Method for detecting elemental phosphorus content in industrial wastewater

A detection method and technology for industrial wastewater, applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problems of technical defects, long time, loss of elemental phosphorus, etc., Achieve the effect of small blank value, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

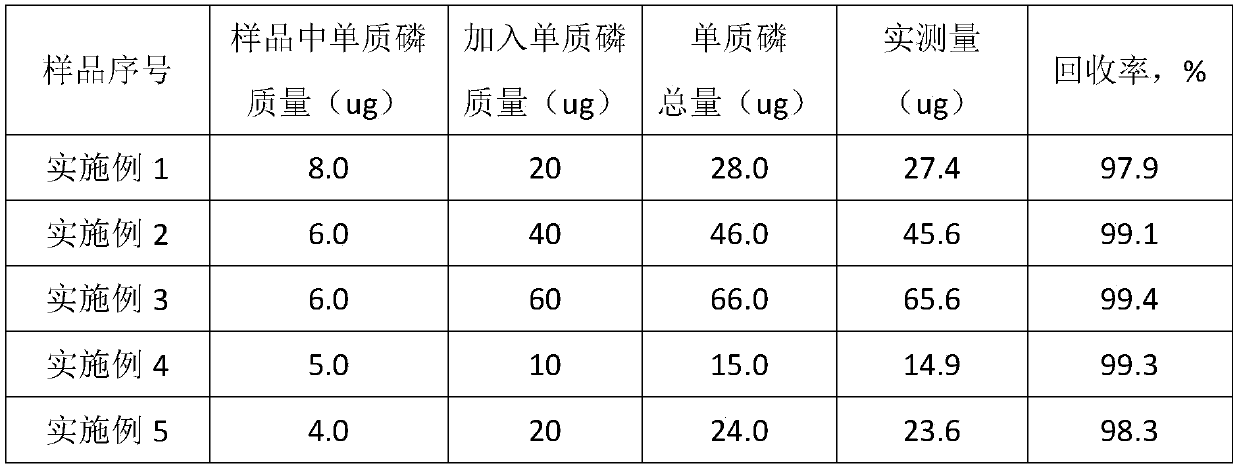

Embodiment 1

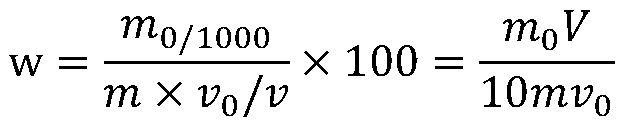

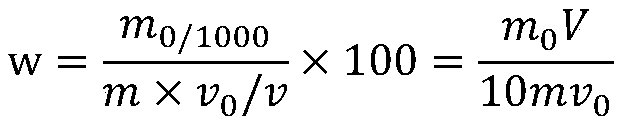

[0042] Extraction: Take 10g sample (known to contain 8ug elemental phosphorus), put it in a 500mL separatory funnel filled with 15ml benzene, add about 200mL water, cover tightly, shake for 2 minutes, and discard the water after standing for stratification phase, then add 200mL of water, repeat the operation until there are no chloride ions and phosphate ions in the water phase (take 5mL of the water phase in a 5mL beaker, add 1 drop of 1mol / L silver nitrate solution, no white precipitate or turbidity Yes, if yes, continue to repeat).

[0043] Test: Put the extracted benzene solution in a 25mL volumetric flask, add 1ml phosphorus standard solution (concentration 0.02mg / ml), 4.0mL anhydrous methanol, dilute to the mark with benzene, and shake well. Add 1 drop of silver nitrate solution, shake vigorously for 10 seconds, stand still for 8 minutes, at 520nm, use a 1cm cuvette, adjust the zero point of the spectrophotometer with the standard colorimetric solution added with 0.0mL p...

Embodiment 2

[0046] Extraction: Take 8g of sample (known to contain 6ug elemental phosphorus), put it in a 500mL separatory funnel filled with 15ml of benzene, add about 200mL of water, cover tightly, shake for 2 minutes, and discard the water after standing for stratification phase, then add 200mL of water, repeat the operation until there are no chloride ions and phosphate ions in the water phase (take 5mL of the water phase in a 5mL beaker, add 1 drop of 1mol / L silver nitrate solution, no white precipitate or turbidity Yes, if yes, continue to repeat).

[0047]Test: Put the extracted benzene solution in a 25mL volumetric flask, add 2ml phosphorus standard solution (concentration 0.02mg / ml), 4.0mL anhydrous methanol, dilute to the mark with benzene, and shake well. Add 1 drop of silver nitrate solution, shake vigorously for 10 seconds, stand still for 8 minutes, at 520nm, use a 1cm cuvette, adjust the zero point of the spectrophotometer with the standard colorimetric solution added with ...

Embodiment 3

[0050] Extraction: Take 8g of sample (known to contain 6ug elemental phosphorus), put it in a 500mL separatory funnel filled with 15ml of benzene, add about 200mL of water, cover tightly, shake for 2 minutes, and discard the water after standing for stratification phase, then add 200mL of water, repeat the operation until there are no chloride ions and phosphate ions in the water phase (take 5mL of the water phase in a 5mL beaker, add 1 drop of 1mol / L silver nitrate solution, no white precipitate or turbidity Yes, if yes, continue to repeat).

[0051] Test: Put the extracted benzene solution in a 25mL volumetric flask, add 3ml phosphorus standard solution (concentration 0.02mg / ml), 4.0mL anhydrous methanol, dilute to the mark with benzene, and shake well. Add 1 drop of silver nitrate solution, shake vigorously for 10 seconds, stand still for 8 minutes, at 520nm, use a 1cm cuvette, adjust the zero point of the spectrophotometer with the standard colorimetric solution added with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com