Glass lifting system for automobile and vehicle

A glass lifting and window glass technology, applied in the field of vehicles, can solve problems such as abnormal noise and deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

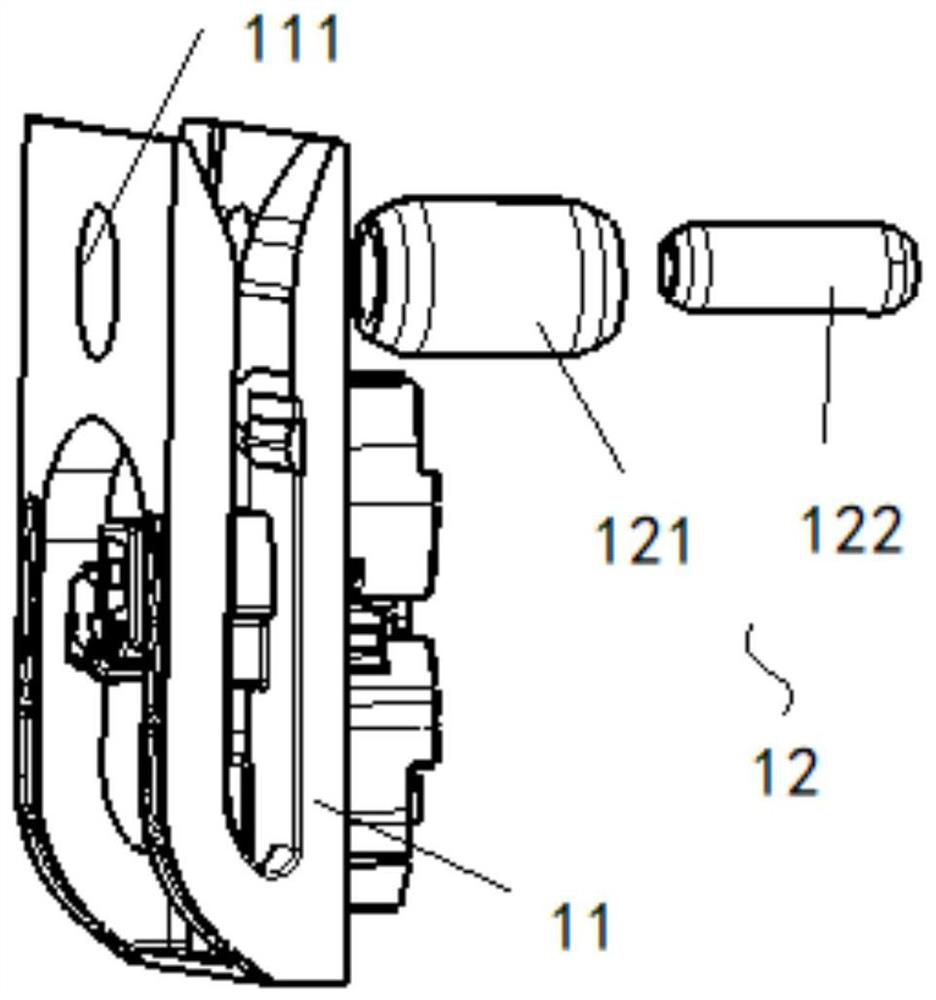

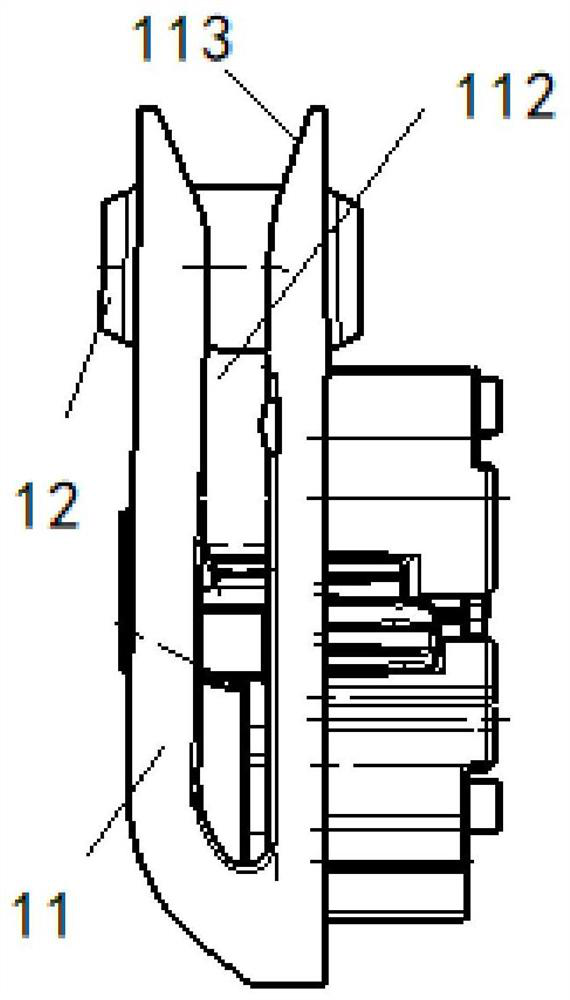

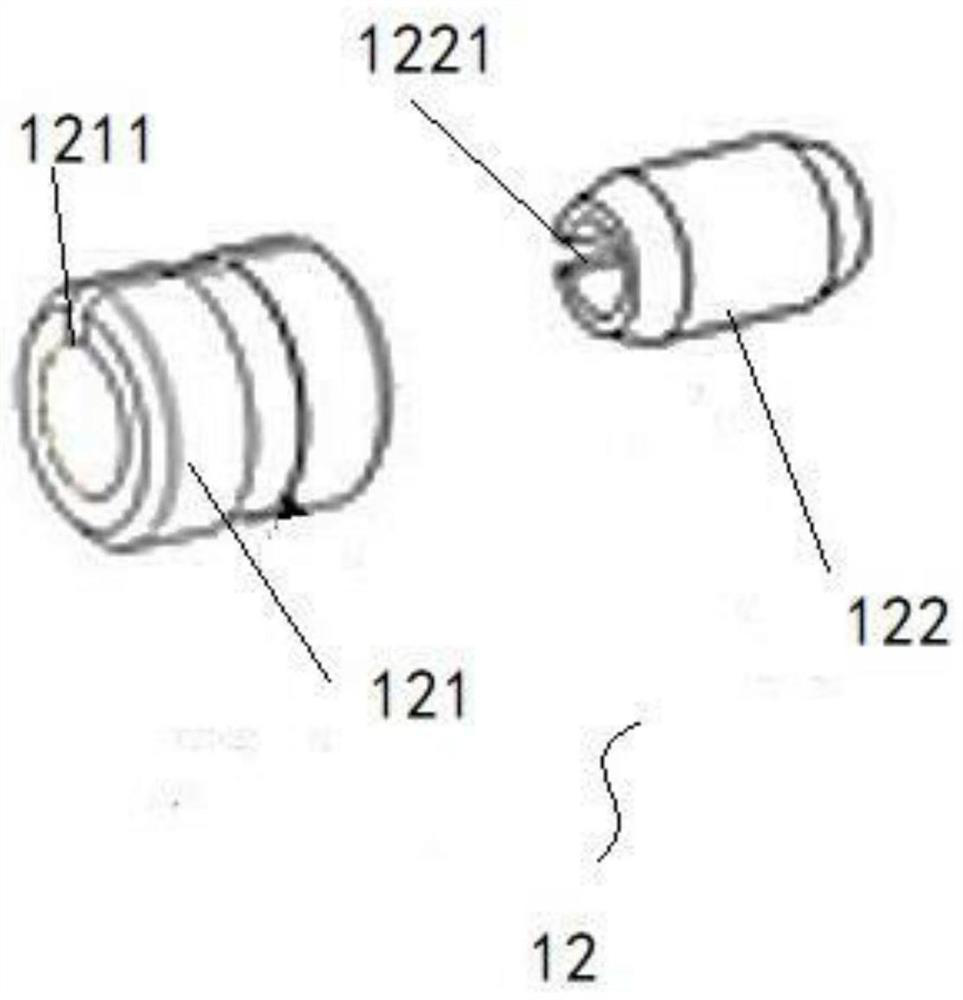

Embodiment 1

[0035] The existing front door glass lifting system includes a lifter (metal guide rail, metal slider), glass (with two brackets), and a trough (traditional section). The lifter and glass are connected by two bolts, and the structure of the glass clamp It is a metal structure, which is not conducive to light weight and workers' operation; at the same time, it adopts a metal clip connection method, which has no positioning in the X and Z directions, and is greatly affected by the assembly accuracy. If there is a deviation during the assembly process, the glass will be generated in the guide groove. Deflection, resulting in wear at the bottom of the guide groove (insufficient wear resistance at the bottom of the guide groove), and the risk of abnormal noise failure in the glass lift system.

[0036] Therefore, in order to solve the above problems, the embodiment of the present specification provides a glass lifting system for automobiles, especially, the embodiment of the present...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap