A device for cleaning the ground of rock foundation pit

A foundation pit and ground technology, applied in road cleaning, cleaning methods, construction and other directions, can solve problems such as low efficiency and incomplete cleaning of rock formation foundation grooves, achieve simple materials, solve low cleaning efficiency, and save labor costs and funds. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

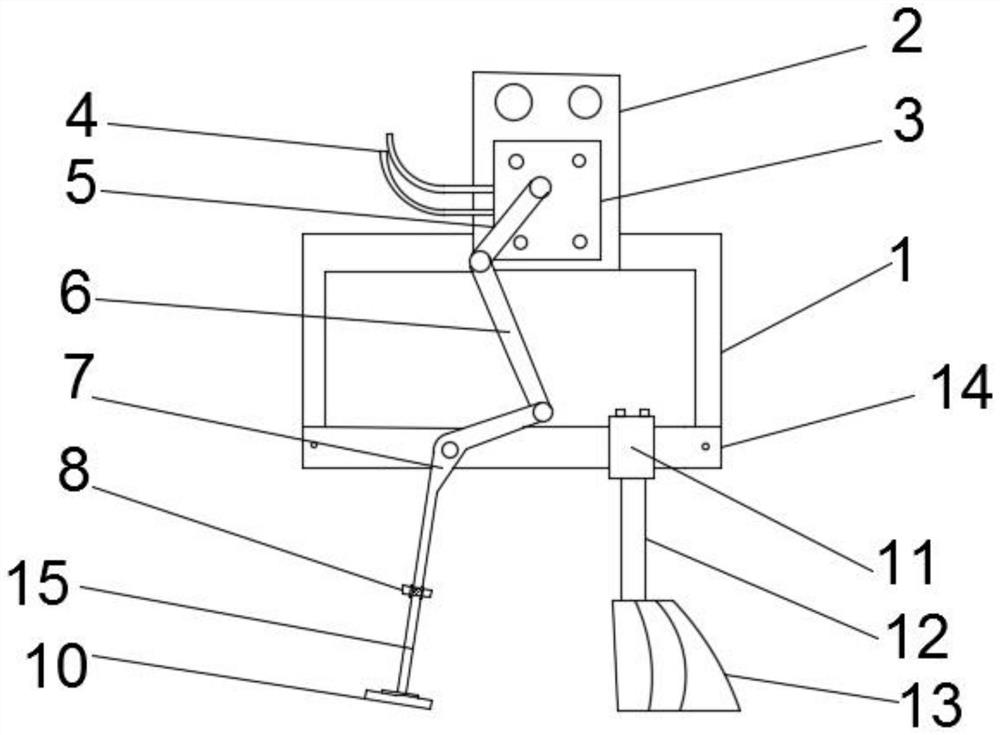

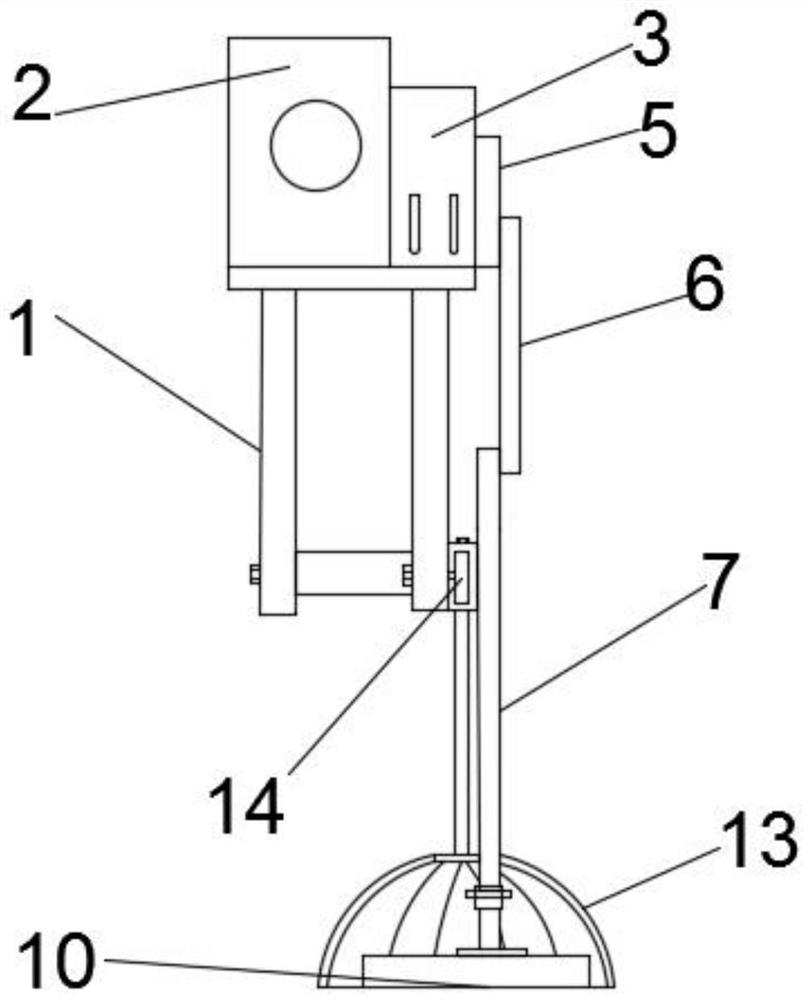

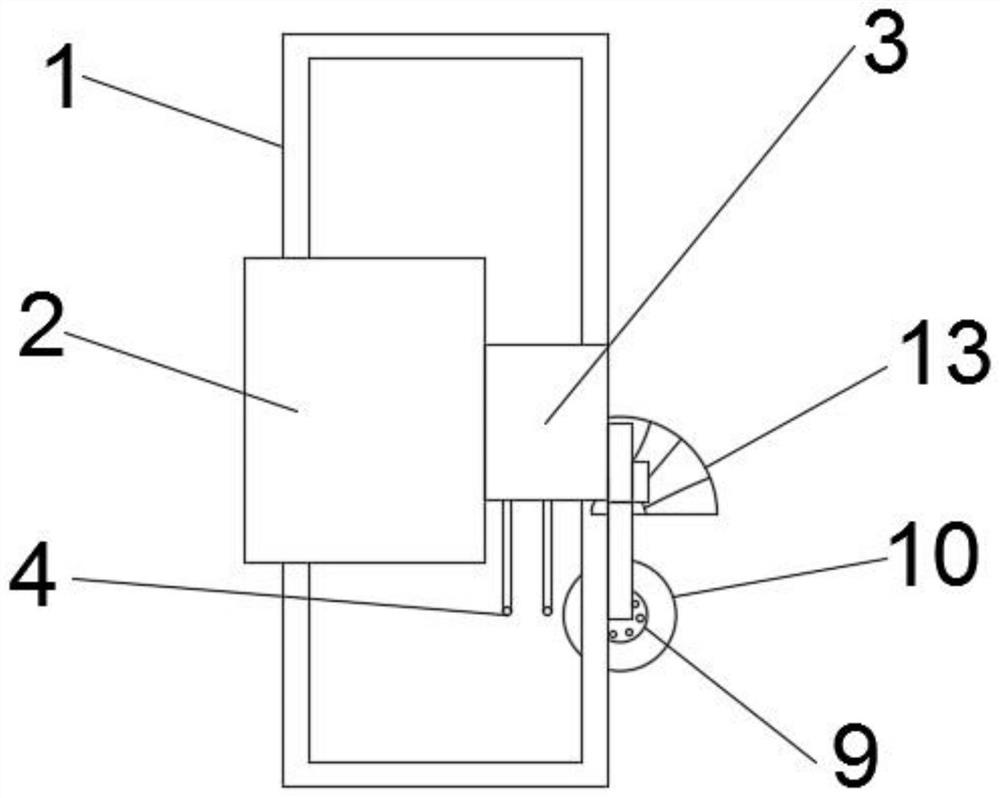

[0048] like Figure 1-6Shown: A device for ground cleaning of rock foundation pits, including a transmission unit, a cleaning unit and a fixed unit, the transmission unit is installed on one side of the fixed unit, the transmission unit is fixedly connected with the fixed unit, and one end of the cleaning unit is movable with the transmission unit Connection, the other end of the cleaning unit is movably connected with the fixed unit;

[0049] The transmission unit includes an output part and a first transmission rod 5, the first transmission rod 5 is rotatably connected with a second transmission rod 6, the second transmission rod 6 is rotatably connected with a swing rod 7, and the first transmission rod 5 is installed on the outside of the output part, The first transmission rod 5 is located on the upper side of the second transmission rod 6, the second transmission rod 6 is located on the upper side of the swing rod 7, the swing rod 7 is movably connected with the cleaning...

Embodiment 2

[0059] Use the transmission mode of the motor and the shaft to replace the transmission mode of the hydraulic motor 3 and the oil pipe 4, abandon the use of the coupling 8, directly use the swing rod 7 to fix the wire brush 10, and adjust the angle of the swing rod 7. It has the ability to swing left and right, and has the function of cleaning.

[0060] Instructions:

[0061] The device is connected to the excavator stick and boom, and the oil pipe 4 is connected to the excavator hydraulic oil pipe. The hydraulic motor 3 in the output part drives the first transmission rod 5 to rotate, and the first transmission rod 5 drives the second transmission rod 6. The second transmission rod 6 drives the swing rod 7, and the swing rod 7 drives the lower lower rod 12 and the wire brush 10 to swing through the cross-shaped universal joint bearing, and the rotated and cleaned garbage enters the storage box 13. The position of the storage box 13 is limited by the bolts and rotating parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com