A kind of prefabricated assembly building, construction method, working method

A prefabricated assembly, building technology, applied in the direction of protective buildings/shelters, building construction, construction, etc., can solve the problem of lack of dampers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

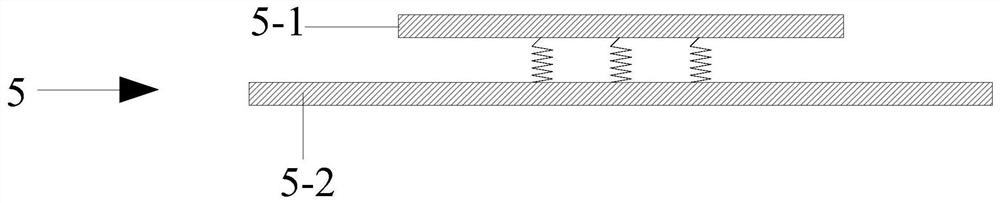

[0037] Embodiment 1, for a friction damper, its energy consumption is related to three parameters: the pressure between the friction objects, the friction coefficient between the friction objects, and the friction distance.

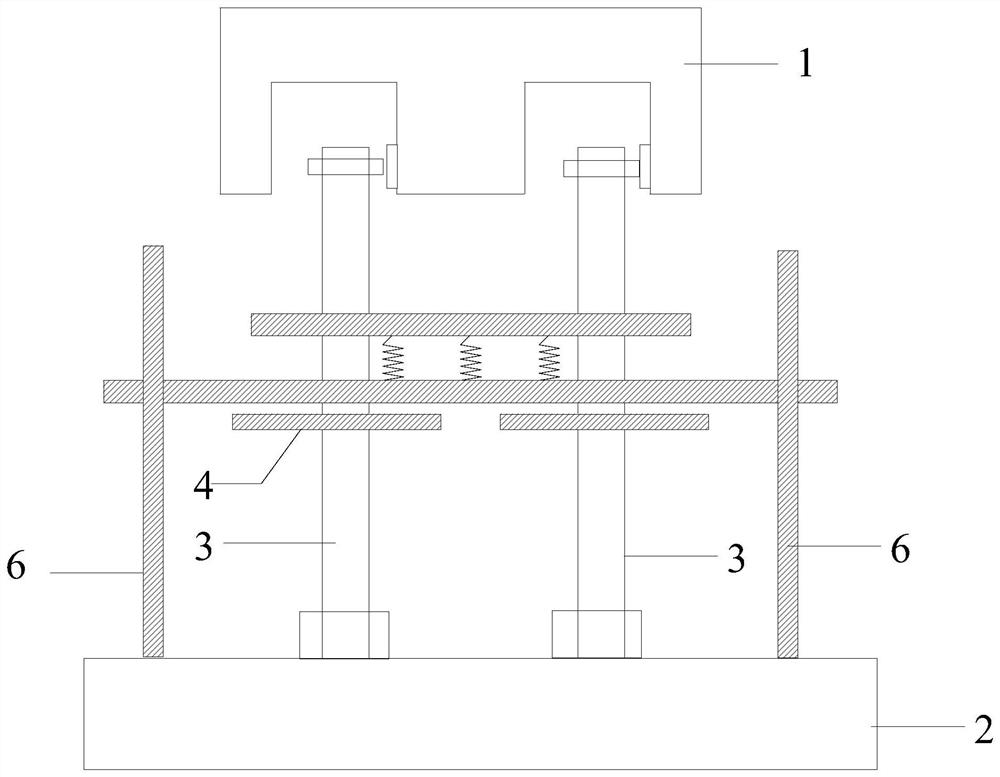

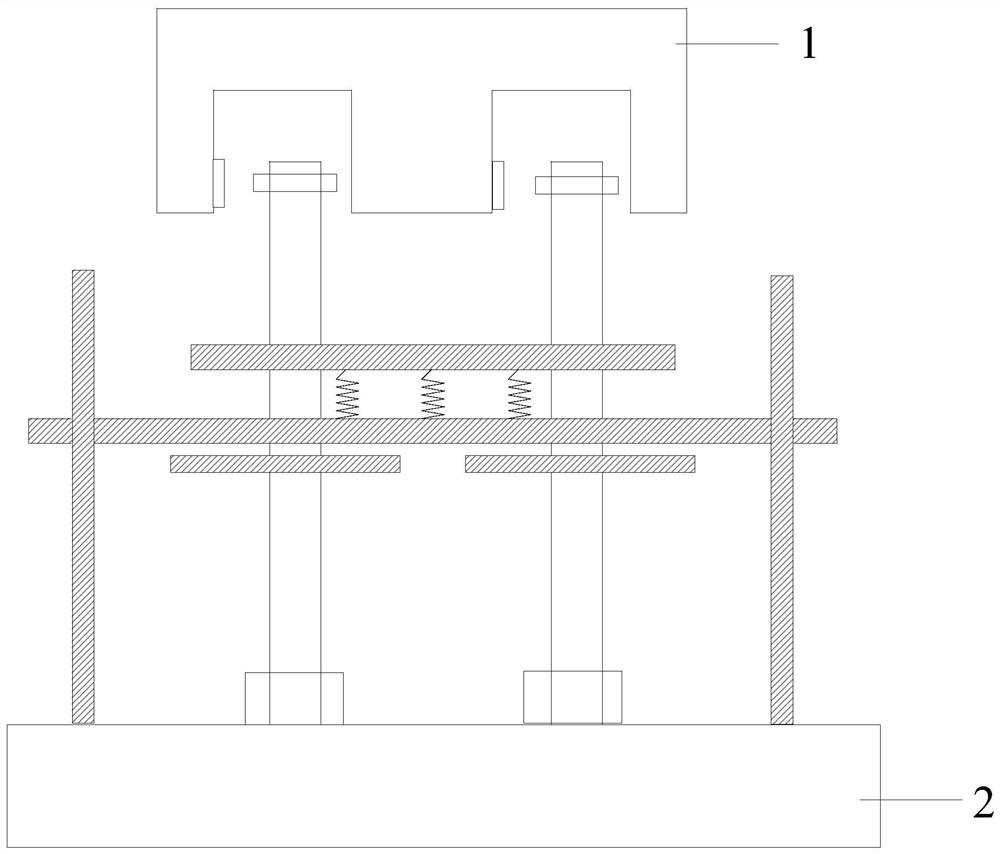

[0038] A prefabricated building, comprising a prefabricated upper beam 1, a prefabricated lower beam 2, and an amplitude adjustment damper installed between the prefabricated upper beam 1 and the prefabricated lower beam 2;

[0039] The amplitude adjustment damper includes: a first half-range damping unit and a second half-range damping unit;

[0040] The first half-stroke damping unit includes: at least two vertical rotation rods 3, a frictional damping part 5, and a guide column 6;

[0041] The vertical rotation rods are all connected to the prefabricated lower beam 2 through bearing rotation;

[0042] The upper part of the vertical rotation rod is provided with a horizontal gear, and the prefabricated upper beam 1 is provided with a rack corresponding...

Embodiment 2

[0066] The second design: the rotation directions of the vertical rotation rod of the first half-stroke damping unit and the vertical rotation rod of the second half-stroke damping unit are the same.

[0067] The thread direction of the vertical rotation rod of the first half-stroke damping unit is opposite to that of the vertical rotation rod of the second half-stroke damping unit.

[0068] Its working method, that is, the action process of the first half-stroke damping unit, and the function of the second half-stroke damping unit are the same as the first design of the second embodiment.

[0069] A method for installing a prefabricated building, comprising the following steps:

[0070] First, install the guide columns of the first half-stroke damping unit and the second half-stroke damping unit on the prefabricated lower beam 2;

[0071] Second, a fixed rack is installed on the underside of the prefabricated upper beam 1;

[0072] Third, install the bearings of the first h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com