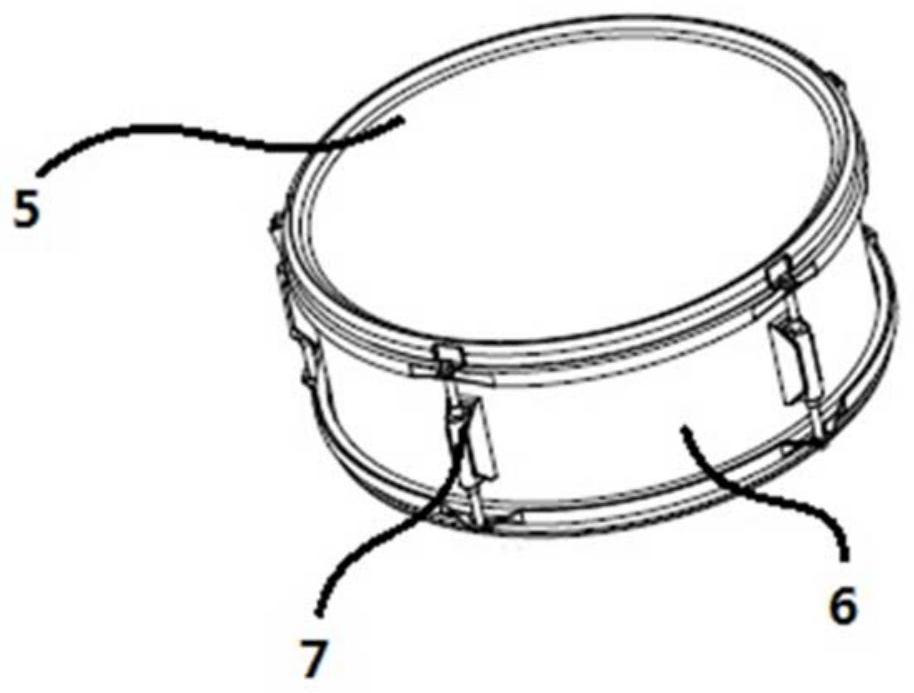

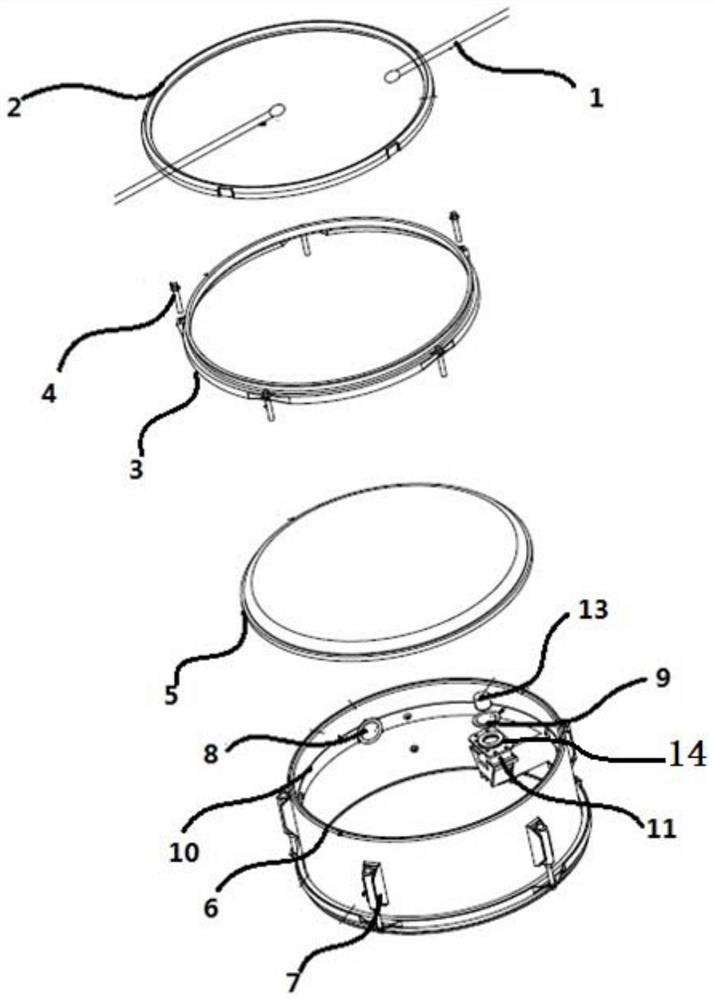

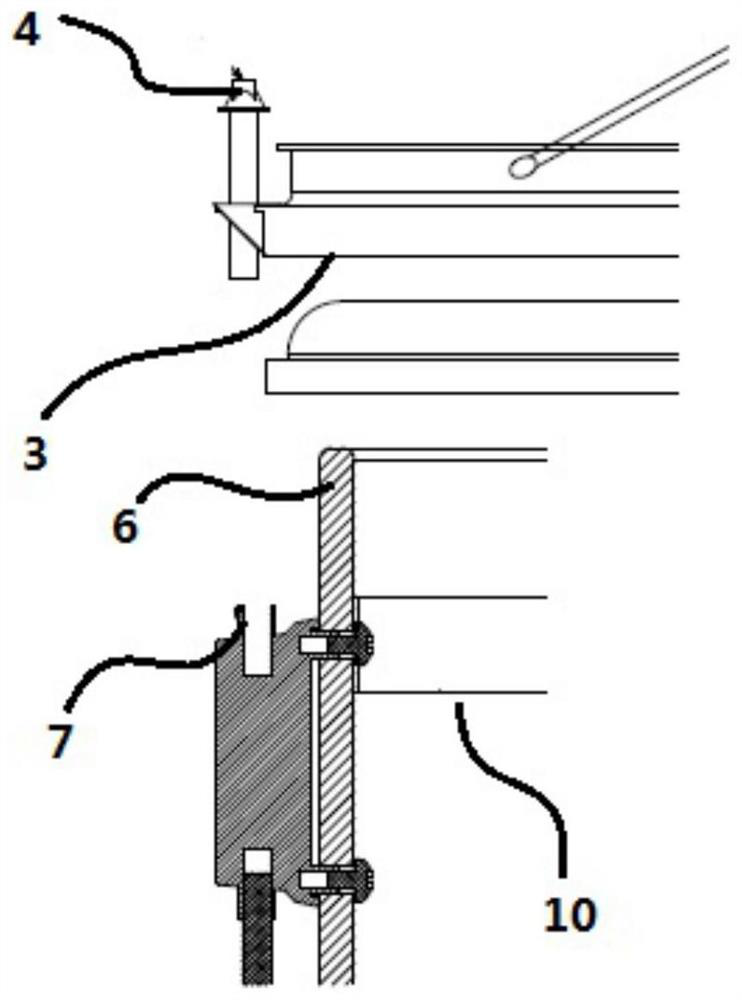

[0019] see figure 1 and figure 2 , which shows an example scheme for the composition of an electronic drum with uniform output given in this example. It can be seen from the figure that the electronic drum is mainly composed of an electronic drum component, a drum surface pickup component, a drum edge pickup component and a signal detection component. .

[0020] Among them, the rim sound pickup component is arranged on the inner wall of the drum barrel in the electronic drum assembly, contacts and cooperates with the inner wall of the drum barrel, and is connected with the signal detection component signal, thereby forming an independent rim sound pickup sensor channel, effectively improving the sound quality of the drum. The output amplitude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com