Gyratory flywheel with rapid acceleration structure

An acceleration structure and flywheel technology, applied in the field of boomerangs, can solve problems such as inconvenient use, single function, and difficulty in achieving the effect of boomerang recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

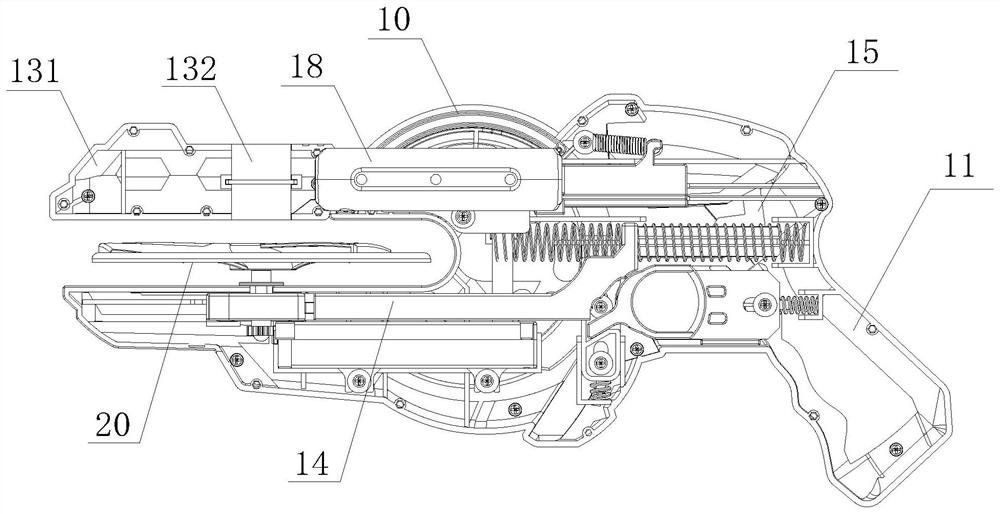

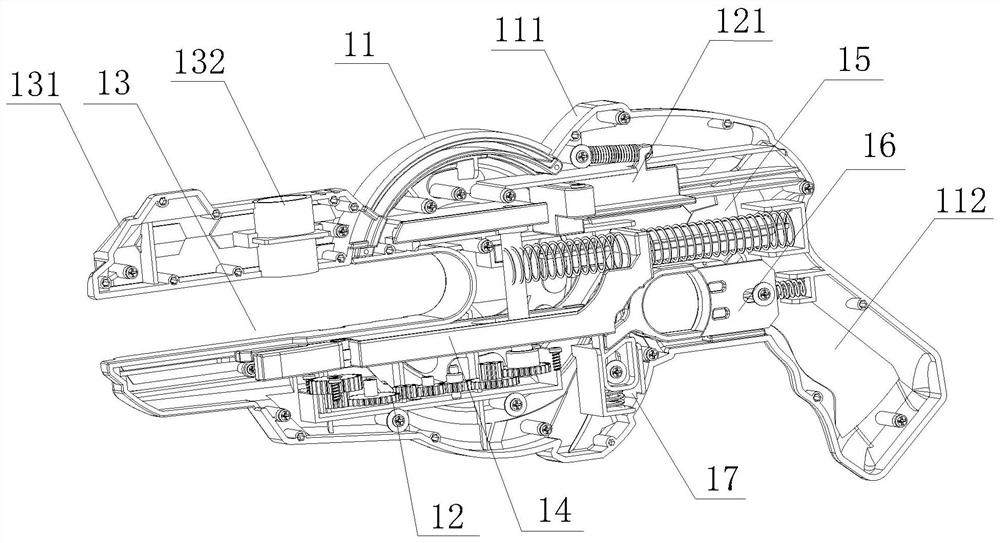

[0034] see Figure 1-7 , the present invention provides a technical solution: a spinning flywheel with a fast acceleration structure, including: a firing gun 10 and a spinning flywheel 20 .

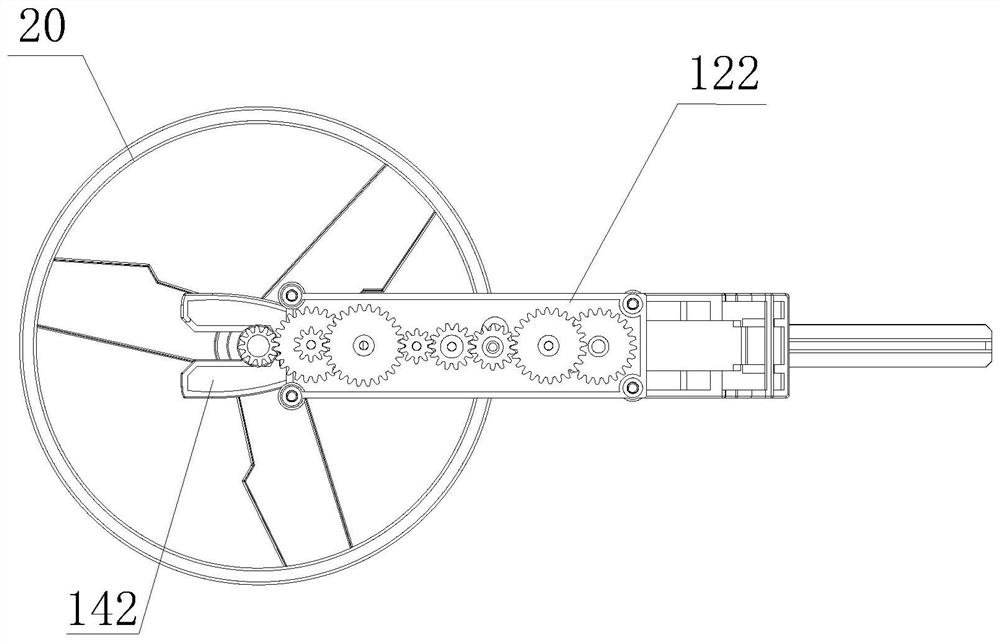

[0035] Wherein, the launch gun 10 includes a launch gun casing 11, an acceleration assembly 12 and a launch mechanism 14, the acceleration assembly 12 includes a pull tooth 121, a gear box 122 and a conversion main shaft 124, and the inside of the gear box 122 is installed by rotating a rotating shaft. In the transmission gear assembly 123 , the upper and lower ends of the conversion main shaft 124 are fixedly equipped with main shaft gears 125 , and the conversion main shaft 124 is meshed with the pull teeth 121 .

[0036] Further, the pulling stroke of the pulling tooth 121 is about 45mm.

[0037] Further, pulling the pulling tooth 121 drives the conversion main shaft 124 to rotate, and accelerates the main shaft gear 125 to rotate. The main shaft gear 125 realizes a super large speed ...

Embodiment 2

[0057] see Figure 1-7 , the present invention provides a technical solution: a spinning flywheel with a fast acceleration structure, including: a firing gun 10 and a spinning flywheel 20 .

[0058] Wherein, the revolving flywheel 20 includes a flywheel hub 21 and flywheel blades 22, and the flywheel blades 22 are provided with several pieces, wherein several pieces of the flywheel blades 22 are fixedly installed on the inner wall surface of the flywheel hub 21, wherein several pieces of the flywheel blades 22 is fixedly connected with an acceleration shaft 24, and a hexagonal piece 23 is fixedly installed on the outside of the acceleration shaft 24 near the top end, and a flywheel body gear 26 is fixedly installed on the outside of the acceleration shaft 24 near the bottom end.

[0059] Further, pulling the pulling tooth 121 drives the conversion main shaft 124 to rotate, and accelerates the main shaft gear 125 to rotate. The main shaft gear 125 realizes a super large speed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com