Ultramicro nano bubble aeration device

A technology of nano-bubbles and aeration devices, which is applied in water aeration, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of insufficient dissolved oxygen and the inability of aerobic microorganisms to perform oxidative decomposition. Achieve the effect of enhancing oxygen mixing effect, high aeration effect and increasing aeration volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

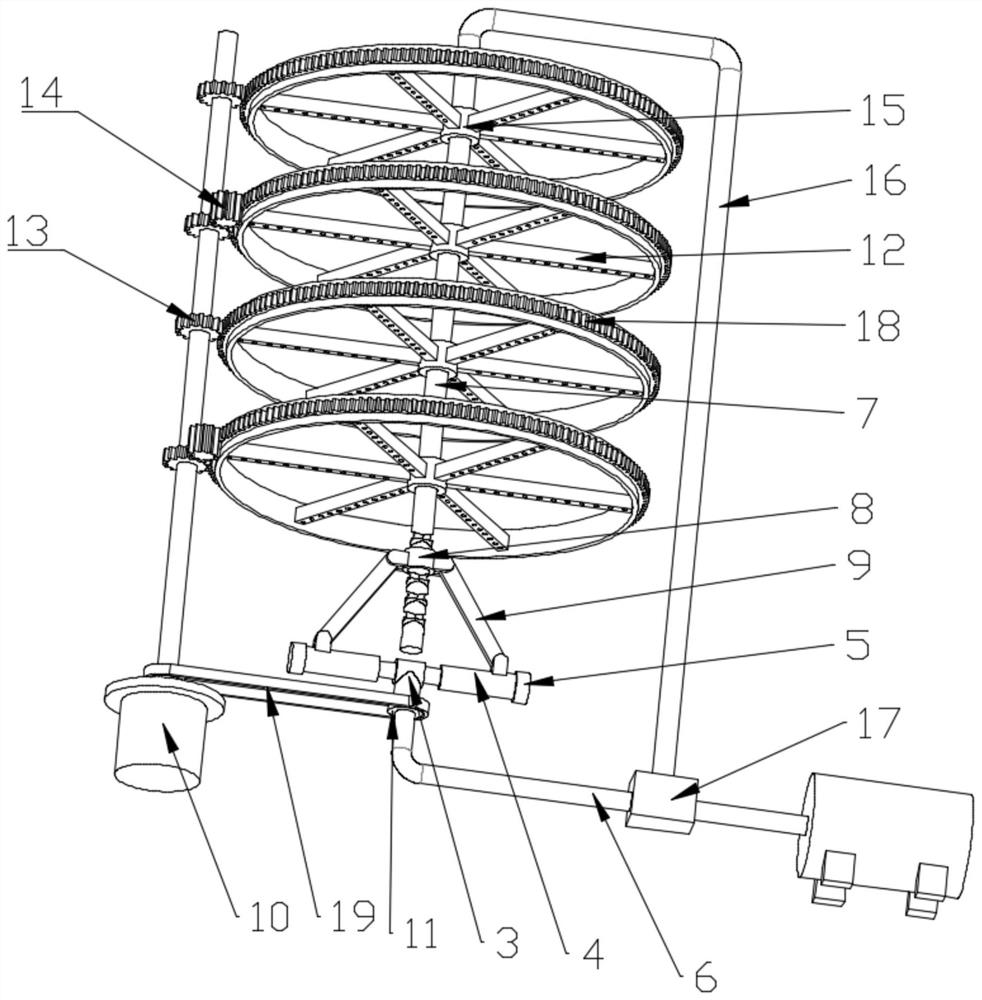

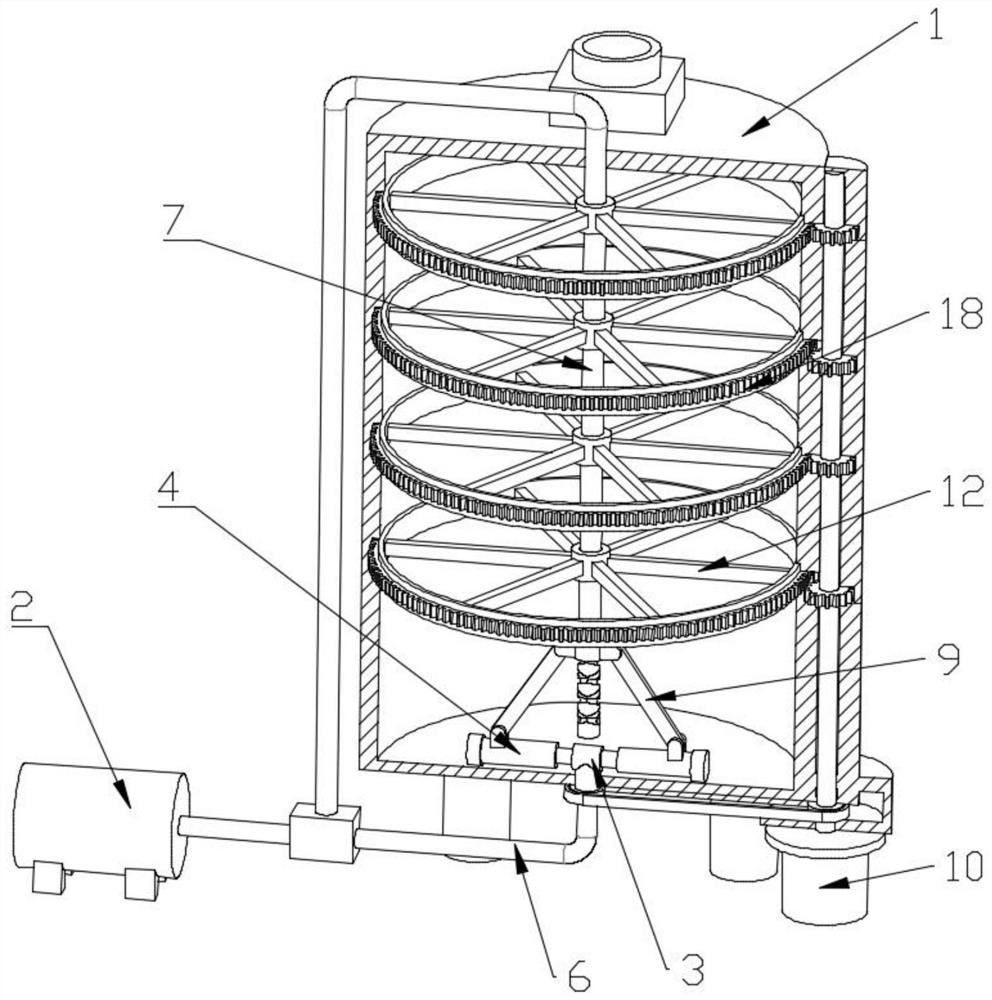

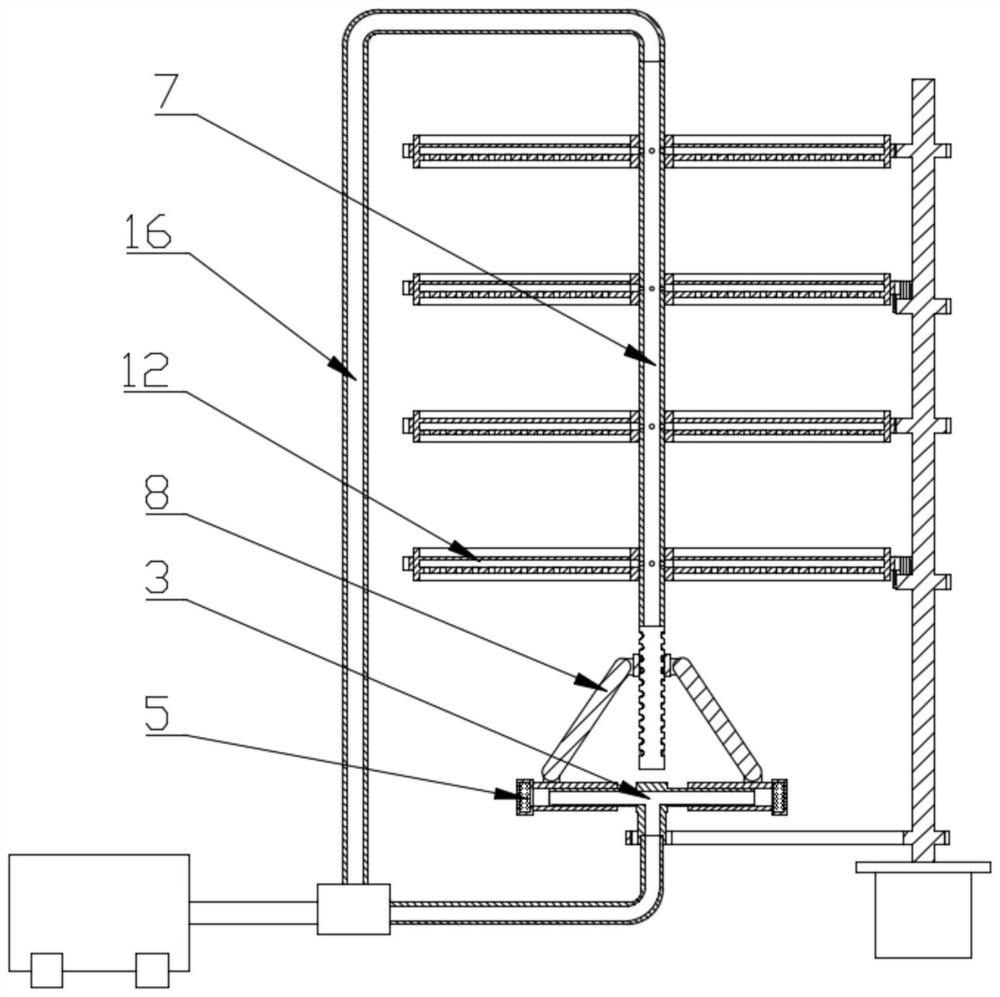

[0024] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0025] like Figure 1-4 As shown, an ultra-micro nano-bubble aeration device includes a cylinder body 1 and an air compressor 2, the bottom of the cylinder body 1 is rotatably connected with a T-shaped rod 3, and the T-shaped rod 3 is hollow, and the Both ends of the T-shaped rod 3 are slidably connected with a sleeve 4, one end of the sleeve 4 is installed with an aeration head 5, the bottom end of the T-shaped rod 3 is rotatably connected with the cylinder body 1, and the T-shaped rod 3 The first pipe 6 communicates with the air compressor 2 , the cylinder body 1 is provided with a driving device for driving the T-shaped rod 3 to rotate, and the sleeve 4 is equipped with a sleeve 4 that makes the T-shaped rod 3 rotate when the T-shaped rod 3 rotates. A motion component that performs piston movement on the T-bar 3.

[0026] In this specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com