Control box quick assembly structure of lifting table and lifting table frame

A technology for assembling a structure and a control box, applied in the field of lifting table accessories, can solve the problems of large changes in the structure of the control box, troublesome and laborious replacement of the position of the control box, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

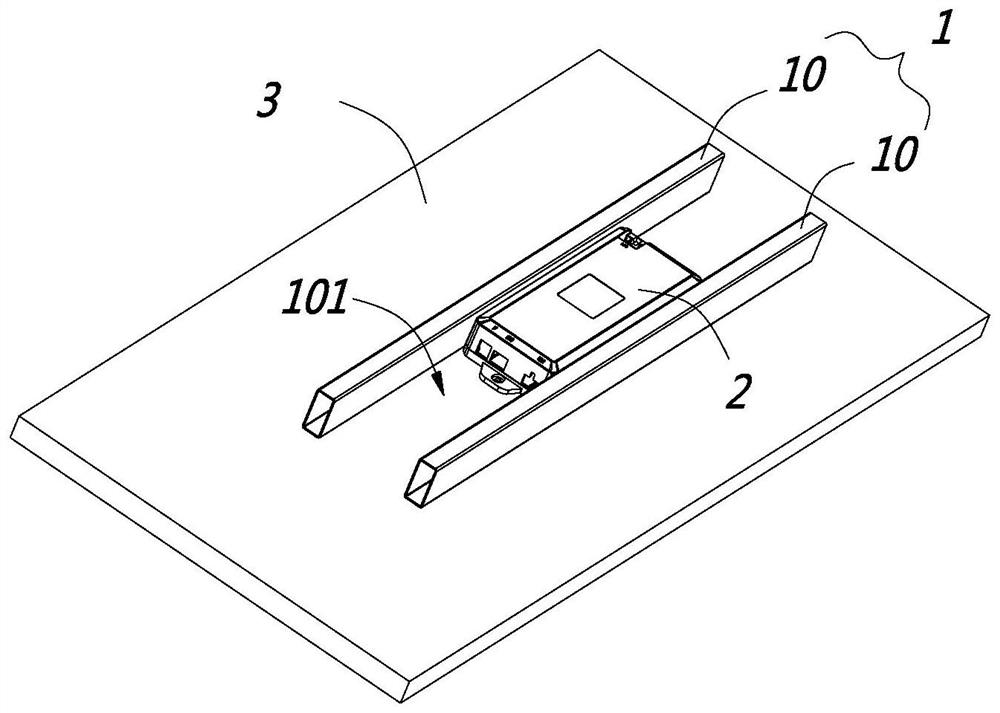

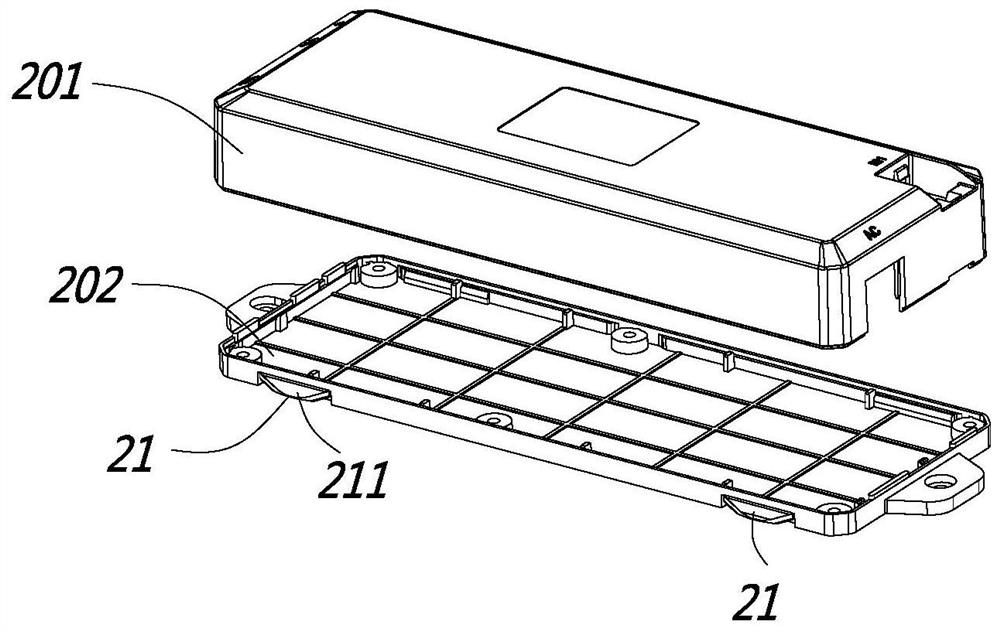

[0033] Such as Figure 1 to Figure 6 As shown, this embodiment shows a quick assembly structure of the lift table control box 2, including a beam 1 and a control box 2, the beam 1 is used to be installed under the table 3, and the beam 1 is provided with a container The accommodating groove 101 of the control box 2, on the inner side wall of the accommodating groove 101 and the corresponding outer side wall of the control box 2, one of them is provided with a slide rail groove 102, and the other is provided with a positioning protrusion 21. In an assembled state, the positioning protrusion 21 is clamped into the slide rail groove 102, and the slide rail groove 102 allows the positioning protrusion 21 to slide laterally therein.

[0034] In this embodiment, on the inner wall of the accommodating groove 101 and the outer wall of the control box 2, one of them is provided with a positioning protrusion 21, and the other is provided with a slide rail groove 102. When assembling, th...

Embodiment 2

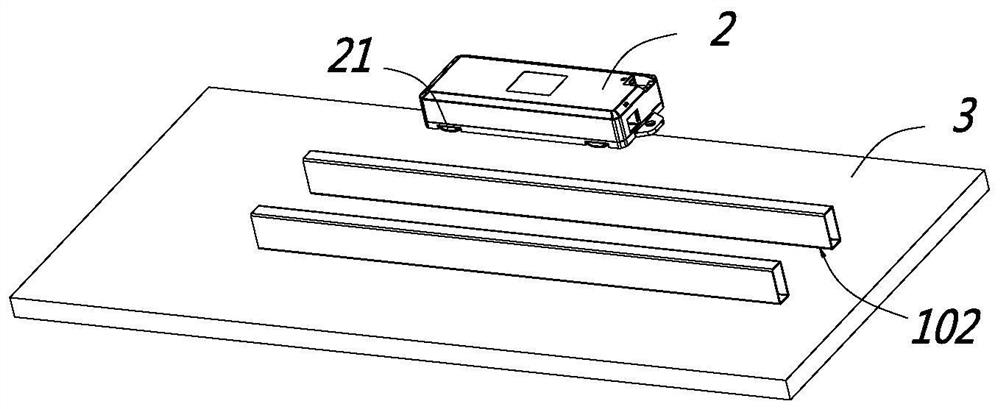

[0048] Such as Figure 7 As shown, the difference between the present embodiment and the first embodiment mainly lies in the design of the slide rail groove 102. The first embodiment is a more preferred solution, which can keep the cost very low, while the slide rail in this embodiment The groove 102 is an independently designed bar-shaped groove. The main purpose of this design is that the stability of the slide rail groove 102 is better, because similar to the arc chamfer 103 in the first embodiment, its size is relatively limited. If the arc chamfer 103 is small, the depth of the slide rail groove 102 is relatively small, so the slide rail groove 102 in the first embodiment is relatively limited by the size of the arc chamfer 103 itself.

[0049] In this embodiment, the slide rail groove 102 is an independent bar-shaped groove, and its size is not limited to the arc chamfer 103. The cost is higher than that of Embodiment 1, but the stability is better, and at the same time ...

Embodiment 3

[0051] This embodiment is a table frame for a lift table, which includes a beam, lifting columns installed on both sides of the beam, and a control box installed in the beam, the control box controls the lifting column to go up and down, and the control box is used between the beam and the beam. Embodiment 1 or Embodiment 2 or a rapid assembly structure equivalent thereto.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com