Probe unit, probe bed structure and lithium battery detection and formation equipment

A probe unit and probe technology, applied in secondary battery testing, secondary battery repair/maintenance, electrical measuring instrument components, etc., can solve the problem of low lithium battery testing efficiency, inability to improve lithium battery testing efficiency, battery Problems such as batch detection cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

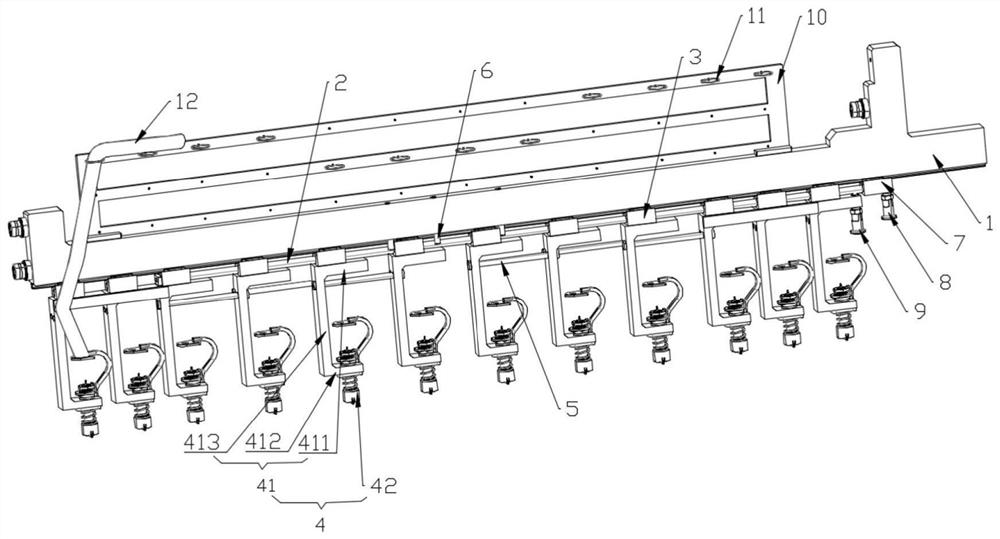

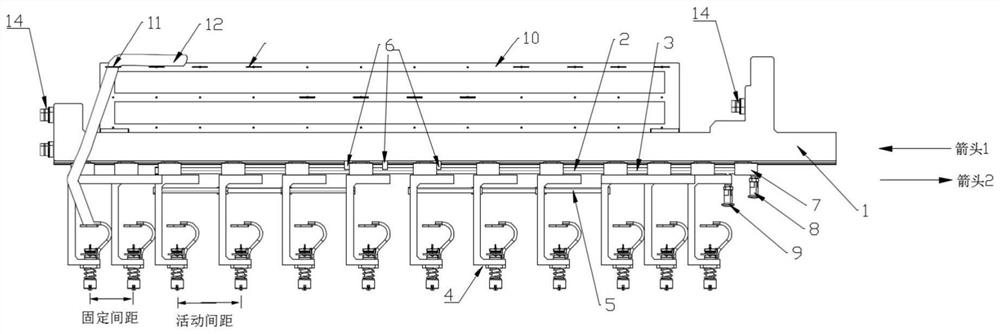

[0036] refer to figure 1 , figure 2 As shown, this embodiment provides a probe unit, which specifically includes a fixed base 1 and a probe module 4; wherein the lower edge of the fixed base 1 is provided with a slide rail, and a plurality of sequential Side-by-side slide blocks 3; and a push rod 2 is provided below the fixed base 1, wherein the push rod 2 and the lower edge of the fixed base 1 are parallel to each other along the line, and the push rod 2 runs through a plurality of slide blocks 3, so that the push rod 2 can be pushed A plurality of sliders 3 are driven to move synchronously along the push rod 2 .

[0037] And all be provided with probe module 4 on each slide block 3, probe module 4 comprises connection block 41 and probe 42, the top of connection block 41 links to each other with slide block 3, and the bottom of connection block 41 connects probe. needle 42 so that the detection port of the probe 42 faces downward. In this embodiment, the connection block...

Embodiment 2

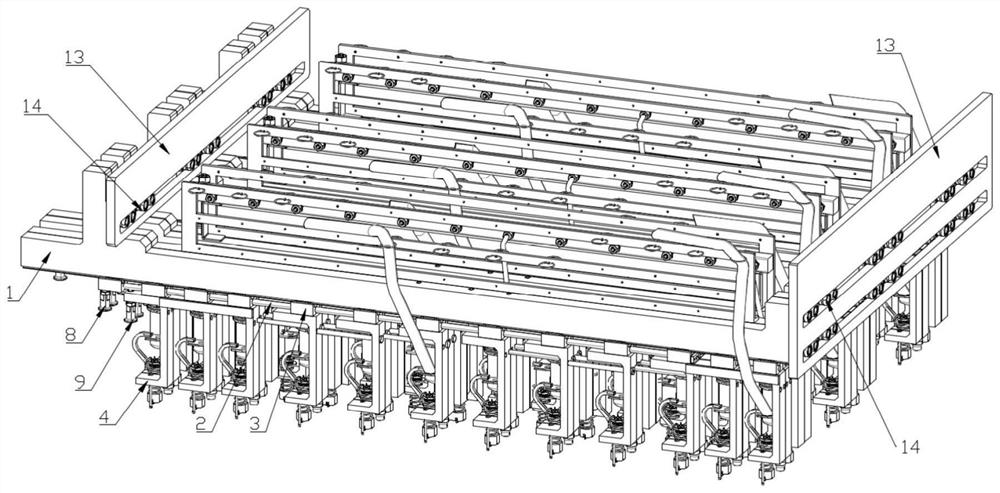

[0048] This embodiment provides a needle bed structure, which is formed by combining a plurality of probe units described in Embodiment 1, such as image 3 As shown, the needle bed structure includes a positioning bracket 13 and a plurality of probe units as in Embodiment 1, and the left and right ends of the fixed base 1 of each probe unit are provided with fixing components 14, and multiple probes After the unit is placed on the positioning bracket 13, each probe unit is connected to the left and right sides of the positioning bracket 13 by its fixing component 14, so that multiple probe units are installed side by side on the positioning bracket 13 to form a needle bed structure.

[0049] In this embodiment, in order to avoid the different heights of multiple probe units, slots are provided on the left and right sides of the positioning bracket 13, and the fixing assembly 14 is a slot corresponding to the slot, and the fixing assembly 14 is snapped into the Fix the two wit...

Embodiment 3

[0051] This embodiment provides a lithium battery detection and formation equipment, which applies the needle bed structure in the second embodiment to the lithium battery formation equipment, so as to realize rapid and accurate batch detection of lithium batteries of different battery specifications and improve detection efficiency.

[0052] Such as image 3 As shown, the lithium battery detection and formation equipment of this embodiment includes a detection platform 15 , a needle bed structure as described in Embodiment 2, and a pressing device 16 . The detection platform 15 is provided with a plurality of storage positions, and each storage position can correspond to a lithium battery. After the lithium battery is placed on the storage position, the power supply can be automatically calibrated; The needle bed structure described above makes the probe 42 on the needle bed structure face the detection platform 15; while the pressing device 16 in the lithium battery detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com