Preparation method of porcelain deformation-resistant glazed tile and prepared porcelain deformation-resistant glazed tile

A technology of anti-deformation and glazed tiles, applied in the field of architectural ceramics, can solve problems affecting product quality, inconsistent ribs and lattice bottoms, and flatness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

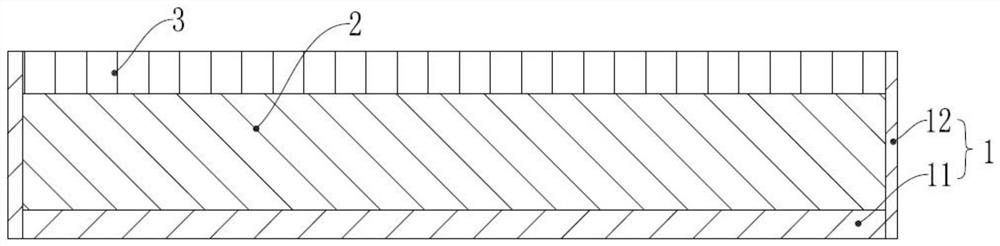

[0030] A method for preparing porcelain anti-deformation glazed tiles includes the following steps:

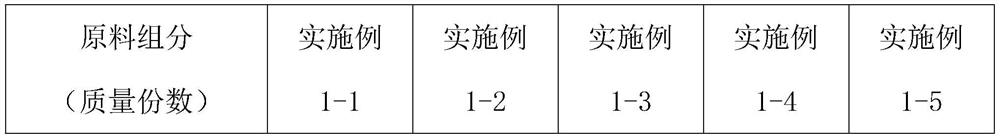

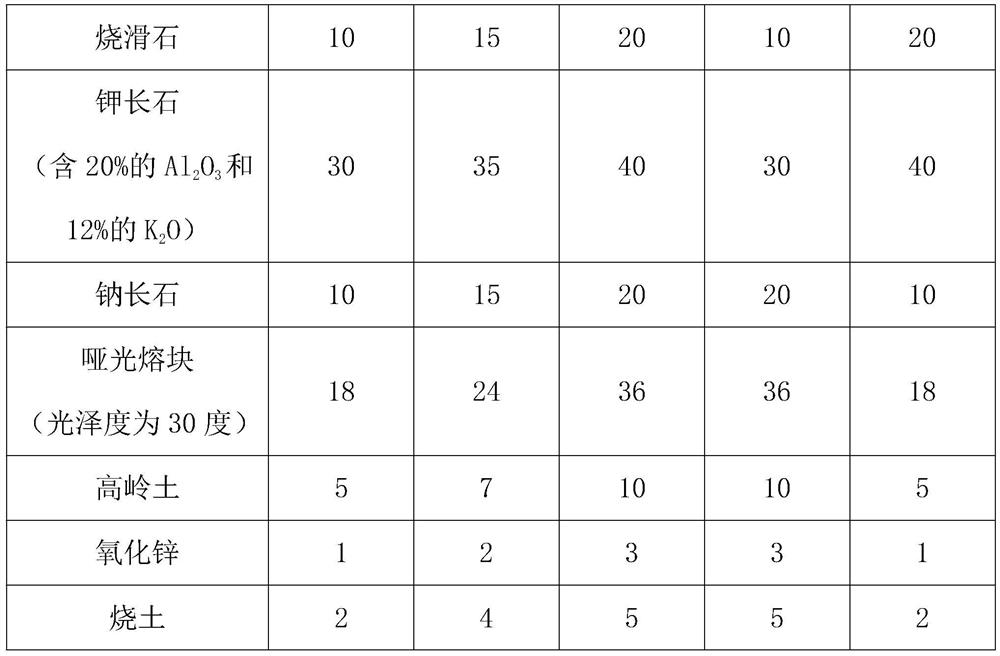

[0031] A. Prepare the anti-deformation glaze according to the ratio of the anti-deformation glaze materials, wherein the anti-deformation glaze materials include potassium feldspar and matt frit;

[0032] B. Add the surface glaze raw materials into the ball mill according to the ratio to obtain the surface glaze;

[0033] C. Apply the glaze cloth of step B to the upper surface of the porcelain tile body 2 to form the glaze layer 3;

[0034] D. Apply the anti-deformation glaze cloth of step A to the bottom and / or side surfaces of the porcelain tile body of step C to form an anti-deformation glaze layer 1, wherein the melting temperature of the anti-deformation glaze is the same as that of the porcelain tile body 2. The difference between the melting temperatures of ≤3°C, and the difference between the expansion coefficient of the deformation-resistant glaze and the expansion coefficien...

Embodiment 2-1

[0127] Example 2-1: The specific gravity of the anti-deformation glaze used for roller coating is 1.5, and the specific gravity of the anti-deformation glaze used for brush coating is 1.55;

Embodiment 2-2

[0128] Example 2-2: The specific gravity of the anti-deformation glaze used for roller coating is 1.6, and the specific gravity of the anti-deformation glaze used for brush coating is 1.64;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap