Coating system and moisturizing device for coating structure thereof

A technology of moisturizing device and coating device, which is applied in the field of coating system, and can solve the problems of affecting the coating quality of coating colloid and blocking the glue outlet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

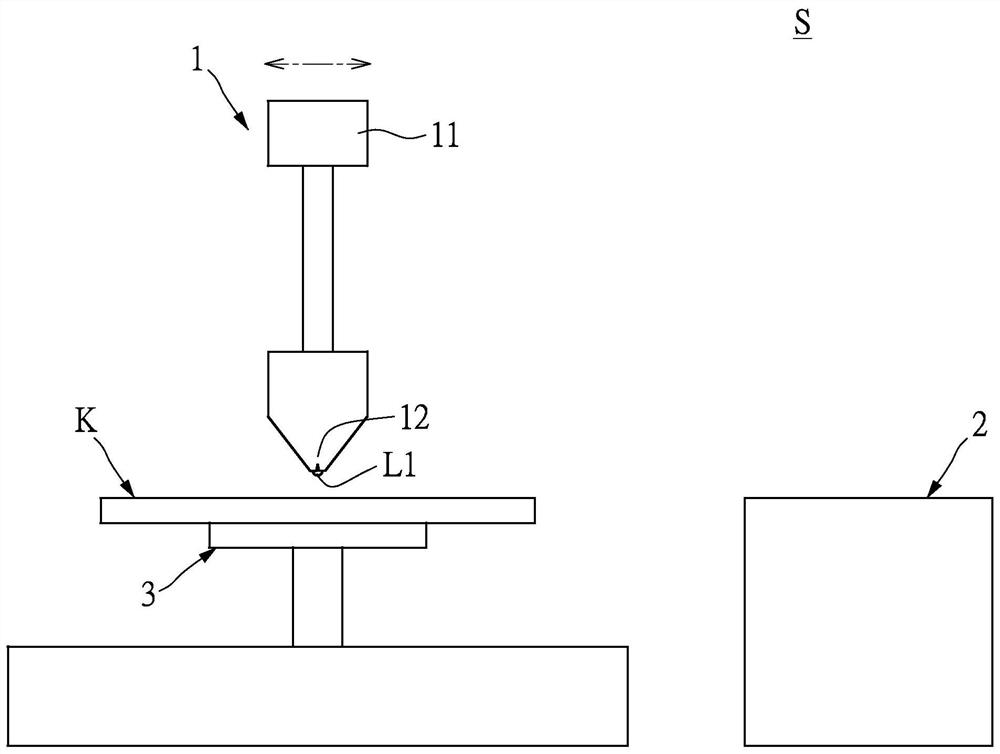

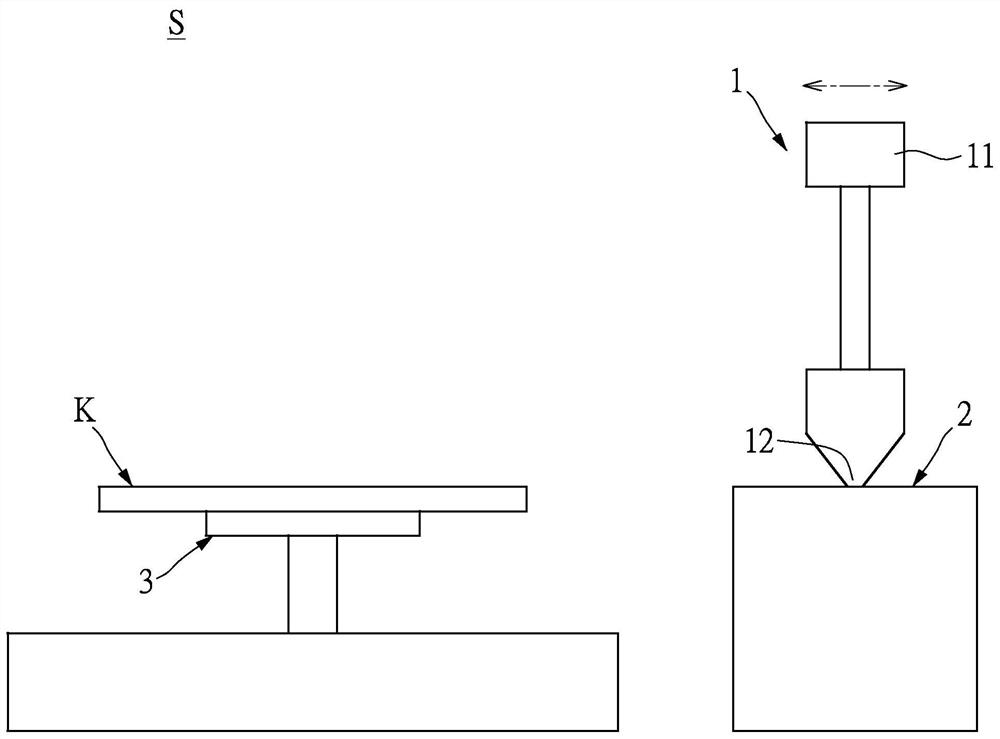

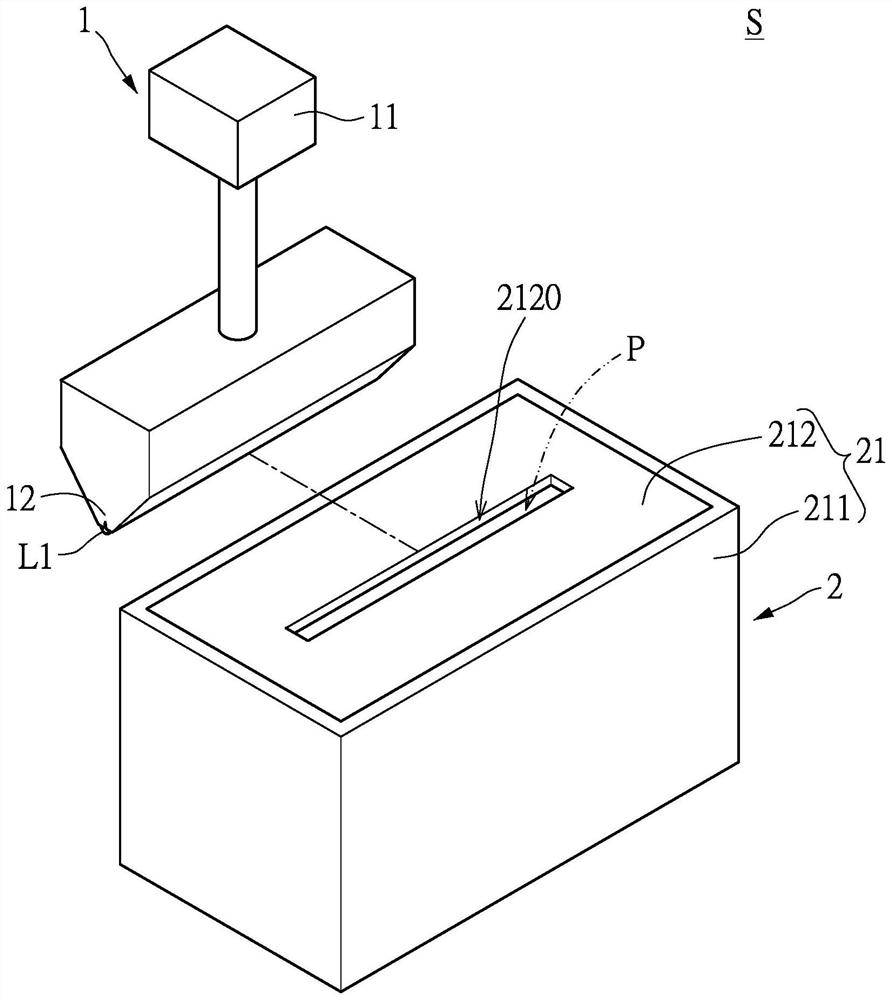

[0029] First, see figure 1 and figure 2 as shown, figure 1 and figure 2 They are schematic diagrams of the coating systems of the embodiments of the present invention, respectively. The present invention provides a moisturizing device 2 of a coating system S and a coating structure 12 thereof. For example, the moisturizing device 2 is preferably applied on the coating structure 12 for coating the highly volatile coating material L1, but the invention is not limited thereto. In other words, the moisturizing device 2 can also be applied in other systems, and the present invention is not limited to the application occasions of the moisturizing device 2 . It should be noted that the main structure of the coating system S will be described first, and the components of the moisturizing device 2 will be introduced later.

[0030] In view of the above, please refer to figure 1 and figure 2 As shown, the coating system S may include: a coating device 1 and a moisturizing devi...

no. 2 example

[0040] First, see Figure 7 and Figure 8 as shown, Figure 7 is a schematic cross-sectional view of a moisturizing device according to a second embodiment of the present invention, Figure 8 It is a functional block diagram of the moisturizing device according to the second embodiment of the present invention. Depend on Figure 7 and Figure 8 and Figure 6 Comparison shows that the biggest difference between the second embodiment and the first embodiment is that the moisturizing device 2 provided by the second embodiment can further include a sensing unit 23 , a liquid filling unit 24 and a control unit 25 . In this way, the sensing unit 23 can be used to detect the residual amount of the liquid L2 in the accommodating tank 21, and when the sensing unit 23 detects that the residual amount of the liquid L2 is lower than a preset threshold, the control unit 25 can output a consistent An activation signal is sent to the liquid filling unit 24 to fill the supplementary liq...

no. 3 example

[0044] First, see Figure 9 as shown, Figure 9 It is a schematic cross-sectional view of the moisturizing device according to the third embodiment of the present invention. Depend on Figure 9 and Figure 7 The comparison shows that the biggest difference between the third embodiment and the second embodiment is that the liquid filling unit 24 of the moisturizing device 2 provided by the third embodiment can be adjusted to the desired setting position according to the requirement. In the third embodiment, one end of the pipe 242 of the liquid filling unit 24 can be connected to the container 241 , the other end of the pipe 242 can pass through the cover 212 of the accommodating tank 21 , and the pipe 242 can pass through the liquid absorption unit 22 The first adsorption layer 221 and the second adsorption layer 222 are used to fill the supplementary liquid L3 in the accommodating space 210 . In addition, it should be noted that other structures of the coating system S an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com