Method for extracting sodium sulfite and sodium sulfate by using sulfur dioxide-containing flue gas and system

A technology of sodium sulfite and sulfur dioxide, applied in alkali metal sulfite/sulfite, chemical instruments and methods, preparation of alkali metal sulfite, etc., can solve problems such as affecting the content of anhydrous sodium sulfite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

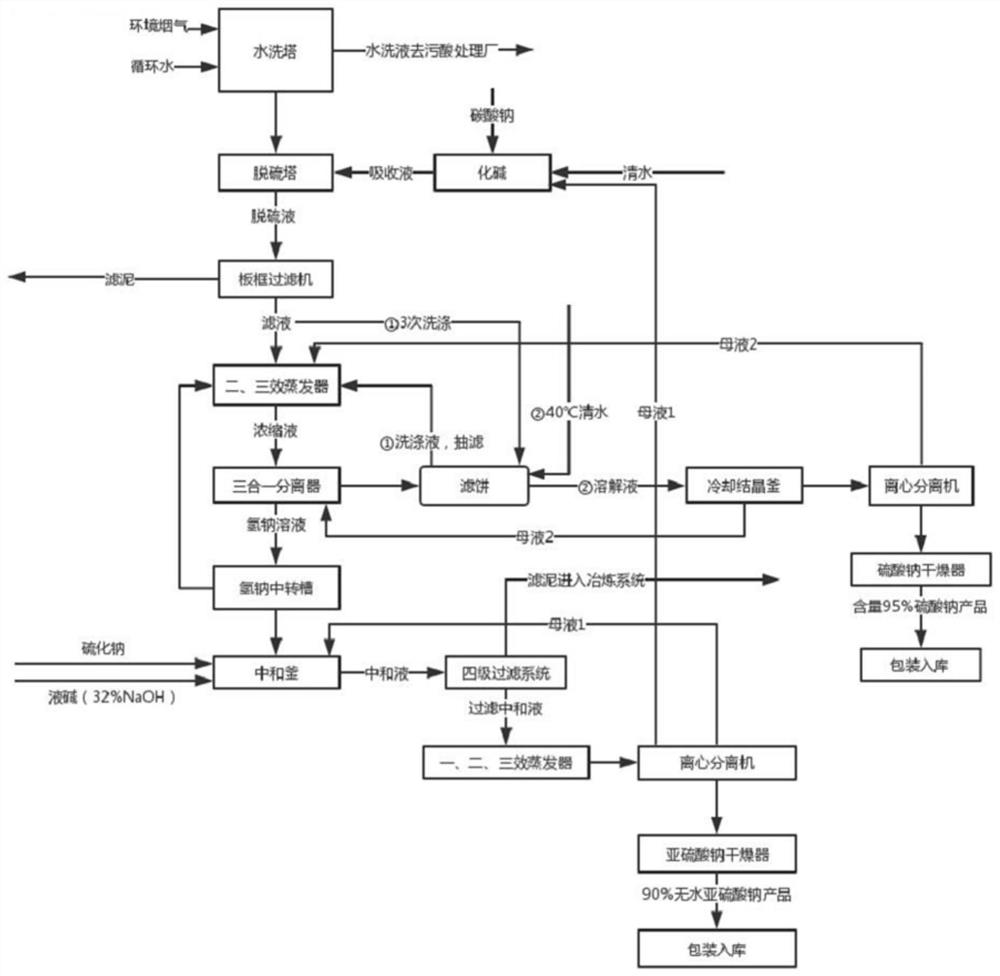

Method used

Image

Examples

Embodiment Construction

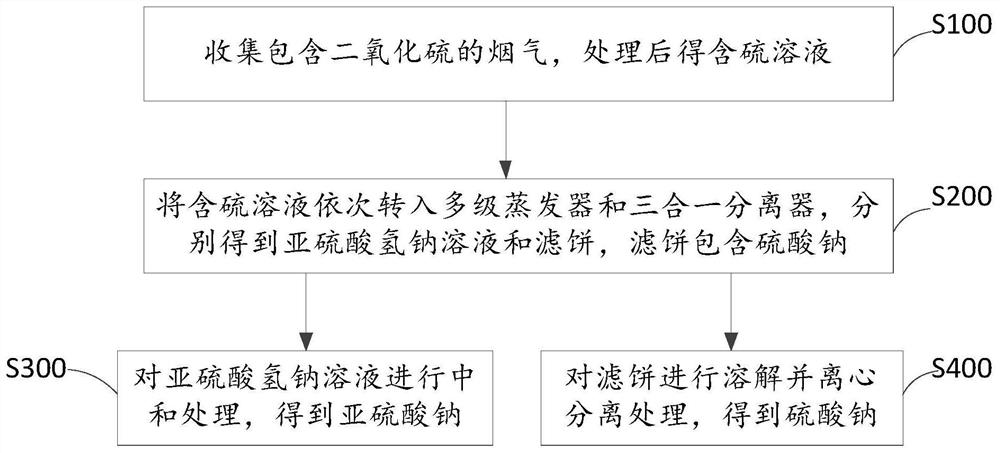

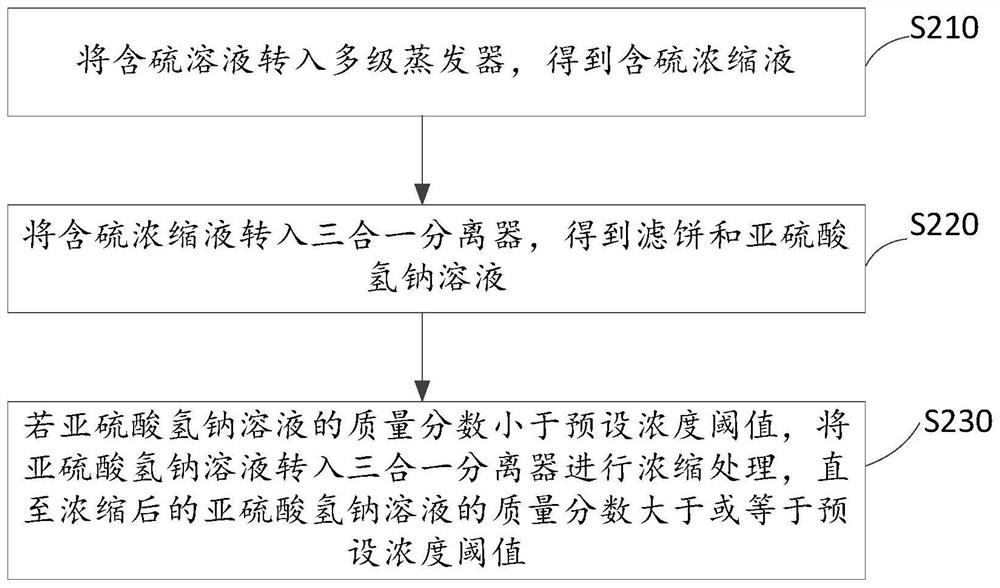

[0047] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0048] In some processes described in the specification and claims of the present invention and the above-mentioned drawings, a plurality of operations appearing in a specific order are contained, but it should be clearly understood that these operations may not be performed in the order in which they appear herein Execution or parallel execution, the serial number of the operation, such as 100, 200, etc., is only used to distinguish different operations, and the serial number itself does not represent any execution order. Additionally, these processes can include more or fewer operations, and these operations can be performed sequentially or in parallel. It should be noted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com