Assembly unit body of autoclaved aerated concrete external wall panels

A technology for autoclaving and assembling units, applied in the direction of walls, building reinforcements, structural elements, etc., can solve the problems of difficult to guarantee construction quality, complex construction site conditions, and rising labor costs for retaining rings. The effect of protection and stacking, reducing concrete cracking of exterior wall panels, and avoiding tensile cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

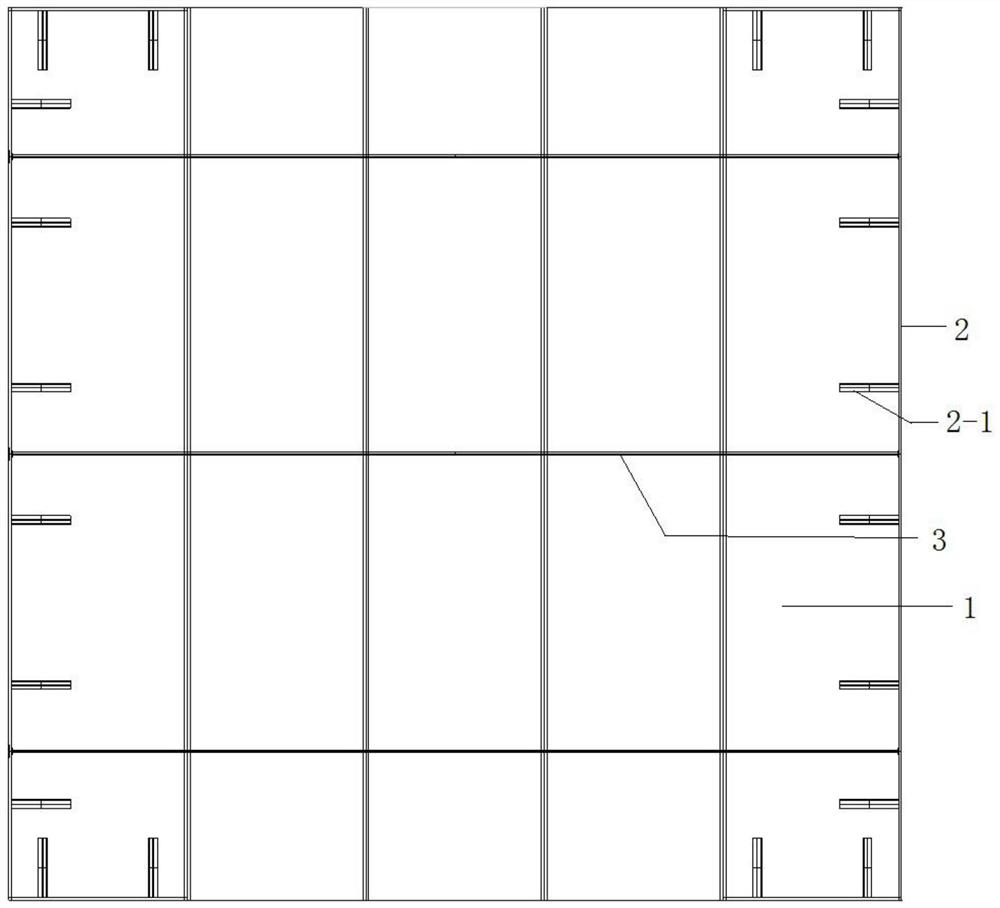

[0023] Such as figure 1 , figure 2 As shown, an autoclaved aerated concrete exterior wall panel assembly unit body includes: five autoclaved aerated concrete slats, side reinforcing keels and prestressed steel strands, and five autoclaved aerated concrete slats They are connected sequentially in the width direction. Each autoclaved aerated concrete slab is provided with perforations for the prestressed steel strands to pass through. The side reinforcement keel is connected to the outside of the autoclaved aerated concrete slab through a shear key structure. The stressed steel strand passes through the autoclaved aerated concrete slab and its two ends are connected to the side reinforcement keel.

[0024] In the above example, the side reinforcement keel is a flat steel structure, and the whole is arranged in a "U" shape. A row of angle steel shear keys is welded on one side of the side reinforced keel. The side reinforced keel is arranged longitudinally along the length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com