Construction method for pulling joint pipe in underground diaphragm wall section connection construction

A technology of underground diaphragm wall and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., and can solve the problems of cast dead cannot be pulled out, collapse, joint pipe with high bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the application will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the application. .

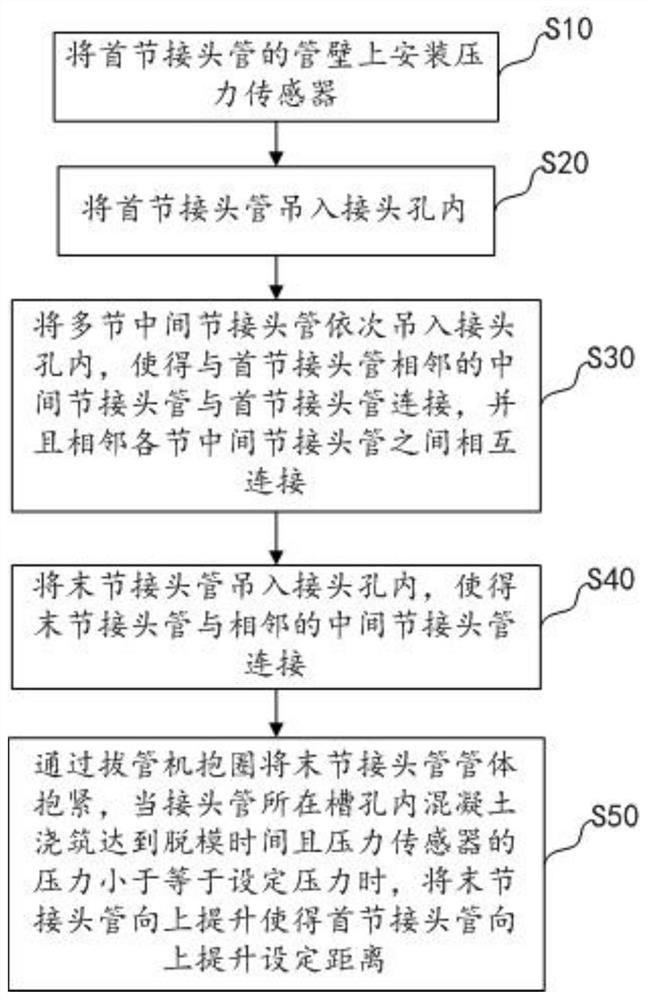

[0020] Such as figure 1 Shown is a schematic diagram of the first embodiment of the present application, including the following steps:

[0021] S10. Install a pressure sensor on the pipe wall of the first joint pipe.

[0022] In this embodiment, the construction of the underground diaphragm wall section is divided into the first-stage slot hole and the second-stage slot hole. Joint holes are set at both ends of the first-stage slot hole, and the joint pipe needs to be lowered to the joint before pouring in the first-stage slot hole. In the hole, because the joint hole is deep, it generally requires multiple joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com