Fastening system for tiltable metallurgical treatment vessels

A technology of processing container and fixing system, applied in the direction of manufacturing converters, etc., can solve the problem that the circumferential support is not specially protected, hinder the thermal expansion of the processing container, etc., and achieve the effect of reliable movement and small temperature alternating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

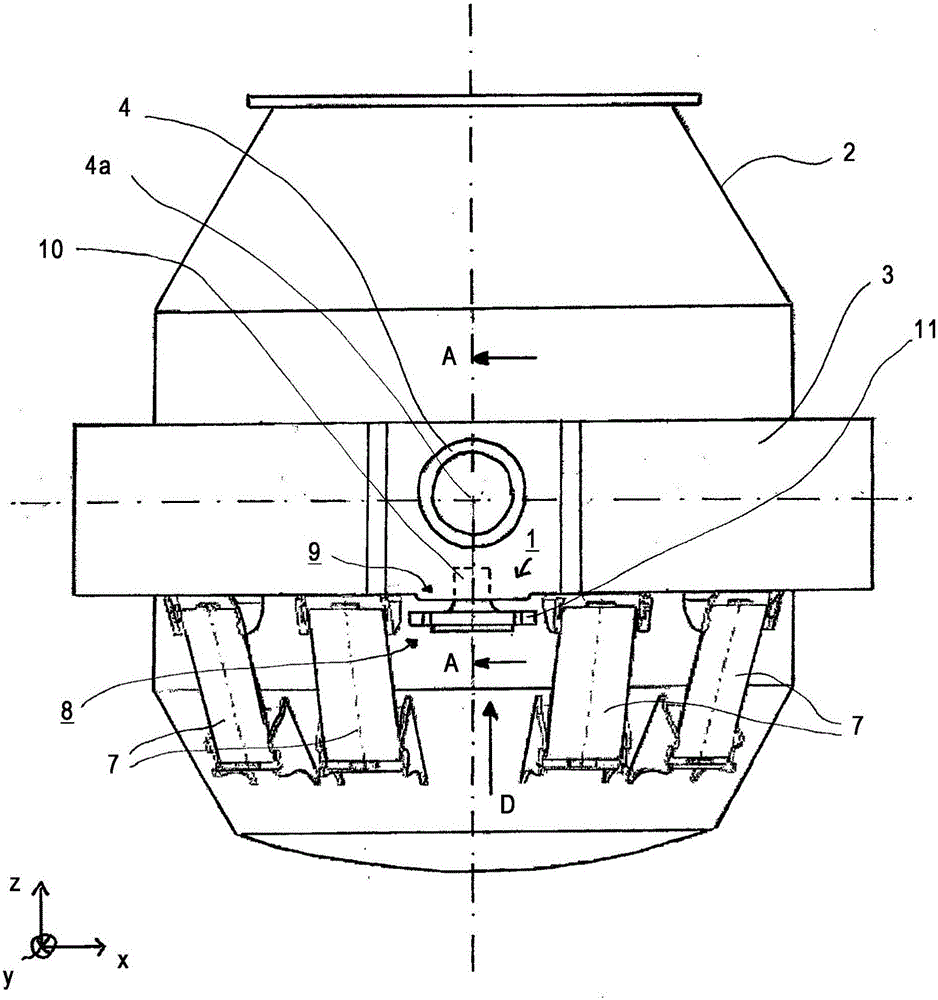

[0019] figure 1 The fixing system 1 according to the invention is shown in connection with a process vessel 2 in the form of a converter. The processing vessel 2 is suitable for the production and processing of liquid metals and metal alloys and is always referred to below for short as a converter, although this should not be understood in a restrictive manner.

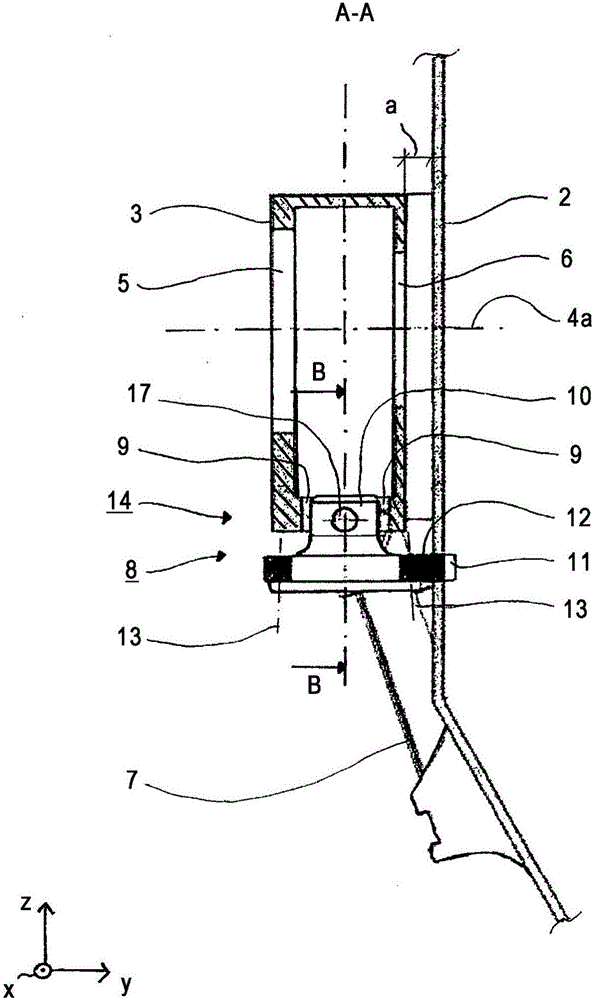

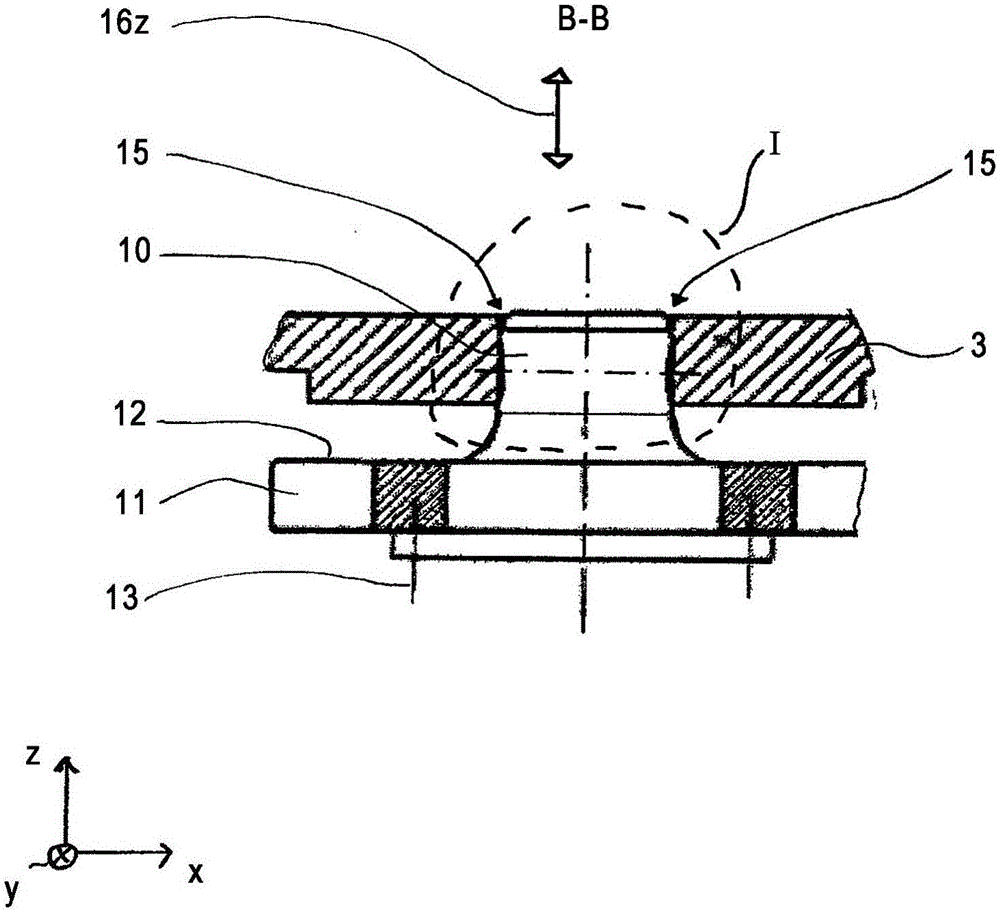

[0020] The converter 2 is surrounded by a support ring 3 with a distance a. shows along the figure 1 The sectional view of the line A-A of figure 2 It is stated that the support ring 3 has a box-shaped cross-section and is positioned at a distance a from the wall of the converter 2 .

[0021] On diametrically opposite sides of the support ring 3 two conically configured tilting pins 4 engage into the support ring 3 . The tilting pin 4 defines a tilting axis 4 a around which the support ring 3 in combination with the converter 2 is pivotable laterally. exist figure 1 Only the tilting pin 4 is shown in the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com