Ceramic glazed tile and preparation method thereof

A glazed tile and ceramic technology, applied in the field of architectural ceramics, can solve the problems of easy reduction of the fracture modulus of finished ceramic tiles, product deformation, obvious differences in whiteness and oxidation degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

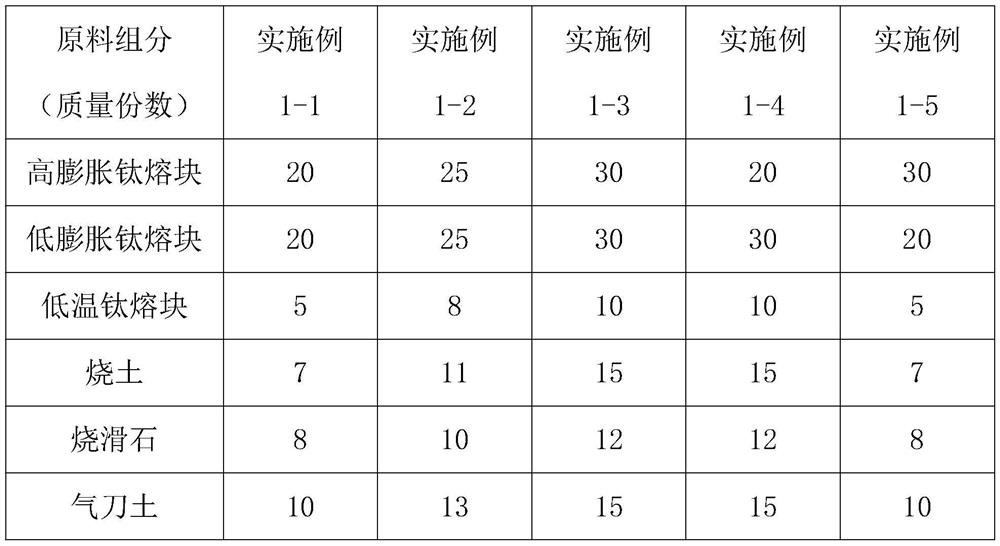

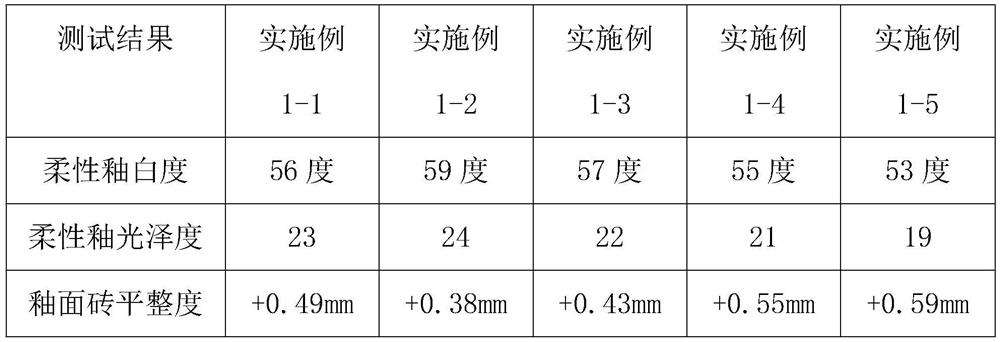

Examples

preparation example Construction

[0075] A preparation method of the above-mentioned ceramic glazed tiles, comprising the following steps:

[0076] A, the flexible glaze raw material is prepared flexible glaze according to proportion;

[0077] B. Add the surface glaze raw materials into the ball mill according to the proportion, mix sodium carboxymethyl cellulose, sodium tripolyphosphate and water into the ball mill for ball milling, and obtain the surface glaze;

[0078] C. Apply the top glaze of step B to the upper surface of the ceramic brick body to form a top glaze layer;

[0079] D. Apply the flexible glaze in step A to the bottom surface and / or side of the ceramic tile body in step C to form a flexible glaze layer, wherein the bonding force of the flexible glaze is ≥0.1MPa;

[0080] E. Drying and firing the ceramic brick body in step D to form glazed bricks.

[0081] Furthermore, this technical solution also proposes a method for preparing ceramic glazed tiles, wherein the adhesive force of the flexib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Modulus of rupture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap