Flexible temperature equalizing plate

A vapor chamber, flexible technology, used in electrical equipment structural parts, lighting and heating equipment, cooling/ventilation/heating retrofits, etc., can solve problems such as lack of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following examples are provided to describe the present invention in detail, and the examples are only used as examples for illustration and will not limit the scope of protection of the present invention. In addition, the drawings in the embodiments omit elements that are not necessary or can be completed by common techniques, so as to clearly show the technical characteristics of the present invention.

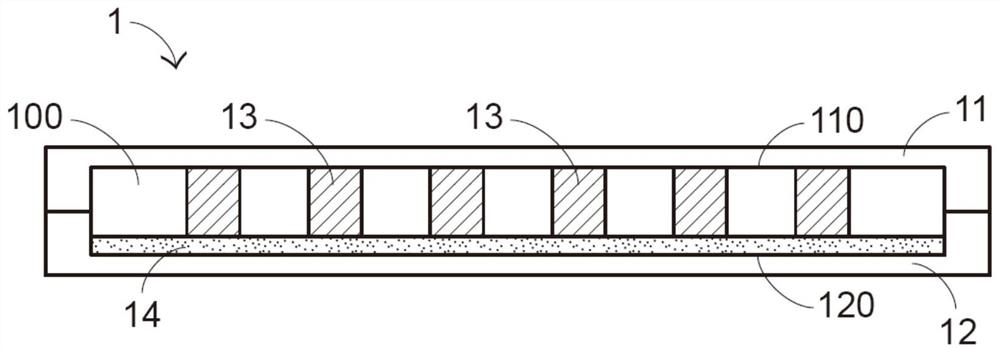

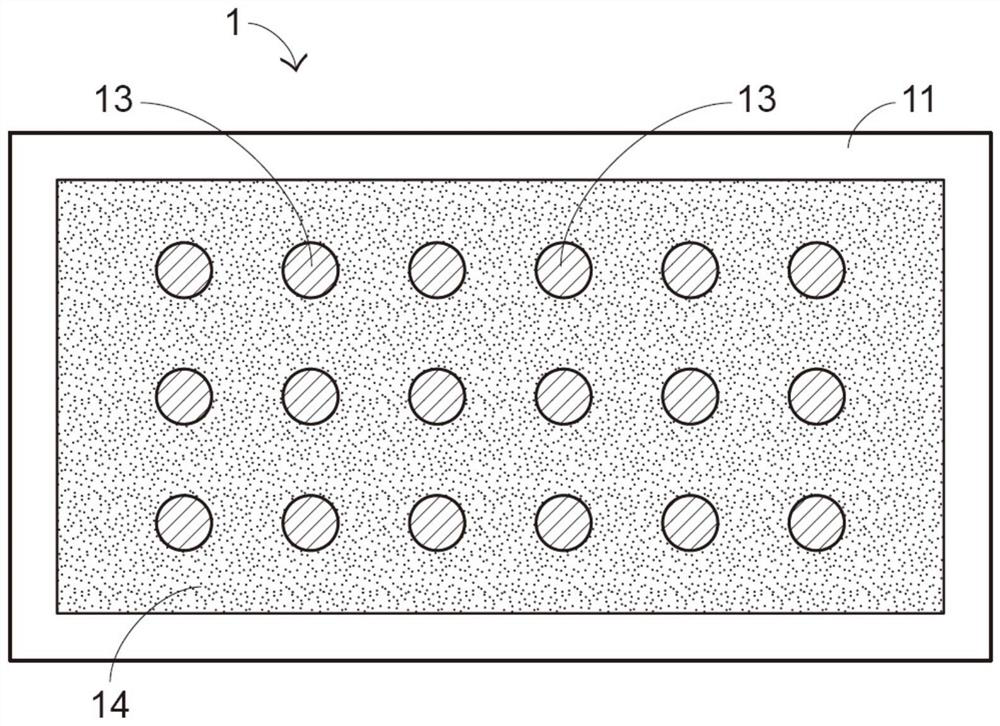

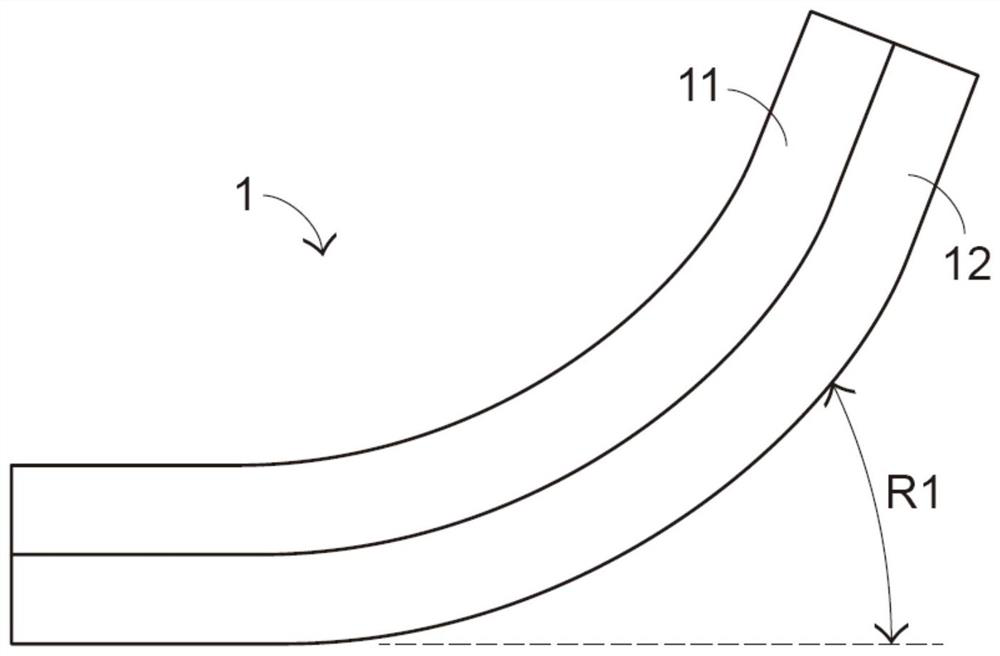

[0038] The implementation description of the present invention is now carried out with a first embodiment. See also Figure 1A and Figure 1B . in Figure 1A It is a longitudinal sectional view of a vapor chamber 1 proposed in the first embodiment; Figure 1B It is a cross-sectional view of the chamber 1 . Such as Figure 1A and Figure 1B As shown, the vapor chamber 1 mainly includes an upper cover 11 , a lower cover 12 and a working fluid (not shown in the drawing). The upper cover 11 is disposed on the lower cover 12 , and a chamber 100 is formed therebetw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com