fire sprinkler equipment

A spraying equipment and fire-fighting technology, which is applied in fire rescue and other directions, can solve the problems of small spraying area, insufficient uniformity of water, general fire-extinguishing effect of spraying equipment, etc., and achieve the goal of improving uniformity, spraying area and uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

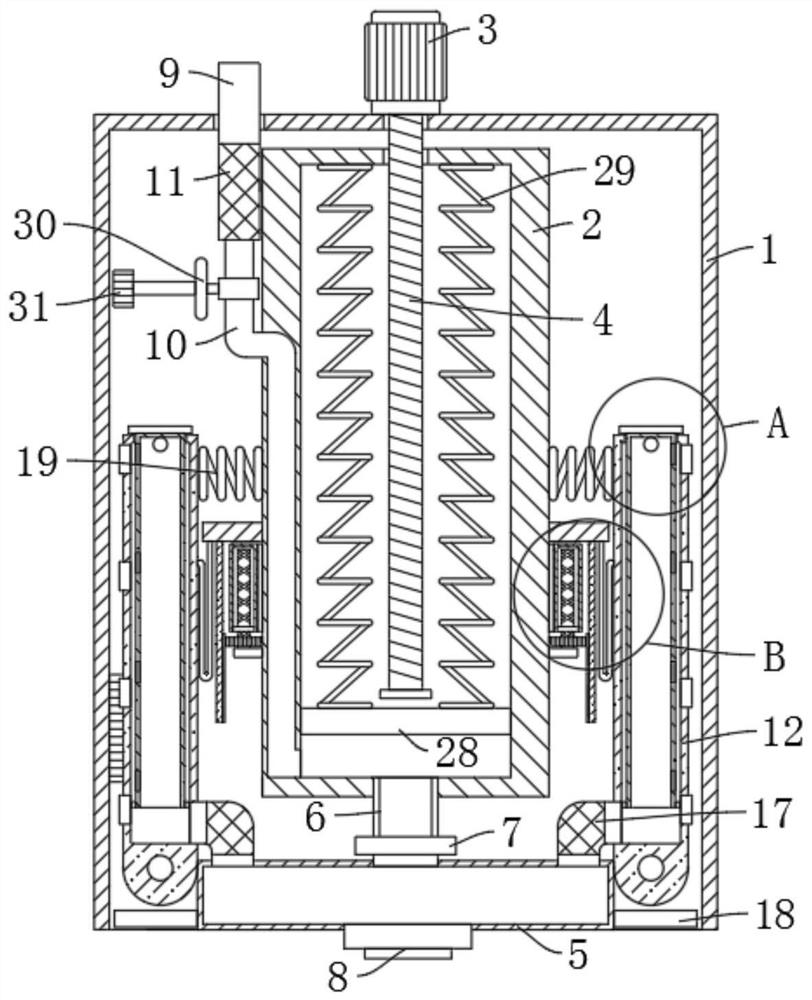

[0031] refer to Figure 1-4 , a sprinkler equipment for fire-fighting, comprising a casing 1 with an opening downward, a water storage tank 2 is arranged inside the casing 1, a driving motor 3 is fixedly installed on the upper end of the casing 1, and the output end of the driving motor 3 is fixedly connected with Extending to the threaded rod 4 inside the casing 1, the threaded rod 4 is threadedly connected to the upper end of the water storage tank 2, the lower end of the water storage tank 2 is provided with an output pipe 6, and the lower end of the output pipe 6 is rotatably connected with a hollow disc 5 communicating with it, The lower end of the hollow disc 5 is fixedly equipped with a first nozzle 8, the upper end of the casing 1 is fixedly connected with a water inlet pipe 9, and the lower end of the water inlet pipe 9 extends into the casing 1 and is fixedly connected with a first telescopic hose 11. The lower end of the flexible pipe 11 is fixedly connected and com...

Embodiment 2

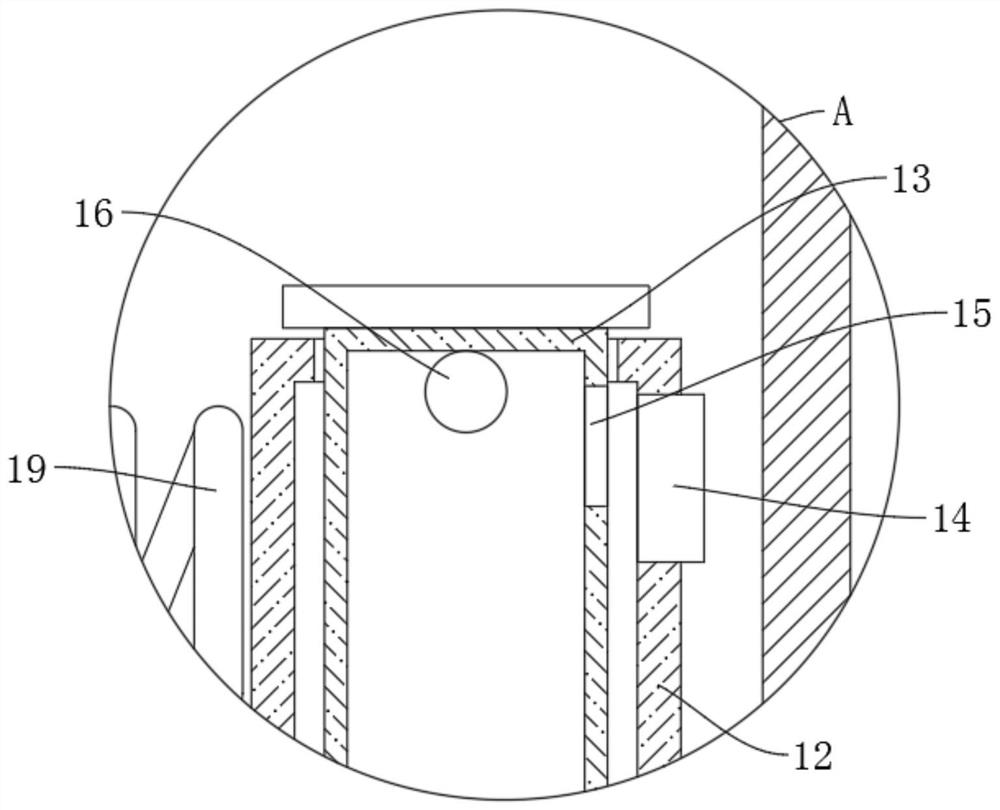

[0036] refer to figure 1 and figure 2 , is basically the same as Embodiment 1, furthermore: the rotary water spray device includes a plurality of first water spray pipes 12 that are rotatably connected to the outer wall of the hollow disc 5 circumferences, and the side walls of the multiple first water spray pipes 12 are all fixed A plurality of linearly distributed second nozzles 14 are installed, and the side walls of a plurality of first water spray pipes 12 are fixedly equipped with a third nozzle 16, and the injection directions of the third nozzle 16 and the second nozzle 14 are perpendicular to each other, and the hollow disc The lower end side wall of 5 is fixedly connected with the limiting plate 18, and the first water spray pipe 12 is fixedly connected with the hollow disc 5 through the second telescopic hose 17. Between the first water spray pipe 12 and the outer wall of the water storage tank 2 An up and down swing device is provided between them. When the water...

Embodiment 3

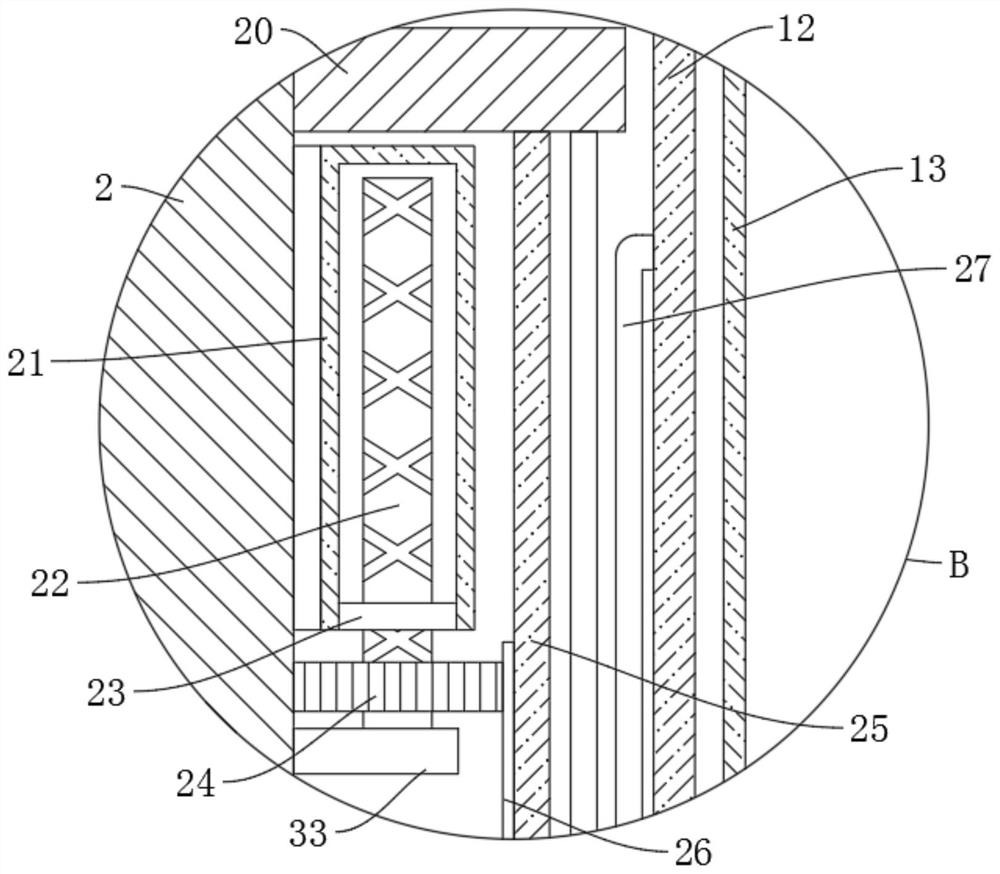

[0039] refer to figure 1 and image 3 , is basically the same as Embodiment 1, furthermore: the up and down swing device includes a sleeve 21 that is slidably connected to the outer wall of the water storage tank 2, the inner sleeve of the sleeve 21 is provided with a reciprocating screw 22, and the lower end of the reciprocating screw 22 on the outer wall The lead screw slider 23 matched with it is sleeved, the lead screw slider 23 is fixedly connected to the inner wall of the sleeve 21, the lower end of the reciprocating lead screw 22 is fixedly connected with a pinion 24, and the lower end of the reciprocating lead screw 22 rotates through the support 33 Connected to the outer wall of the water storage tank 2, the outer wall of the water storage tank 2 is located at the upper end of the sleeve 21 and is slidingly sleeved with an annular plate 20, the lower end of the annular plate 20 is fixedly connected with a sleeve 25, and the inner wall of the sleeve 25 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com