Deep groove ball bearing channel super-finishing machine swing head

A technology of deep groove ball bearings and superfinishing machines, which is applied in superfinishing machines, grinding racks, and parts of grinding machine tools, etc. It can solve problems such as the influence of superfinishing quality, inconvenient center adjustment, and large vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

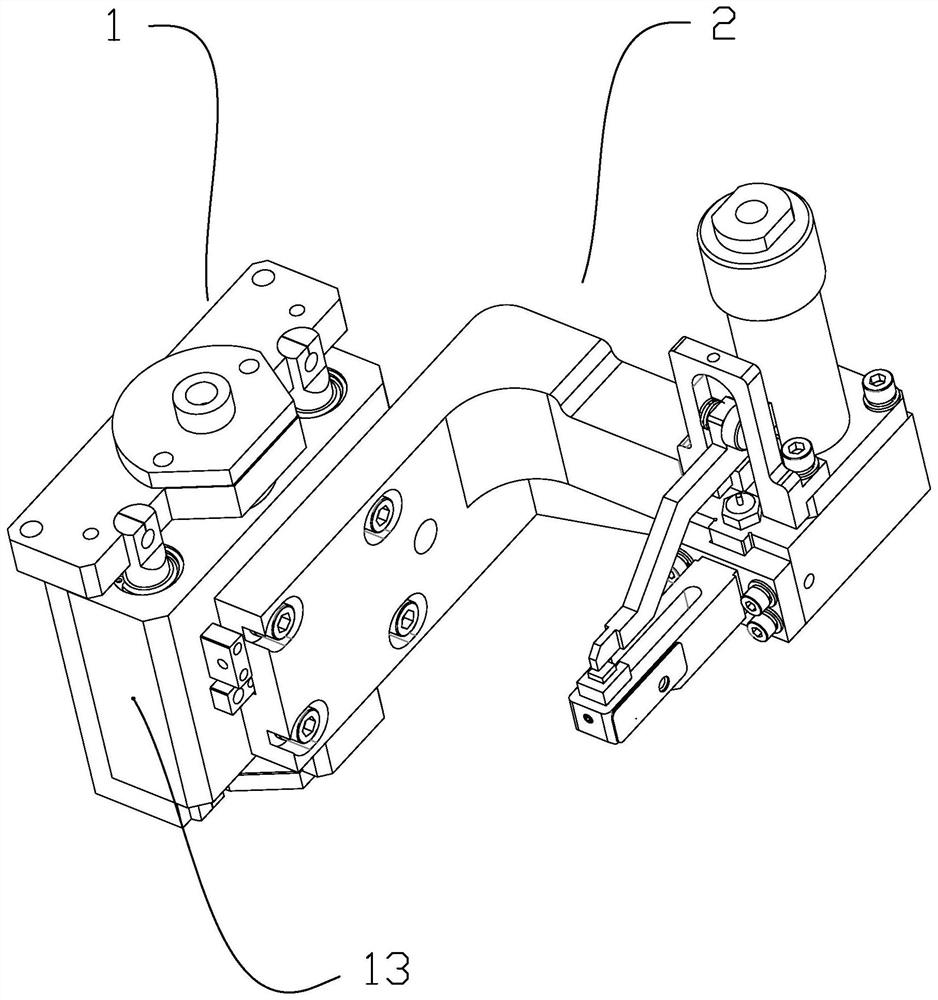

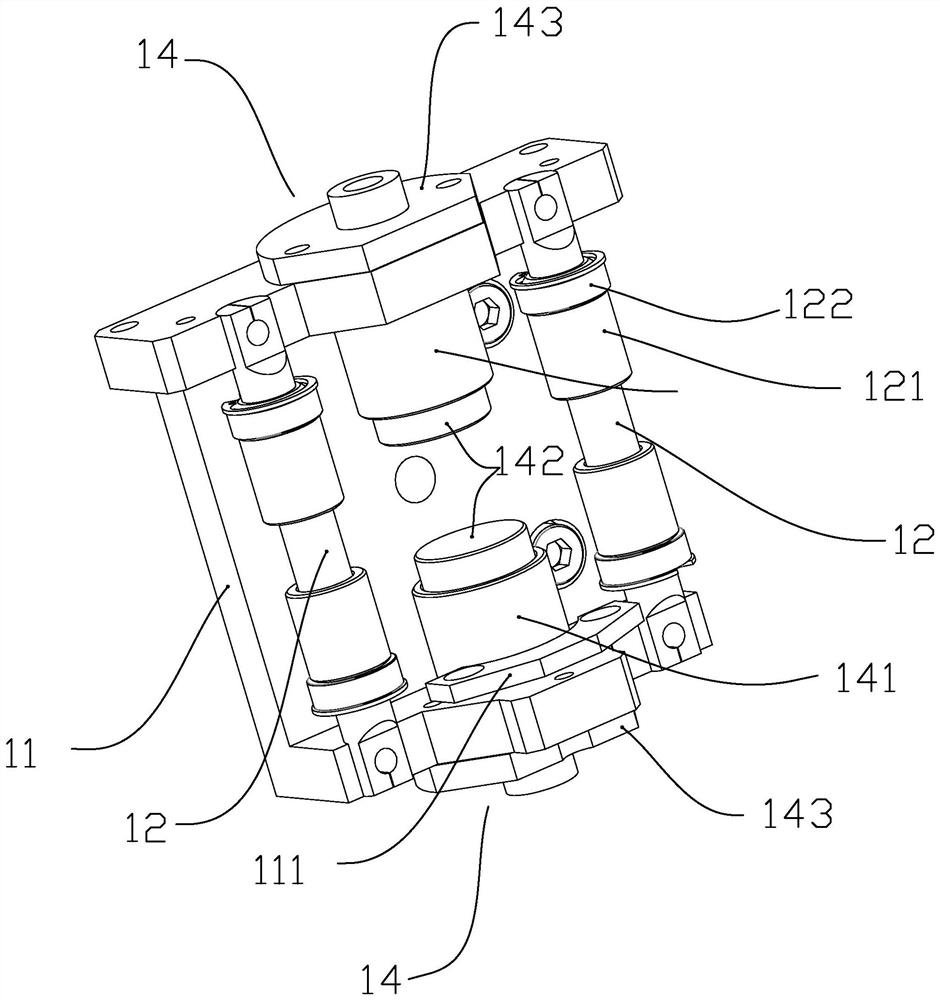

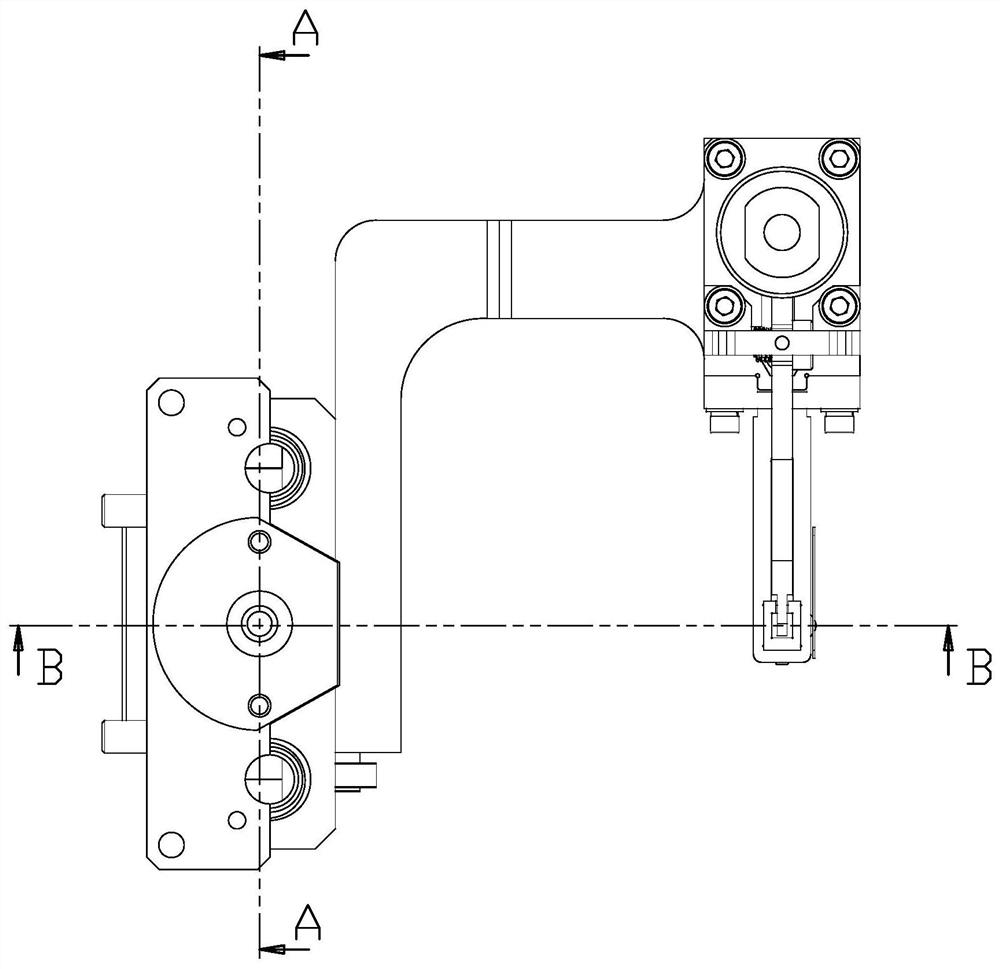

[0033] The specific embodiment of the present invention is such as Figure 1-8 As shown, a deep groove ball bearing groove super precision machine swing head includes a slider assembly 1 and an oil stone frame assembly 2, and the slider assembly 1 includes a slider bracket 11, a guide rod 12, a slider body 13 and a drive The driving part 14 that the sliding body 13 moves, the two ends of the guide rod 12 are fixed on the slider bracket 11 after passing through the slider body 13, and the driving part 14 drives the slider body 13 along the axis of the guide rod 12 To slide, the oilstone frame assembly 2 is fixed on the slider body 13 . The slider assembly 1 mainly realizes the up and down movement of the oil stone, that is, controls the oil stone to enter the working position and exit the working position. The guide rod 12 is made of Misumi hard chrome-plated smooth round rod. The preferred guide rod 12 is two. The rod 12 is fixed on the slider bracket 11, the slider body 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com