Method for determining volume hydrogen content in high-purity aluminum or high-purity aluminum alloy

A technology of aluminum alloy and hydrogen content, which is applied in the direction of measuring devices, test sample preparation, sampling, etc., can solve the problems of hydrogen and other impurity gas precipitation, low hydrogen content, and no consideration of surface hydrogen interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

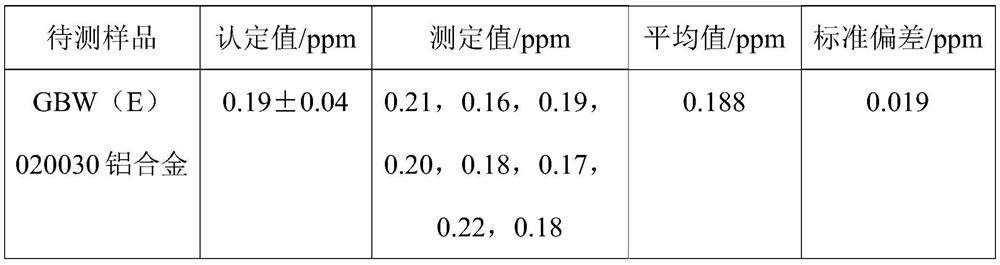

[0063] This example provides a method for measuring the volumetric hydrogen content in high-purity aluminum or high-purity aluminum alloys. The GBW(E)020030 aluminum alloy (brand 7B04) developed by Beijing Aeronautical Materials Institute is selected as the sample to be tested, and its volume is known. Hydrogen content is (0.19 ± 0.04) ppm, with this the accuracy of verification method, described method comprises the following steps:

[0064] (1) The sample to be tested is divided into sample A to be tested and sample B to be tested by turning, and then pre-treated respectively and put into sherwood oil for use;

[0065] Wherein, the pretreatment includes sample preparation and cleaning; the sample preparation is to machine the sample A and the sample B to be tested into a cylindrical shape with a diameter of 5 mm and a height of 24 mm by turning; The cleaning is to place the test sample A or test sample B obtained by the sample preparation in carbon tetrachloride for ultrason...

Embodiment 2

[0082] This embodiment provides a method for measuring the volume hydrogen content in high-purity aluminum or high-purity aluminum alloy. A high-purity aluminum ingot is selected as the sample to be tested, and the volume hydrogen content is about 0.15-0.2ppm. The method includes the following step:

[0083] (1) The sample to be tested is divided into sample A to be tested and sample B to be tested by turning, and then pre-treated respectively and put into sherwood oil for use;

[0084] Wherein, the pretreatment includes sample preparation and cleaning; the sample preparation is to machine the sample A and the sample B to be tested into a cylindrical shape with a diameter of 6 mm and a height of 25 mm by turning; The cleaning is to place the test sample A or test sample B obtained by the sample preparation in carbon tetrachloride for ultrasonication, the power of the ultrasonic wave is 120W, the frequency is 50kHz, and the time is 4min;

[0085] (2) Weigh the mass m of the sa...

Embodiment 3

[0101] This embodiment provides a method for measuring the volume hydrogen content in high-purity aluminum or high-purity aluminum alloy. A high-purity aluminum ingot is selected as the sample to be tested, and the volume hydrogen content is about 0.15-0.2ppm. The method includes the following step:

[0102] (1) The sample to be tested is divided into sample A to be tested and sample B to be tested by turning, and then pre-treated respectively and put into sherwood oil for use;

[0103] Wherein, the pretreatment includes sample preparation and cleaning; the sample preparation is to machine the sample A and the sample B to be tested into a cylindrical shape with a diameter of 5 mm and a height of 20 mm by turning; The cleaning is to place the sample to be tested A or the sample to be tested B obtained by the sample preparation in carbon tetrachloride for ultrasonication, the power of the ultrasonic wave is 100W, the frequency is 40kHz, and the time is 5min;

[0104] (2) Weigh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com