Slow-closing type check valve with low flow resistance

A slow-closing, check valve technology, applied to valve details, control valves, valve devices, etc., can solve problems such as large shock waves, noise, and water hammer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

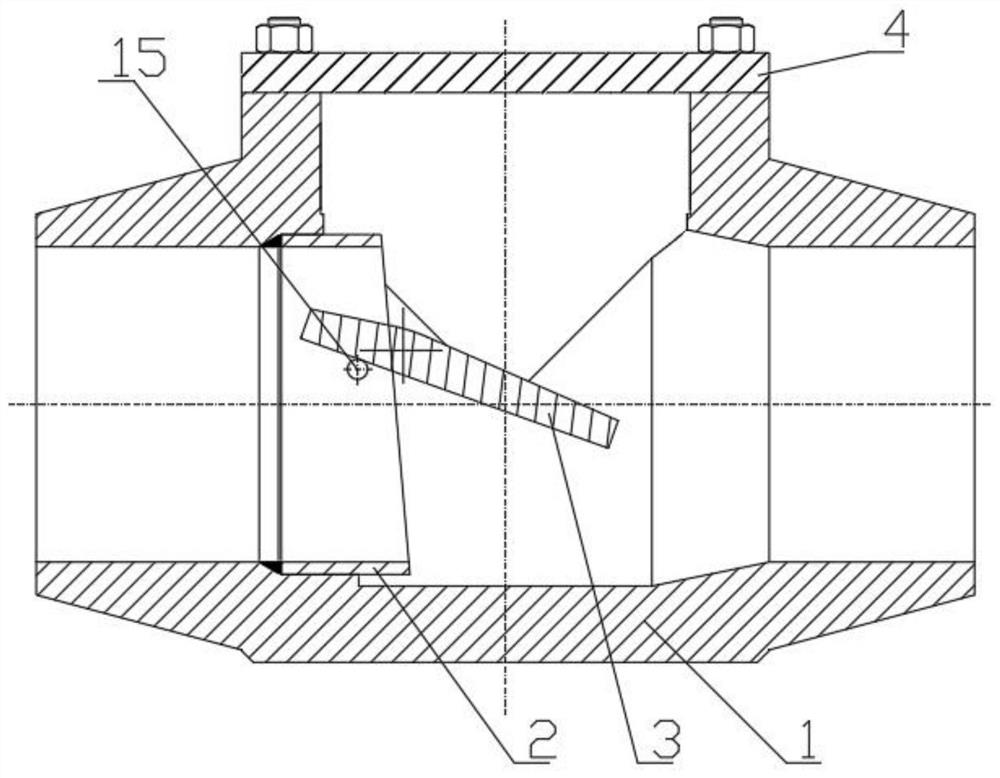

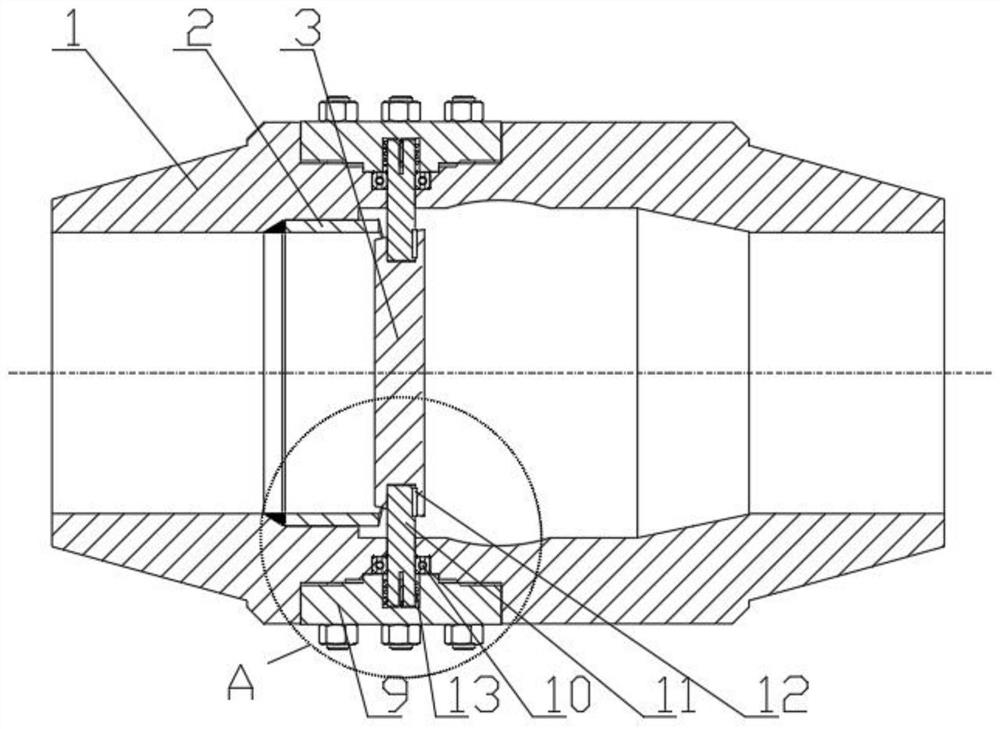

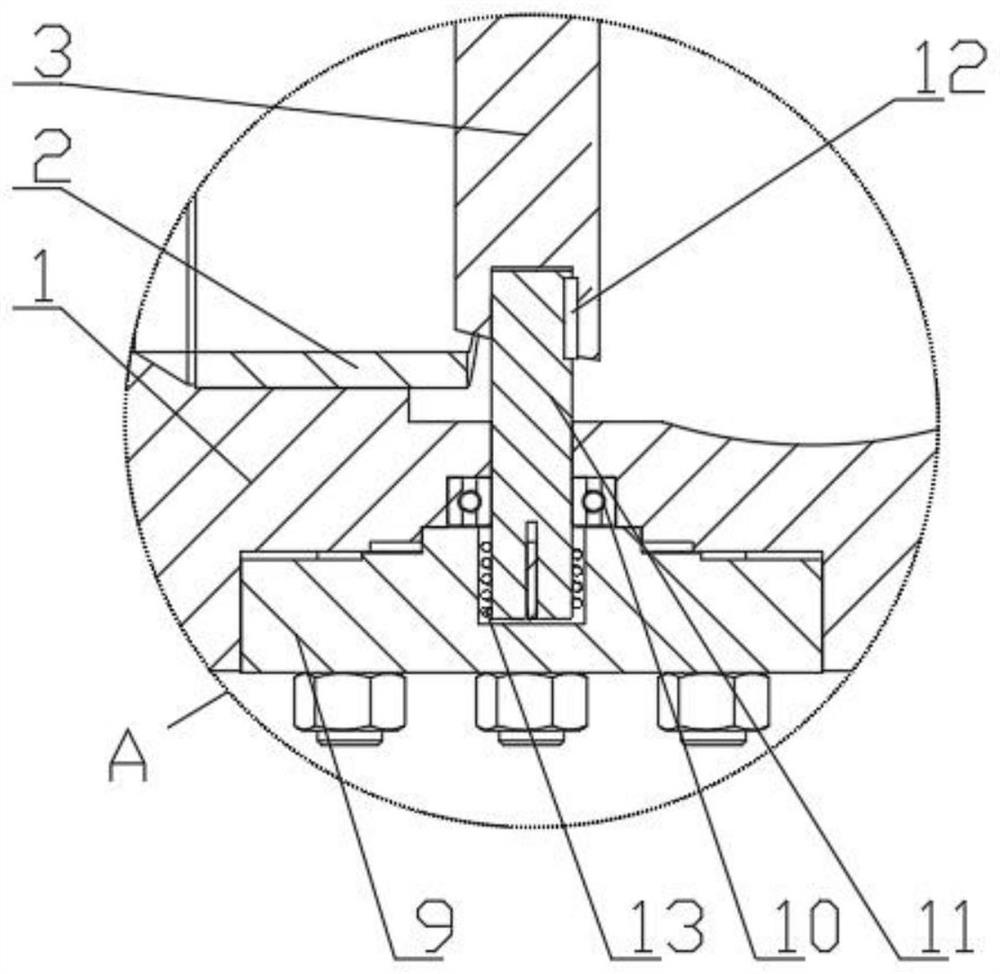

[0026] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, a slow-closing check valve with low flow resistance in this embodiment, including a valve body 1, a valve seat 2, a valve flap 3, an end cover 9, a rotating shaft 11 and a torsion spring 13, the inlet of the valve body 1 A valve seat 2 is installed on the side, and an end cover 9 is installed on the side of the valve body 1. One end of the torsion spring 13 is connected to the shaft end of the rotating shaft 11, and the other end of the torsion spring 13 is connected to the end cover 9. The valve body 1 is connected, and the torsion spring 13 prevents the valve clack from beating the sealing surface, thereby affecting the sealing performance.

specific Embodiment approach 2

[0027] Specific implementation mode two: Combining figure- Figure 4 Describe this embodiment. A slow-closing check valve with low flow resistance in this embodiment also includes a bearing 10 and a key 12. The rotating shaft 11 is connected to the valve body 1 through the bearing 10. The rotating shaft 11 is eccentric to the disc 3 through the key 12. The positions are connected, and when the medium flows backward, because the upstream and downstream areas of the valve disc 3 located on the rotating shaft 11 are different, the medium pushes the valve disc 3 to generate a closing rotational moment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 1-Figure 4 This embodiment is described. In the low flow resistance slow-closing check valve of this embodiment, there are two end caps 9 , and the two end caps 9 are symmetrically installed on both sides of the valve body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com