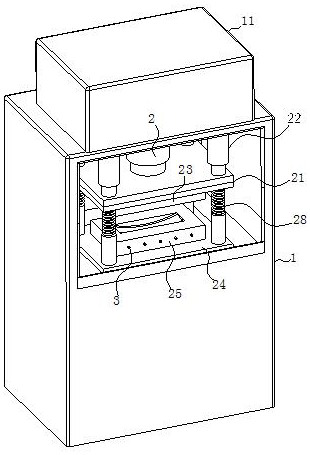

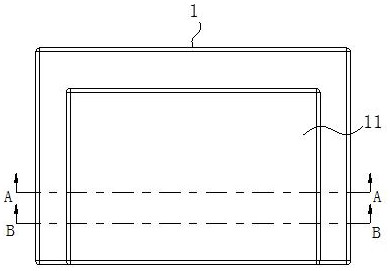

Stamping forming die for automobile front cross beam pipe

An automobile front beam and stamping forming technology, applied in the field of stamping dies, can solve problems such as the influence of forming die production and the increase of die manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

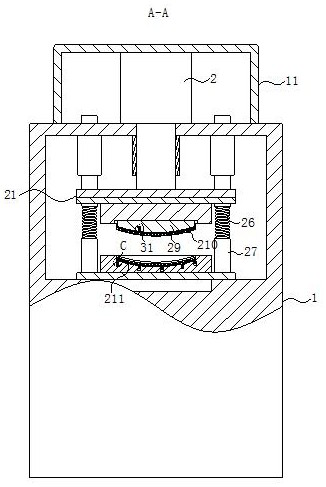

[0025] As an embodiment of the present invention, the upper surface of the first shaped plate 210 is fixed with evenly arranged first ribs; the first ribs are all designed in an arc-shaped structure, and are distributed in the left and right directions; The upper surface of the fixed shaped plate 29 is provided with a first support groove at the position of the first rib; the lower surface of the second shaped plate 211 is fixedly connected with a second rib; the second rib is an arc shaped structure design, and distributed design in the left and right directions; the upper surface of the lower mold 25 is provided with a second support groove at the position of the second rib plate; Respectively fixing the first rib and the second rib can reduce the problem of large deformation of the first shaped plate 210 and the second shaped plate 211, and at the same time insert the first rib and the second rib into the first The inside of the support groove and the second support groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com