Assembly type combined steel bridge

A prefabricated, steel bridge technology, applied in the direction of bridges, truss bridges, bridge parts, etc., can solve the problems of large deflection, large span, insufficient span, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0055] This embodiment provides a prefabricated combined steel bridge, which has the advantages of small deflection and large span, and can solve the problems of large deflection and insufficient span of prefabricated highway steel bridges in the prior art.

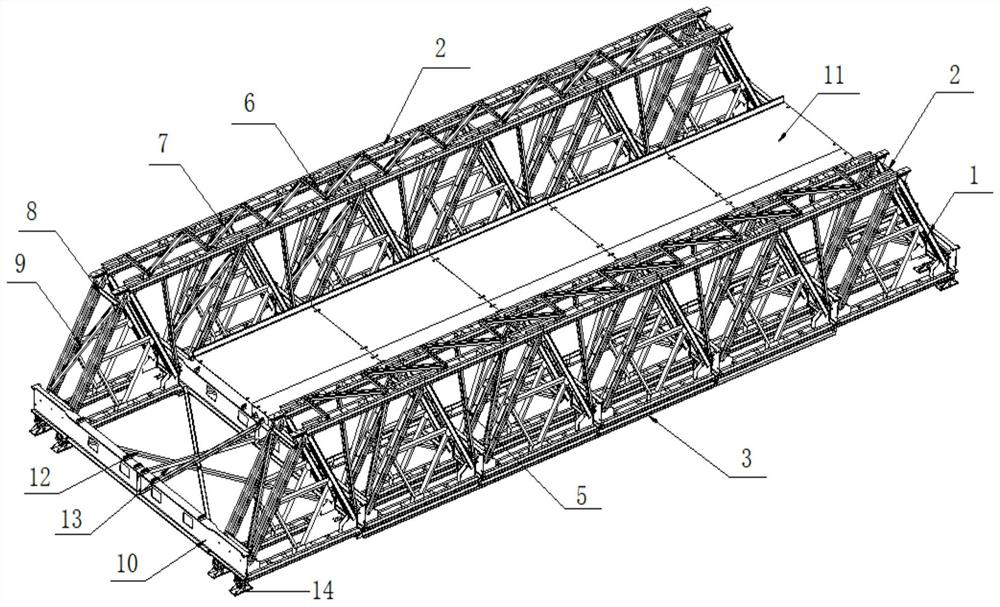

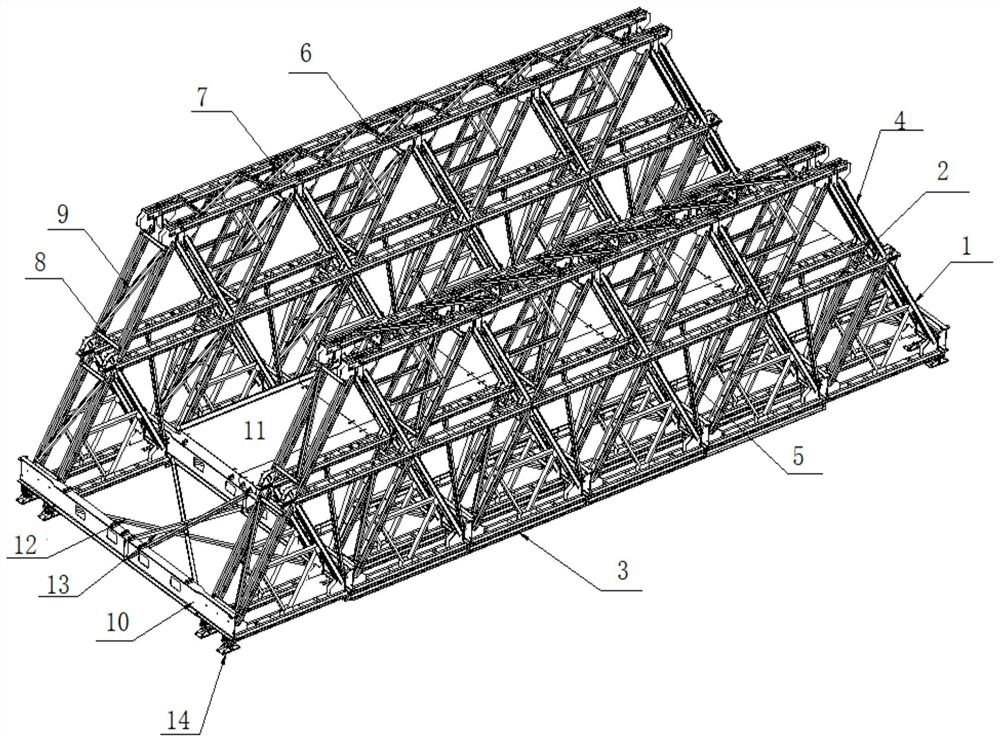

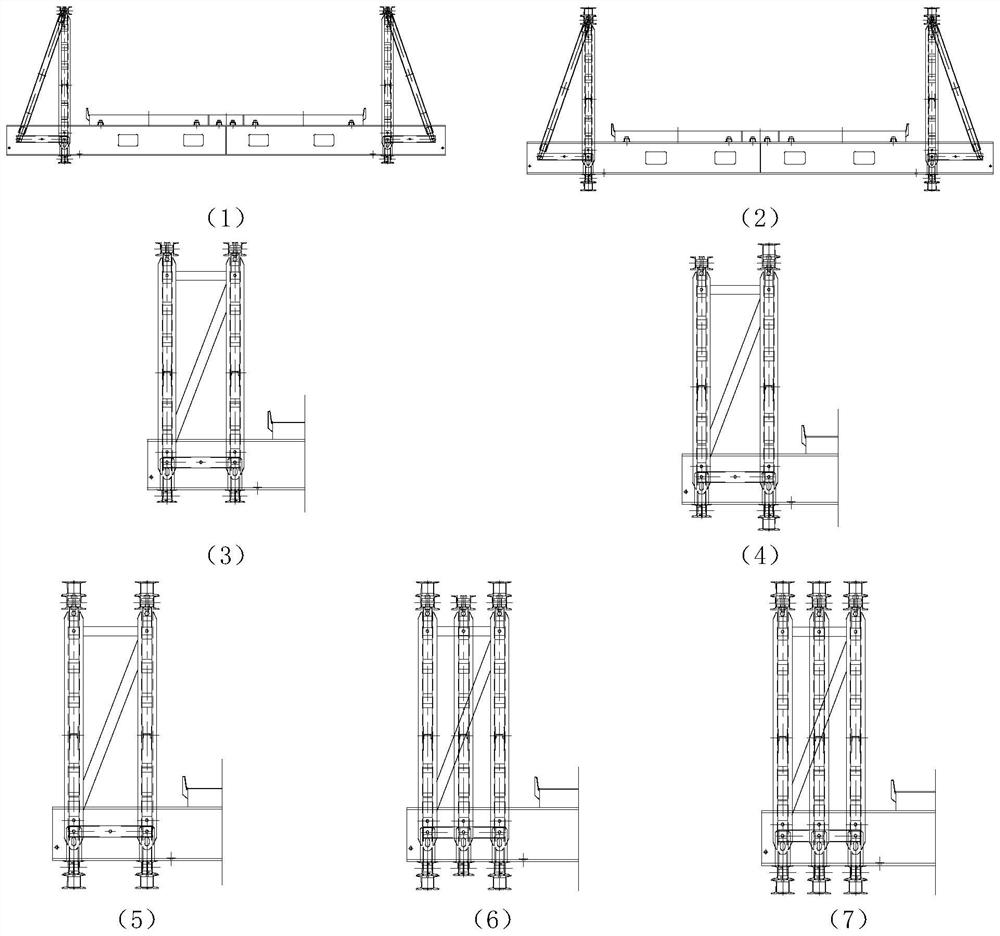

[0056] Such as figure 1 and figure 2 As shown, the combined steel bridge includes: four abutments 14, two longitudinal girders, a bridge deck 11, more than two beams 10, more than one pair of wind-resistant pull bars 12 and more than one vertical wind structure 13; wherein, each A longitudinal girder includes more than one row of truss units; bridge deck 11 includes more than one sub-deck, such as Figure 20 As shown, the sub-bridges are divided into side bridges, standard bridges and middle bridges;

[0057] Such as Figure 8 As shown, each row of truss units includes: triangular truss 1 and sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com