Rear embedded part anti-pulling strength detection device for building detection

A technology of pull-out strength and detection device, which is applied in the direction of measurement device, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of low functionality, conventional structure, and single data acquisition method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

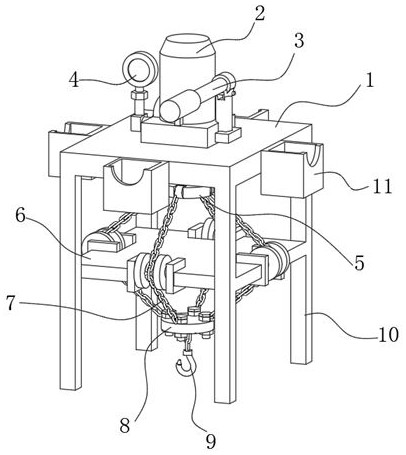

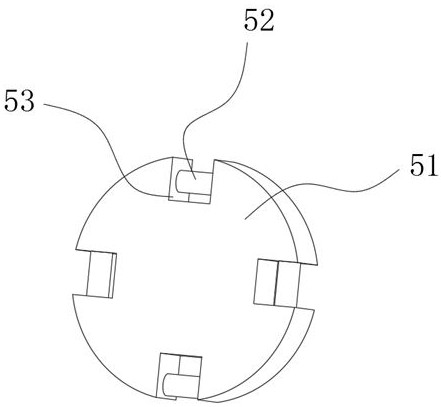

[0030] A device for detecting the pullout strength of rear embedded parts for building inspection, such as figure 1 As shown, it includes connecting seat 1, jack 2 is fixedly installed in the middle of the upper end of connecting seat 1, pressure gauge 4 is fixedly connected in the middle of the left end of jack 2, hydraulic rod 3 is arranged at the right end of jack 2, and the output end of jack 2 runs through the connecting seat 1 extends to the bottom of the connecting seat 1 and is fixedly connected with the connecting plate 5. The four corners of the lower end of the connecting seat 1 are fixedly connected with the supporting legs 10, and the four supporting legs 10 are fixedly installed with the limiting device 6. The middle part of the front end of the connecting seat 1 , the middle of the rear end, the middle of the left end and the middle of the right end are all fixedly connected with a storage box 11, and the outer surface of the connection plate 5 is equidistantly c...

Embodiment 2

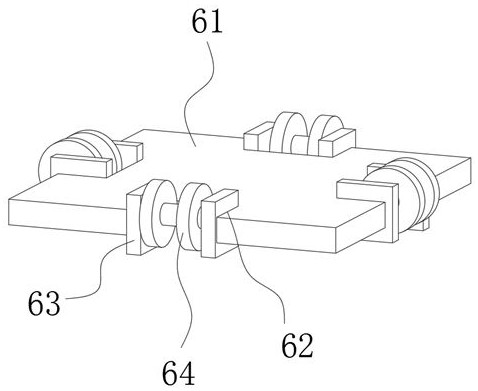

[0033] On the basis of Example 1, as Figure 2-7As shown, a device for detecting the pullout strength of post-embedded parts for building inspection includes a connecting seat 1, a jack 2 is fixedly installed in the middle of the upper end of the connecting seat 1, and a pressure gauge 4 is fixedly connected to the middle of the left end of the jack 2. The right end is provided with a hydraulic rod 3, the output end of the jack 2 extends through the connecting seat 1 to the bottom of the connecting seat 1 and is fixedly connected with the connecting plate 5, and the four corners of the lower end of the connecting seat 1 are fixedly connected with supporting legs 10, and the four supporting legs 10 The limit device 6 is fixedly installed between them, the front middle part, the rear end middle part, the left end middle part and the right end middle part of the connection seat 1 are all fixedly connected with a storage box 11, and the outer surface of the connection plate 5 is eq...

Embodiment 3

[0036] On the basis of Example 1, as Figure 8 As shown, a device for detecting the pullout strength of post-embedded parts for building inspection includes a connecting seat 1, a jack 2 is fixedly installed in the middle of the upper end of the connecting seat 1, and a pressure gauge 4 is fixedly connected to the middle of the left end of the jack 2. The right end is provided with a hydraulic rod 3, the output end of the jack 2 extends through the connecting seat 1 to the bottom of the connecting seat 1 and is fixedly connected with the connecting plate 5, and the four corners of the lower end of the connecting seat 1 are fixedly connected with supporting legs 10, and the four supporting legs 10 The limit device 6 is fixedly installed between them, the front middle part, the rear end middle part, the left end middle part and the right end middle part of the connection seat 1 are all fixedly connected with a storage box 11, and the outer surface of the connection plate 5 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com