A continuous cosmetic packaging bottle packaging integrated equipment and production method thereof

A technology for packaging bottles and cosmetics, which is applied in the field of continuous cosmetic packaging bottle packaging equipment, and can solve problems such as affecting cosmetic packaging and packaging bottles that cannot be placed stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

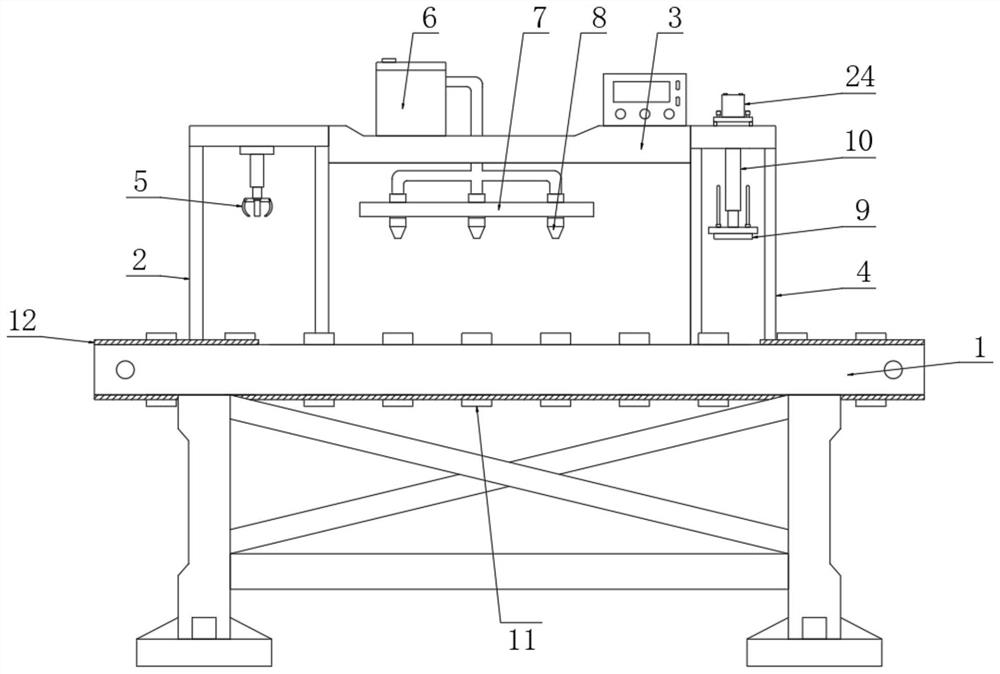

[0028] The present invention provides a technical solution: a continuous cosmetic packaging bottle packaging equipment, please refer to figure 1 , including workbench 1;

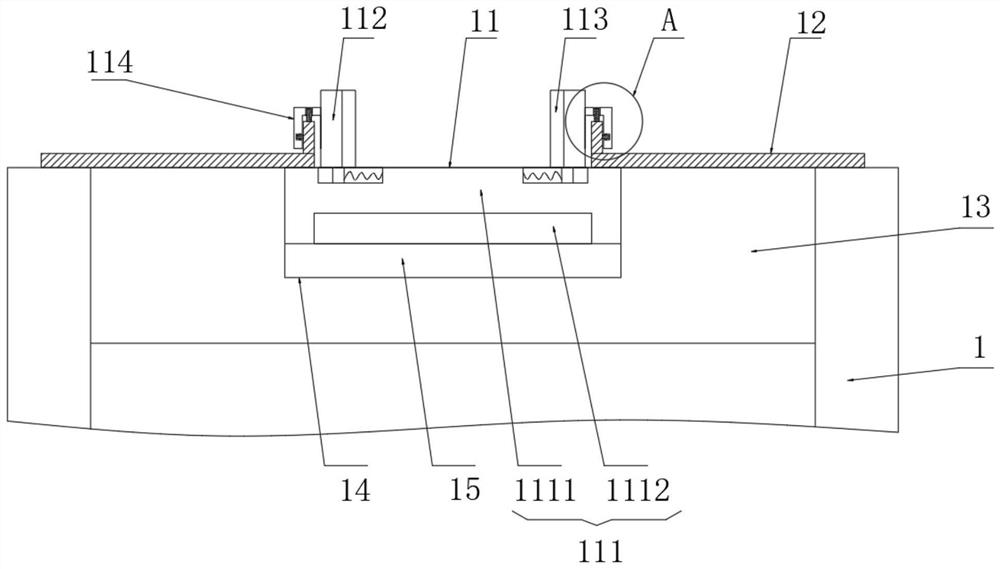

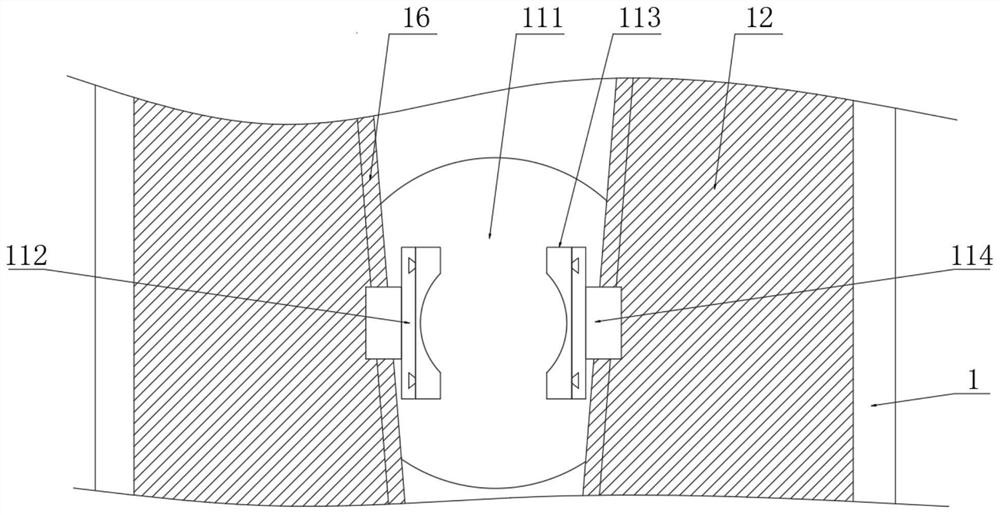

[0029] see figure 1 , the center of the inner cavity of the workbench 1 is fixed with a transmission device 13, the transmission device 13 includes a transmission roller and a conveyor belt, the conveyor belt is a metal conveyor belt, the conveyor belt is covered on the outer wall of the transmission roller, and the transmission roller is driven by the conveyor belt to transport the packaging bottles , the outer wall of the transmission device 13 is uniformly provided with a fixing device 11, and the outer wall of the top of the workbench 1 is fixedly installed in turn from left to right. The installation frame 2, the frame 3 and the support frame 4, the top inner wall of the installation frame 2 is slidingly installed with the manipulator 5, the manipulator 5 The servo slide table is installed on the inner...

Embodiment 2

[0037] see figure 1 with Image 6 , on the basis of Embodiment 1, the rear outer wall of the moving plate 7 is slidingly connected with the rear inner wall of the frame 3, the moving plate 7 can move up and down, the outer wall of the top of the moving plate 7 is fixedly connected with the screw rod 23, and the top end of the screw rod 23 extends to the frame 3, the outer wall of the top of the frame 3 is sleeved with a sleeve 21, the inner wall of the sleeve 21 is provided with an internal thread, the rotation of the sleeve 21 makes the screw 23 move upward or downward, and the outer wall of the bottom of the sleeve 21 is connected to the outer wall of the top of the frame 3. Rotate the connection so that the casing 21 can only rotate at the top wall of the frame 3. The outer wall of the casing 21 is evenly provided with four groups of rotating rods 22. The rotating rods 22 are fixedly connected with the sleeve pipe 21. Hold the rotating rod 22 to rotate, so that The casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com