Magnetic stripe and coil assembly structure and cooking equipment

A technology for assembling structure and cooking equipment, which can be applied to coil devices, induction heating, etc., and can solve problems such as insufficient heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

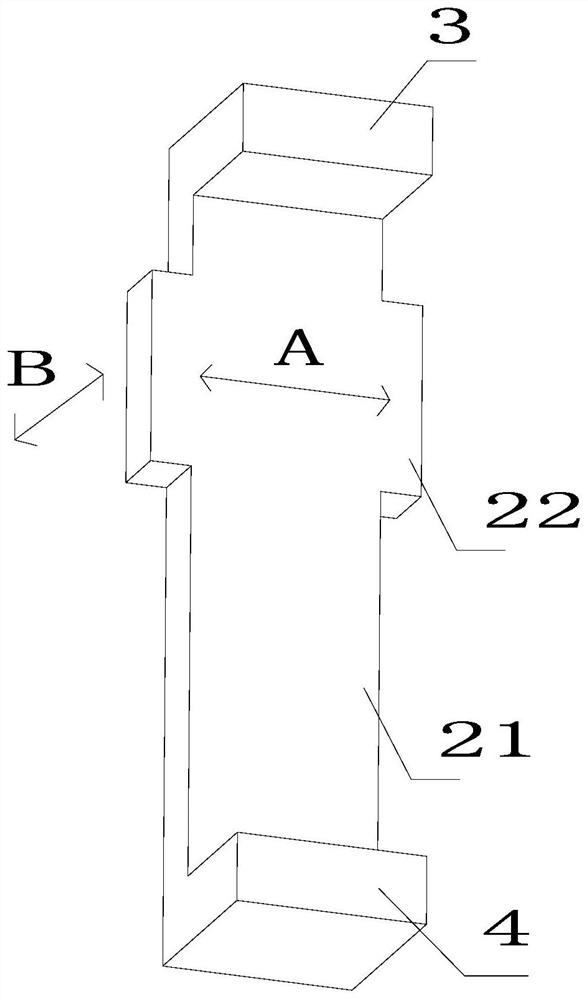

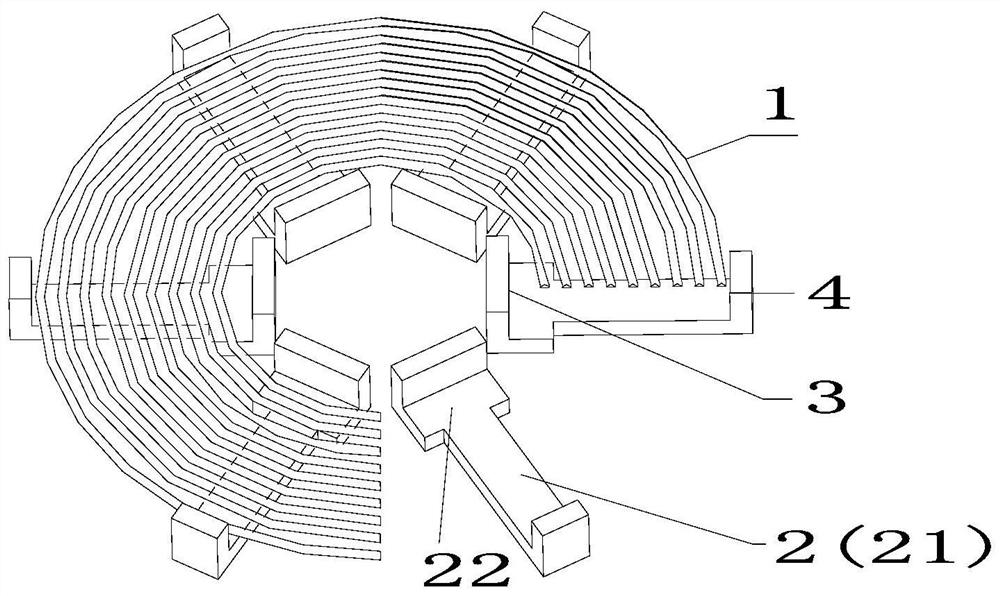

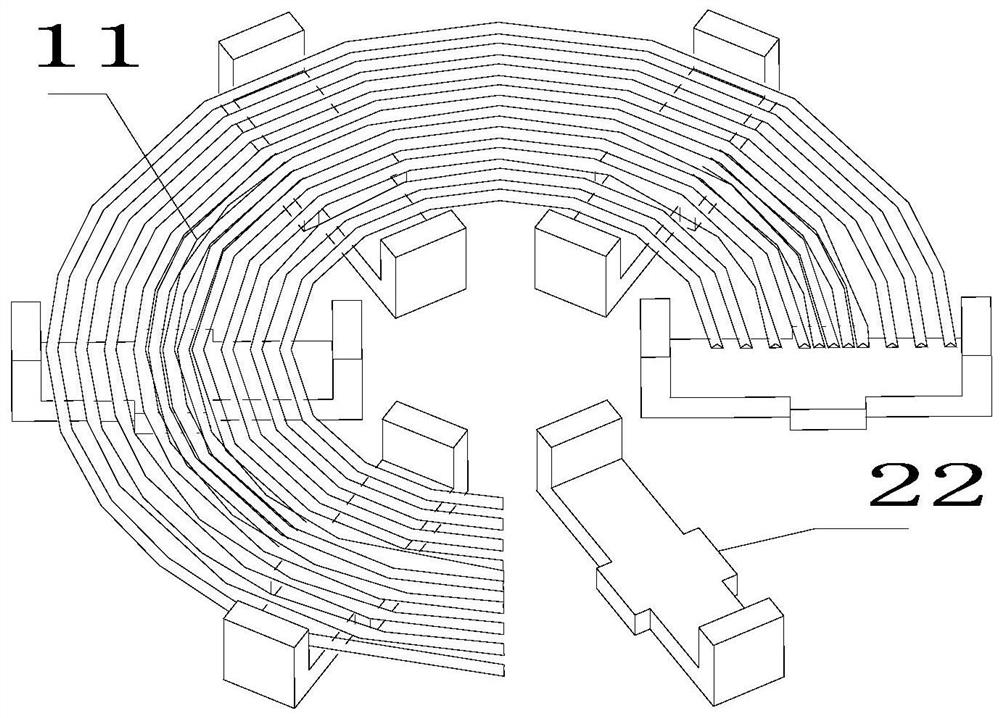

[0039] This embodiment provides an assembly structure of the magnetic strip 2 and the coil 1, such as Figure 1-Figure 5 shown, including:

[0040] Coil 1, the coil 1 includes a wire-dense area 11 and a wire-loose area; specifically, the coil 1 itself can be a disk-shaped structure, or can be in other shapes, such as a rectangular arrangement. The coil 1 is provided with an incoming line interface and an outgoing line interface, the current flows into the coil 1 through the incoming line interface, and flows out of the coil 1 through the outgoing line interface;

[0041] The magnetic strip 2 is detachably arranged on the coil 1, the magnetic strip 2 has a magnetic strip strengthening area 22 corresponding to the wire dense area 11, and a magnetic strip 2 corresponding to the wire loose area zone of weakening.

[0042] By setting the magnetic strip strengthening area 22, the wire dense area 11 on the coil 1 can obtain more magnetic flux density, and at the same time, because ...

Embodiment 2

[0054] This embodiment provides a cooking device, including the assembly structure of the magnetic strip and the coil provided in Embodiment 1, and a pot body. The coil itself is arranged below the pot body and can support the pot body in a pocket shape.

[0055] In this embodiment, the cooking device may be an electrical device such as an electric pressure cooker that requires the cooperation of a coil and a magnetic strip for heating. As a preferred embodiment, the cooking device is an electric rice cooker.

[0056] In the cooking equipment provided in this embodiment, since the wire-intensive area on the coil 1 is correspondingly arranged in the magnetic strip reinforcement area, more magnetic flux density can be obtained at the wire-intensive area, thereby making the pot body have a larger Magnetic flux, so as to achieve better heating effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com