Multidirectional aeration device for sewage treatment

A sewage treatment and aeration device technology, applied in water/sewage treatment, water/sewage treatment equipment, water aeration, etc., can solve problems such as the influence of aeration effect and single aeration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

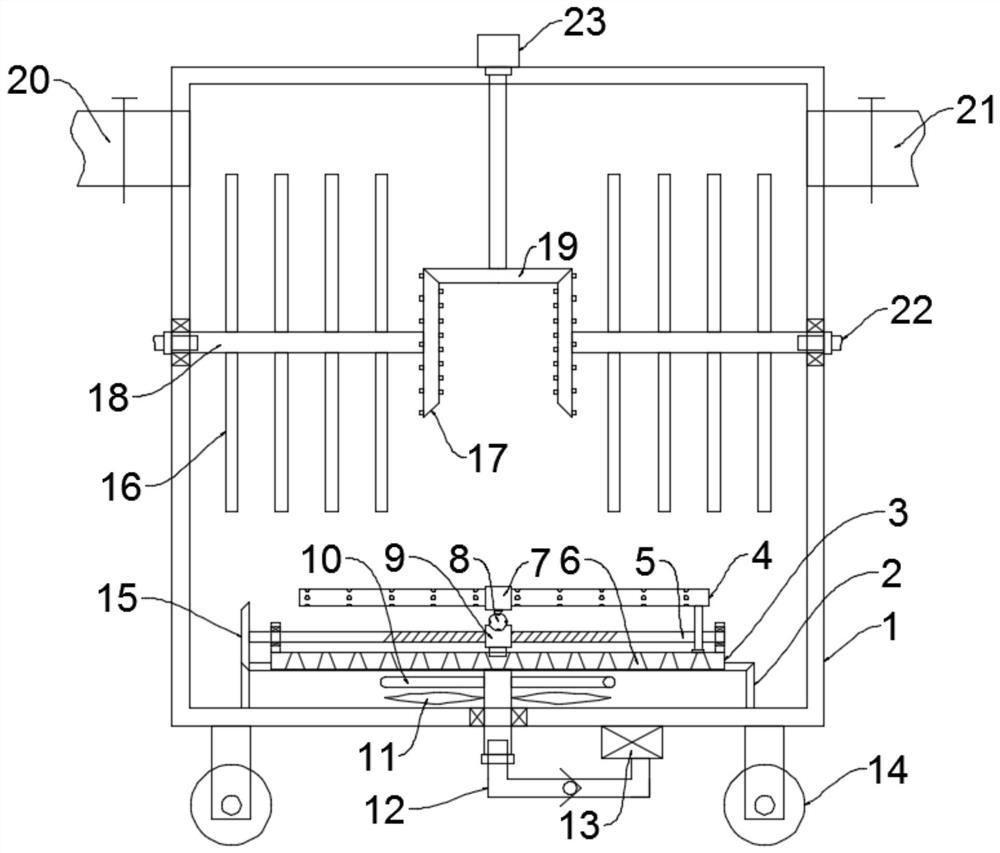

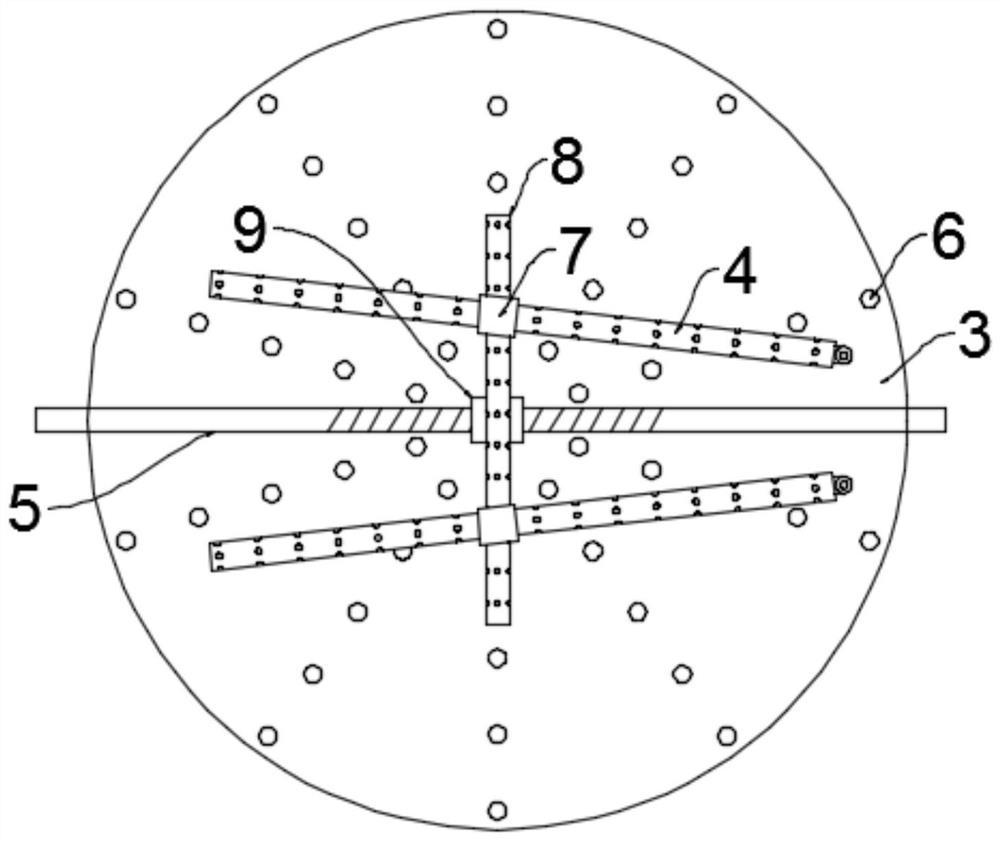

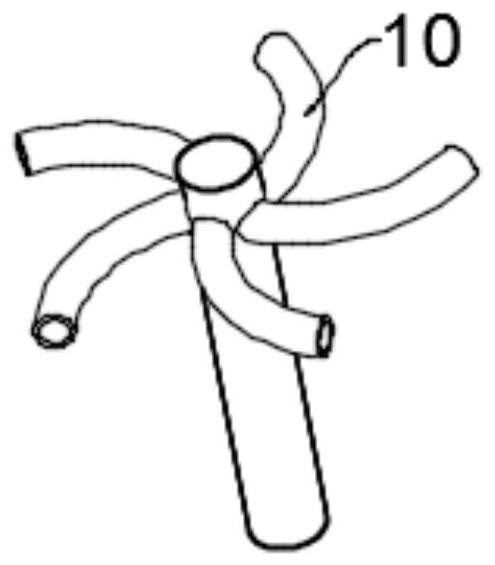

[0024] see Figure 1~3 , in an embodiment of the present invention, a multi-directional aeration device for sewage treatment includes a box body 1 and an aeration unit, and the bottom of the box body 1 is evenly and symmetrically fixed with rollers 14 to facilitate the movement of the device. The water inlet pipe 20 and the water outlet pipe 21 are connected, and valves are installed on the water inlet pipe 20 and the water outlet pipe 21. The aeration unit includes a mounting plate 3, a reciprocating screw rod 5, an internal thread sleeve 9, a first aeration pipe 8, The sliding sleeve 7, the second aeration pipe 4 and the arc-shaped air jet pipe 10, the installation plate 3 is arranged at the lower part of the inner cavity of the box body 1 and an installation shaft is fixed in the middle of the bottom, and the bottom end of the installation shaft runs through the bottom of the box body 1 and extends to Below the box body 1, the bottom end of the installation shaft penetrates...

Embodiment 2

[0028] see Figure 4 The difference between this embodiment of the present invention and Embodiment 1 is that a screw rod 24 is fixed at the bottom of the third bevel gear 19, and a second through hole is opened on the screw rod 24, and the size of both ends of the second through hole is larger than the middle size, When the screw rod 24 rotates, the sewage passes through the second through hole, and the change of flow velocity further disturbs the flow and generates air bubbles, which improves the aeration efficiency.

[0029]The working principle of the present invention is: when working, the first air supply pipe 12 supplies air to the installation shaft and then sprays out from the arc-shaped air injection pipe 10, and drives the installation shaft and the installation plate 3 to rotate under the reaction force, and the installation plate 3 drives it to reciprocate The screw rod 5, the first aeration pipe 8 and the second aeration pipe 4 revolve around to perform rotary ae...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com