Electromechanical equipment capable of automatically snatching and conveying mechanical parts

A technology of transportation machinery and electromechanical equipment, which is applied in the direction of conveyor objects, manipulators, transportation and packaging, etc., and can solve the problems of inconvenient disassembly and maintenance of jaws, troubles, and waste of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

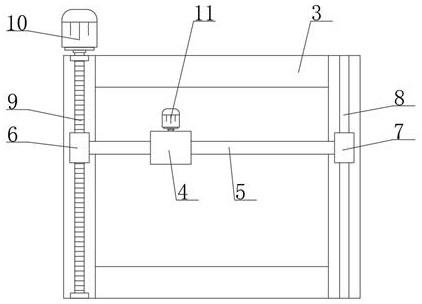

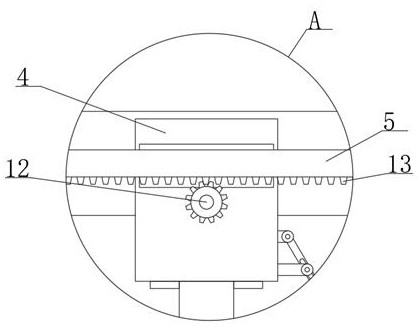

[0021] see Figure 1-5 , the present invention provides a technical solution: an electromechanical device for automatically grabbing and transporting mechanical parts, including a conveyor belt 1, jaws 2 and a top plate 3, and the inner rotation of the top plate 3 is connected with a threaded shaft 9 and a slide bar 8, and the slide bar 8 Symmetrical with the threaded shaft 9 about the midpoint of the top plate 3, the inside of the top plate 3 is slidably connected with a crossbar 5, one end of the crossbar 5 is connected with a second sliding block 6, and the other end is connected with a third sliding block 7, and the second sliding block 6 is screwed and connected with the threaded shaft 9, the third sliding block 7 is slidably connected with the slide bar 8, a first motor 10 is installed on one end of the top plate 3, and the output shaft of the first motor 10 is connected with the bottom end of the threaded shaft 9.

[0022] In this embodiment, the first motor 10 is start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com